Cathode material

a technology of cathode material and cathode layer, which is applied in the direction of electrodes with substrates, electrolysis components, electrodes, etc., can solve the problem of high cost and the amount of pt used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

lectrolysis Method

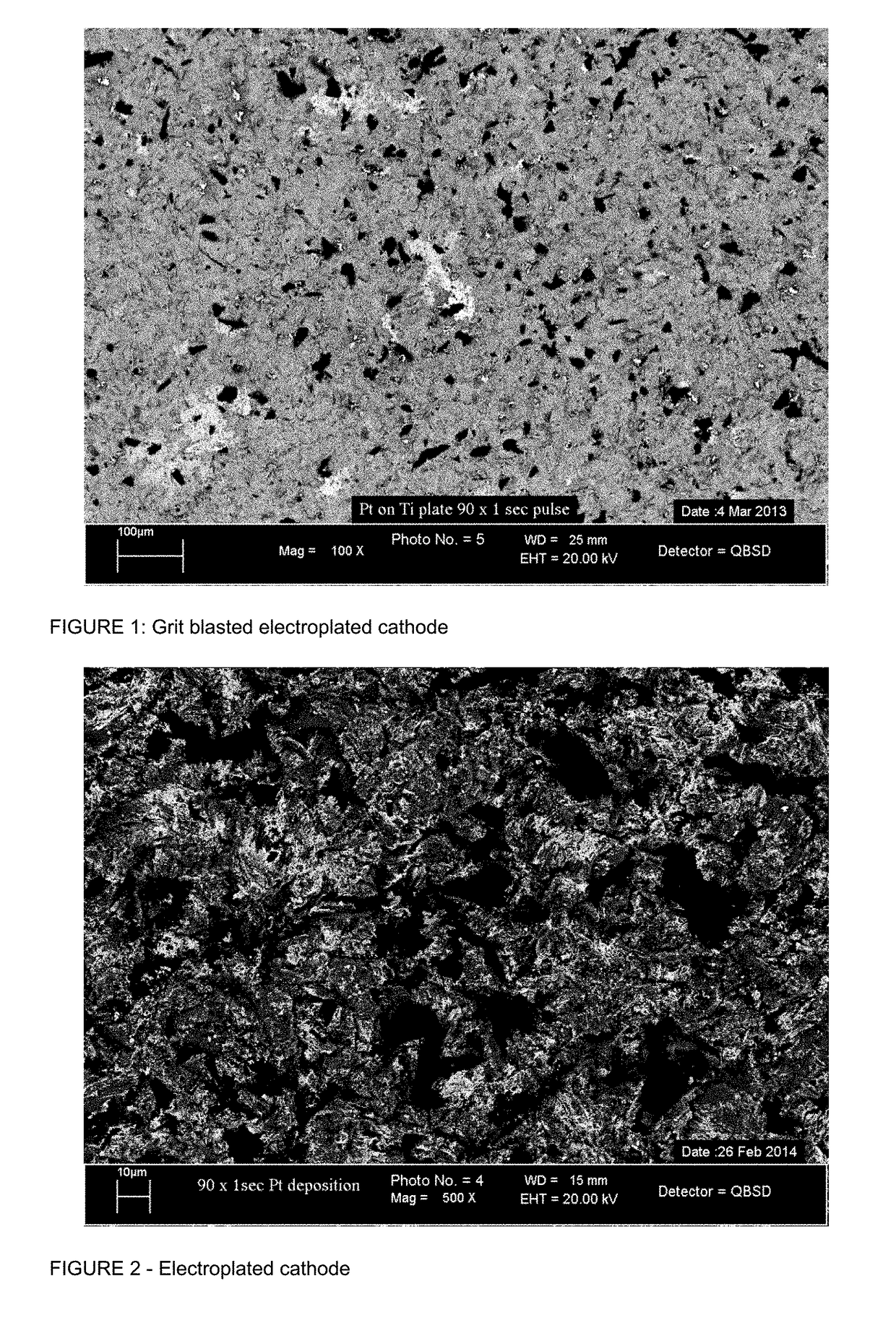

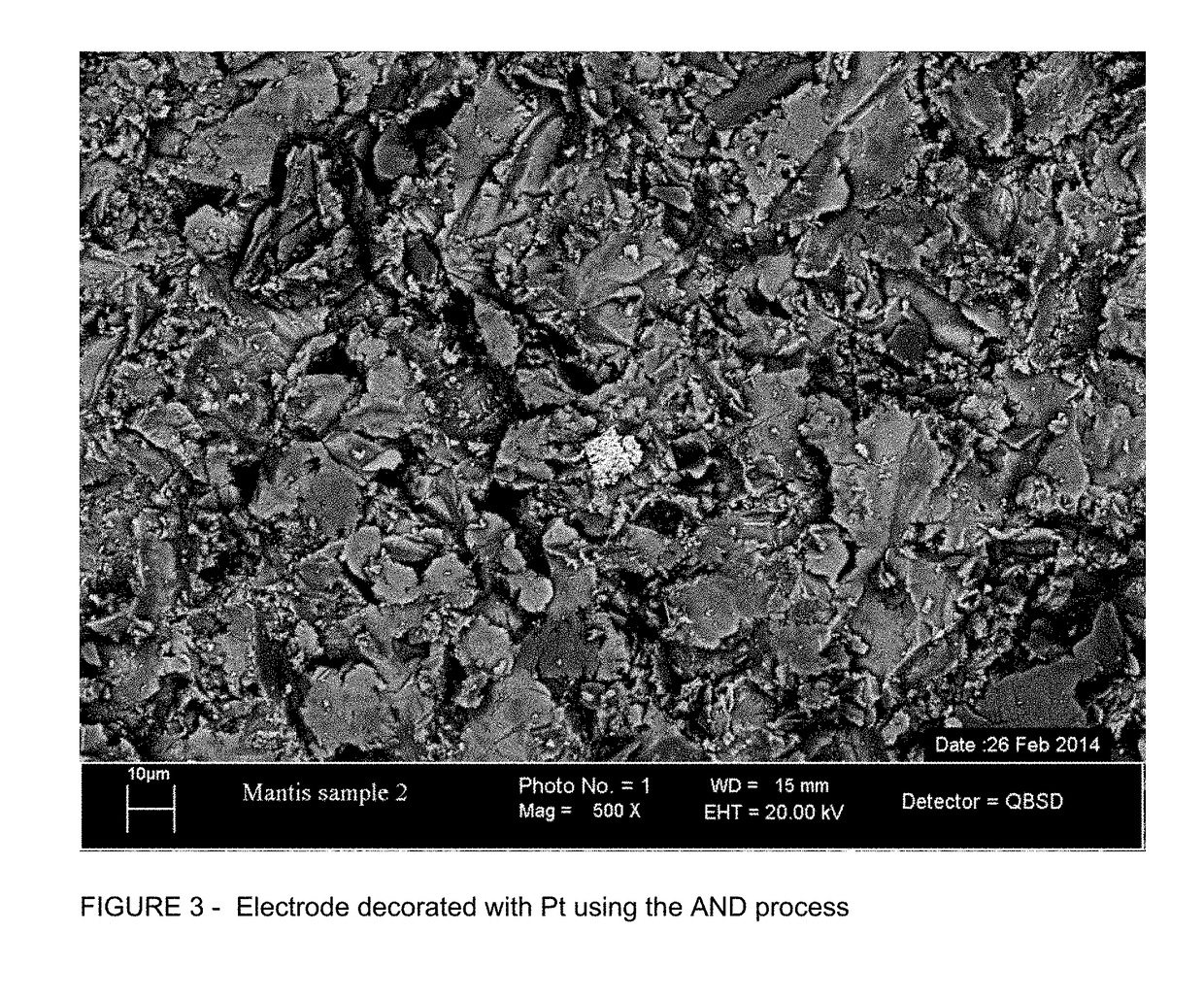

[0046]A grit blasted titanium plate 25 mm×25 mm×1 mm thick was held in tetraammineplatinum hydrogen phosphate solution (Q-salt). A series of 1 second pulses at a current density of 20 mA / cm2 (i.e., one second at 20 mA / cm2 followed by one second at 0 mA / cm2) was passed through the system to build up a Pt decorated surface.

[0047]A series of electrodes were coated. The Pt loadings were measured by XRF.

[0048]FIGS. 1 and 2 illustrate platinum decorated titanium plates in accordance with this Example.

example 2

cle Deposition Methods

[0049]Ti sheet electrodes were decorated with Pt nano-particles using the AND process described above. The gas used to create the plasma to sputter the solid Pt target was argon at a pressure of about 0.1 mbar in the sputtering zone and about 0.001 mbar in the deposition zone. Depositions were carried out at accelerating voltages of 0, 1, 3 and 5 kV for sufficient lengths of time to give the Pt loadings shown in Table 2.

