Harvesting atmospheric water using natural gas that would typically be flared and wasted

a technology of atmospheric water and natural gas, which is applied in the field of natural gas flaring, can solve the problems of large amounts of associated gas commonly “flared” or burned up, and achieves significant environmental, thermal and light pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

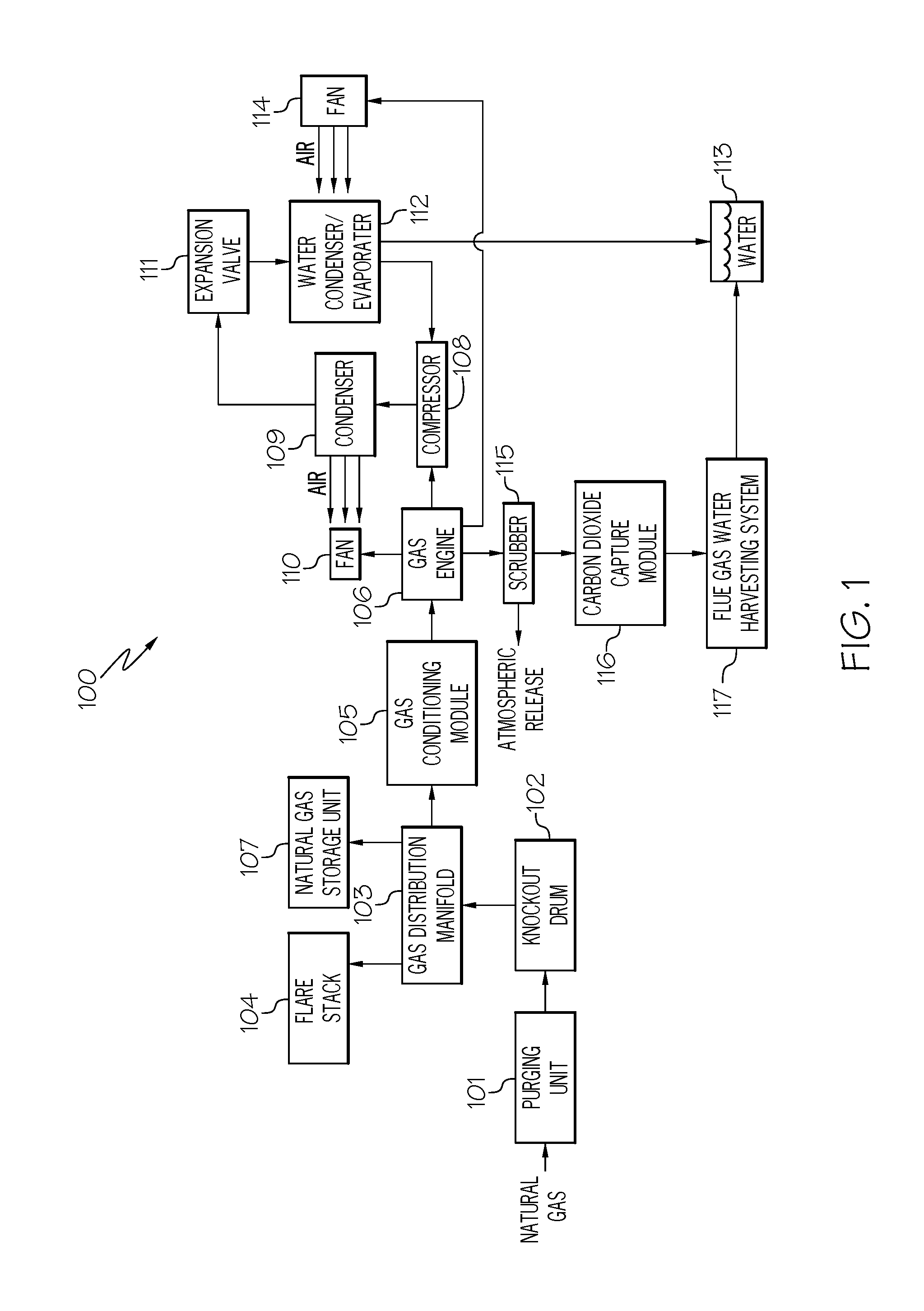

[0013]While the following discusses the present invention in connection with utilizing unwanted natural gas from oil and gas explorations that would typically be flared to harvest water from the atmosphere, the principles of the present invention may be applied to utilizing any unwanted combustible waste gas that would typically be flared to harvest water from the atmosphere. Furthermore, the principles of the present invention may be applied to any unwanted combustible waste gas that would be typically be flared in other industries or plant operations (e.g., petrochemical plant). For example, petrochemical plants typically flare off unwanted natural gas or other combustible gases, which are the byproducts of chemical processes. A person of ordinary skill in the art would be capable of applying the principles of the present invention to such implementations. Further, embodiments applying the principles of the present invention to such implementations would fall within the scope of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com