Socks and other footwear with selective friction reducing features

a technology of friction reduction and socks, applied in the field of socks and other footwear with selective friction reduction features, can solve the problems of difficulty in getting difficulty in particular individuals' placement etc., to achieve the effect of convenient passage of the foot into outer footwear, low frictional characteristics, and sufficient structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

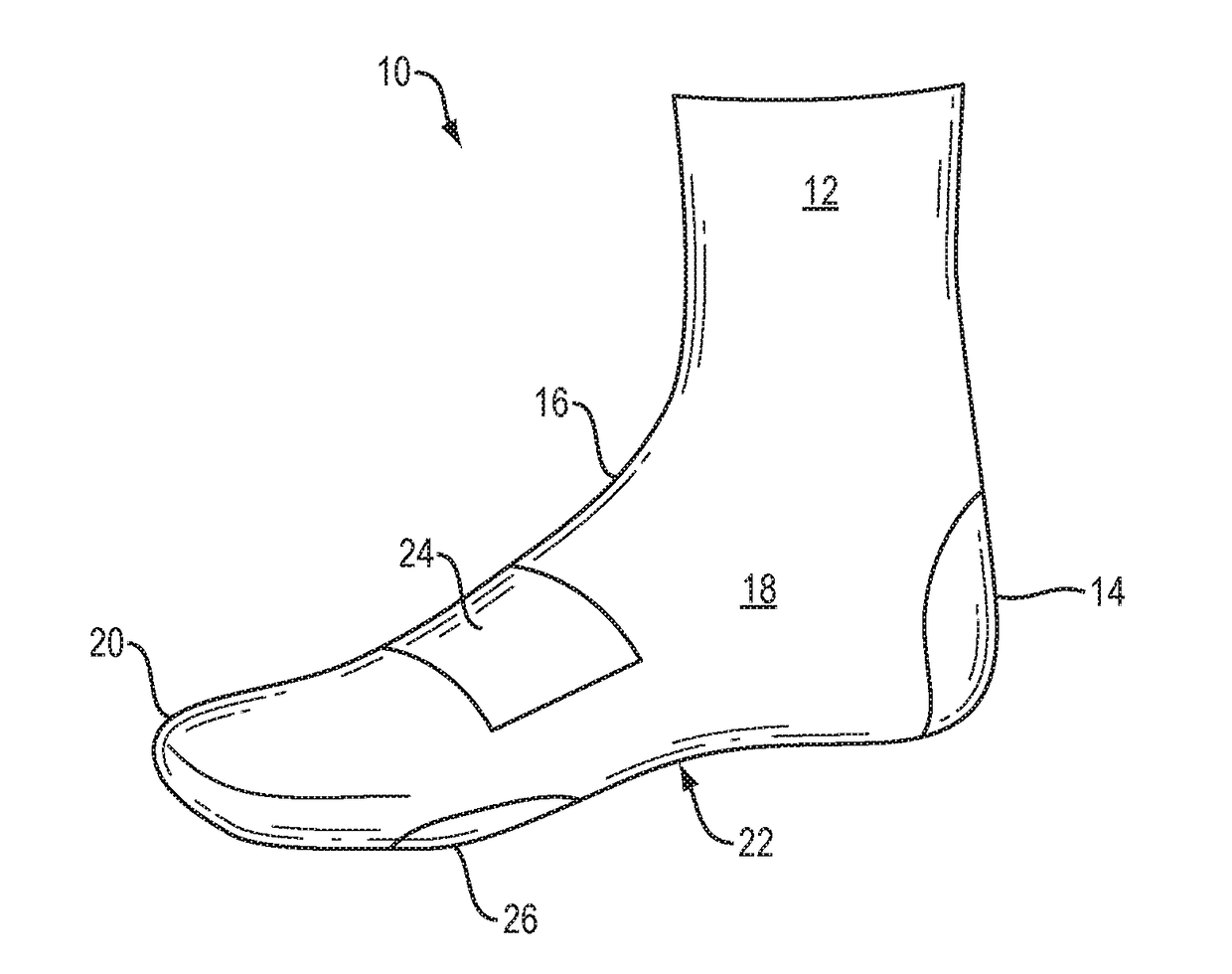

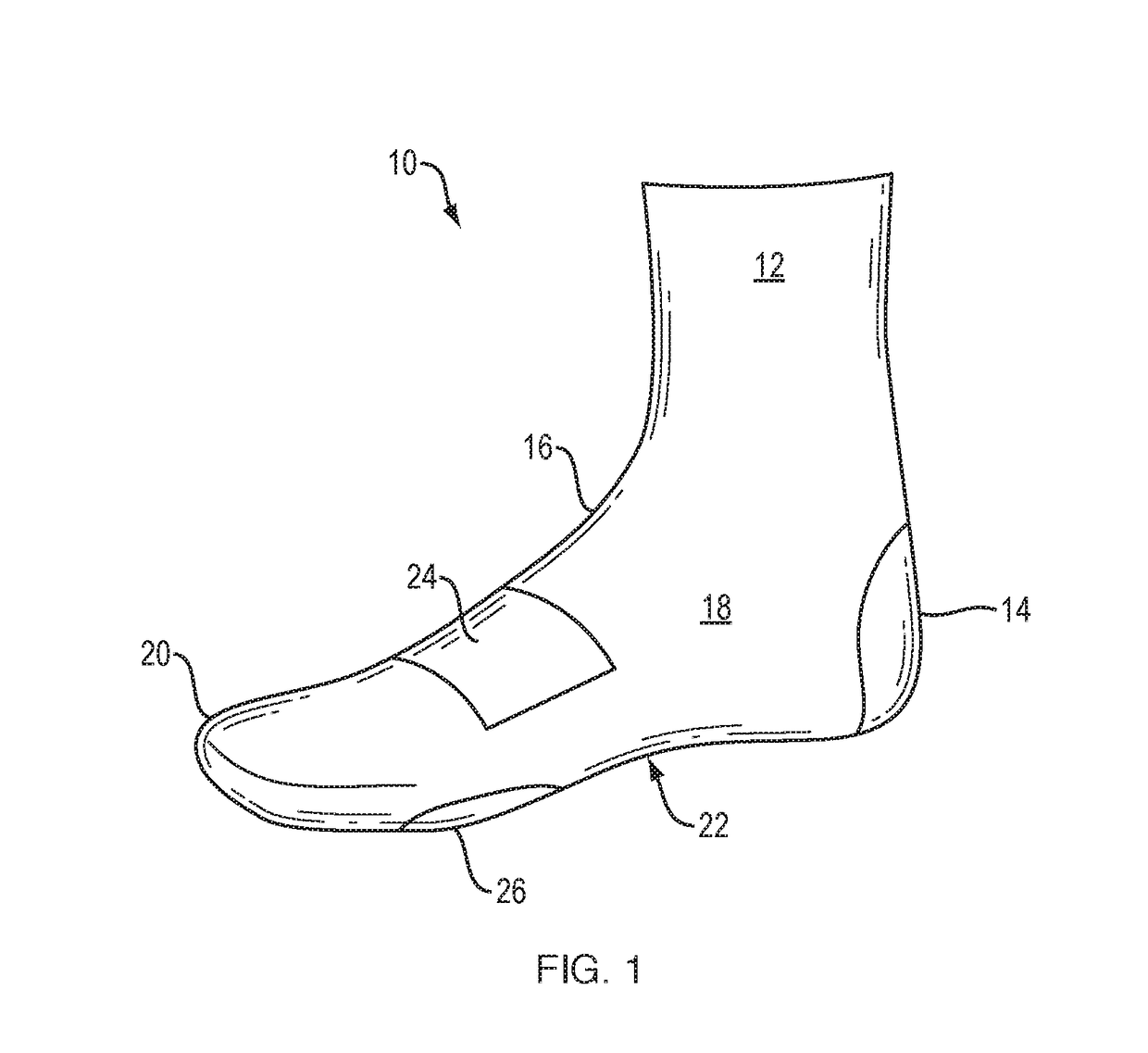

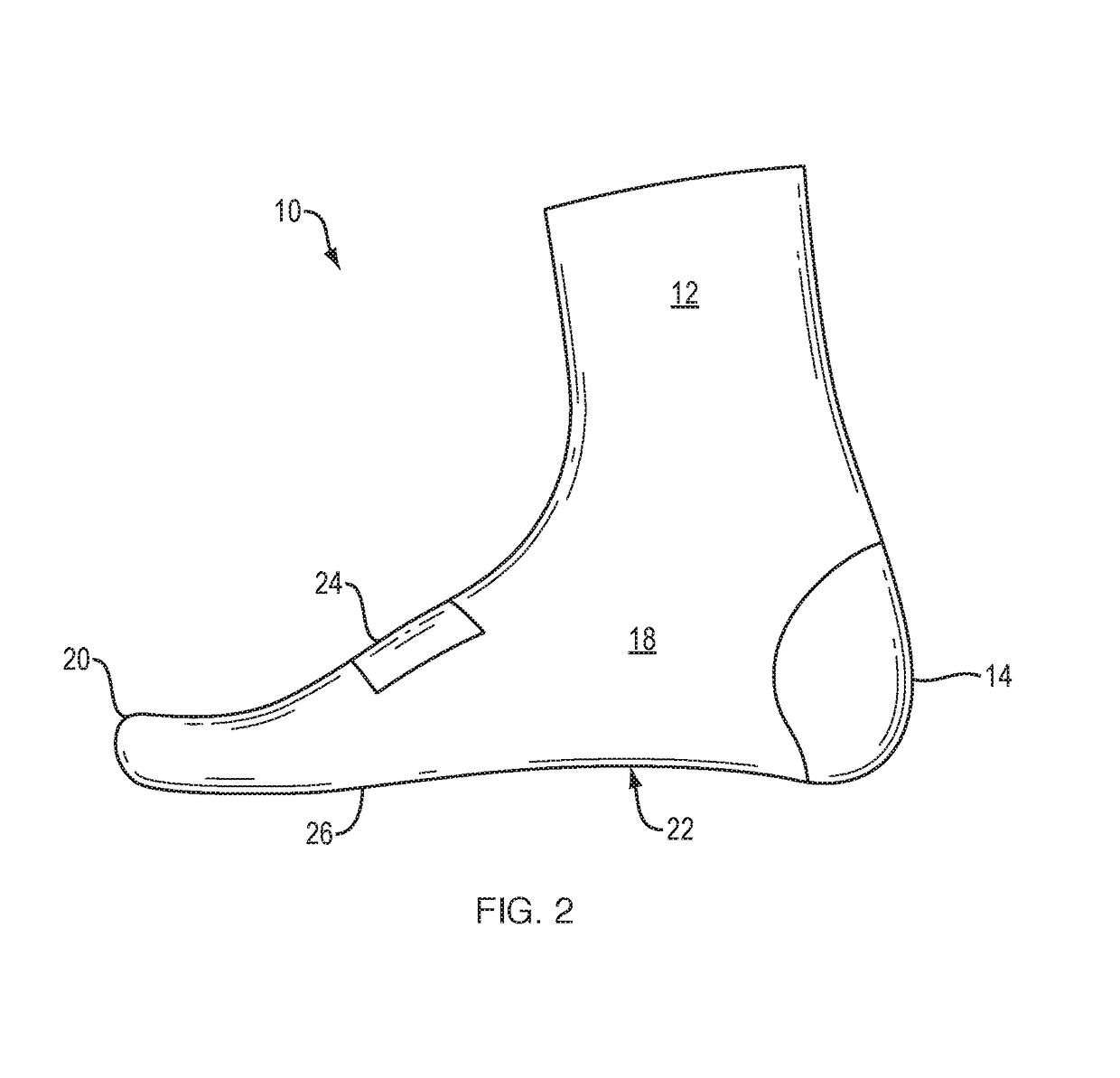

Image

Examples

first embodiment

[0034]In the footwear 100, at least one of the interior heel 106, the top arch portion 120 and the ball portion 122 is fabricated with a low-friction material applied to a portion or substantially all of the surface of such one or more portions. The low-friction material may be a viscoelastic material or a non-viscoelastic material having a low coefficient of friction. For example, the material may be silicone. Alternatively, the low-friction