[0050]FIG. 3 illustrates a platinum decorated titanium plate in accordance with this Example.

example 3

Testing

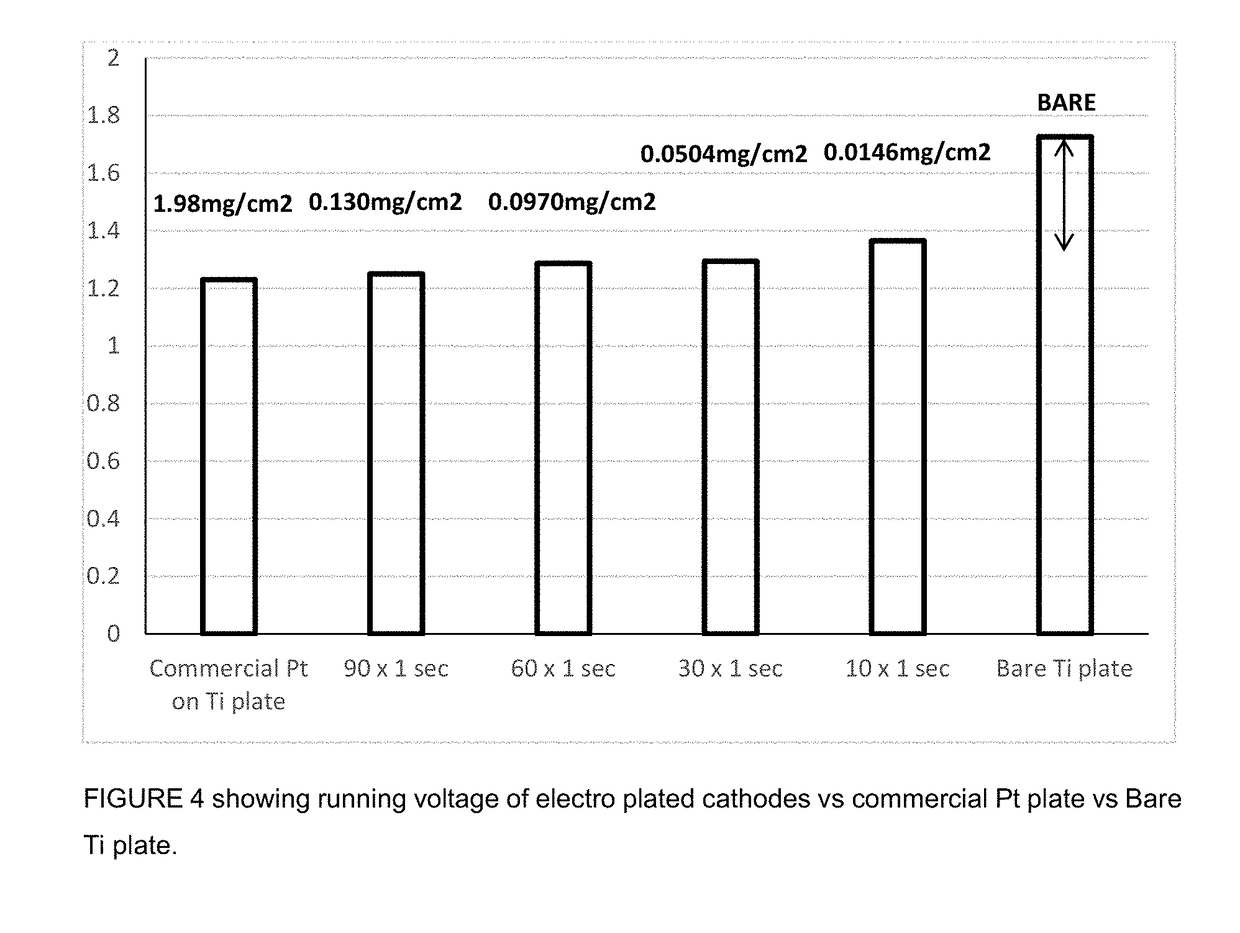

[0051]Electrodeposited cathodes were prepared as in Example 1 herein. Four such cathodes were prepared with varying pulse patterns and platinum loadings:

90×1 sec pulses; Pt loading 0.130 mg Pt / cm2 Ti;

60×1 sec pulses; Pt loading 0.097 mg Pt / cm2 Ti;

30×1 sec pulses; Pt loading 0.0504 mg Pt / cm2 Ti;

10×1 sec pulses; Pt loading 0.0146 mg Pt / cm2 Ti;

[0052]A commercial platinized Ti plate and a bare Ti plate were obtained.

[0053]The cathodes were tested by measuring the operating voltage whilst applying a constant current. The lower the voltage the lower the power consumption [Power (watts)=Voltage (volts)×Current (amps)].

[0054]From FIG. 4 it can be seen that the electro deposited Pt cathodes perform at a comparable voltage to a commercial Pt plated electrode. Even at very low levels of Pt (0.0146 mg / cm2) the electrode remains effective for the hydrogen evolution reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean particle size | aaaaa | aaaaa |

| acceleration voltages | aaaaa | aaaaa |

| geometric area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com