material may be a spray-on material adhered to the interior surface of the footwear 100 at one or more of the interior heel 106, the top arch portion 120 and the ball portion 122. The spray-on material may be a Teflon® spray material but not limited thereto. The low-friction material may also come in a tape form that may be attached to the interior of the footwear 100 at one or more desired locations. The low-friction material applied to the interior of the footwear 100 at one or more of the indicated portions may also be a metallic or a nonmet...

second embodiment

[0035]In the footwear 100, at least one of the interior heel 106, the top arch portion 120 and the ball portion 122 is fabricated with one or more fibers coated with a low-friction material applied to a portion or substantially all of the outer surface of such fibers. The low-friction material may be a viscoelastic material or a non-viscoelastic material having a low coefficient of friction. For example, the material may be silicone. The fibers that are coated may be any manmade or natural fibers. The fibers may be selected from, but are not limited to, cotton and wool. The fibers may also be silicone fibers. The coated fibers may be integrated, that is, interspersed, with the other materials used to make the interior of the footwear 100 in the areas where the low-friction coated fibers are located.

third embodiment

[0036]In the footwear 100, at least one of the interior heel 106, the top arch portion 120 and the ball portion 122 is fabricated with one or more low-friction fibers. The one or more low-friction fibers may be any manmade or natural fibers having a coefficient of friction less than the coefficient of friction of the remainder of the material used to make the interior of the footwear 100. The low-friction fibers may be selected from, but are not limited to, silicone, nylon, polyethylene and polypropylene fibers. Other viscoelastic and non-viscoelastic materials may be selected for that purpose. The fibers may; be integrated, that is, interspersed, with the materials used to make the remainder of the interior of the footwear 100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com