High-Purity Steviol Glycosides

a technology of steviol glycosides and steviol, which is applied in the direction of transferases, tobacco, tobacco treatment, etc., can solve the problems of unsuitable commercial use methods

- Summary

- Abstract

- Description

- Claims

- Application Information

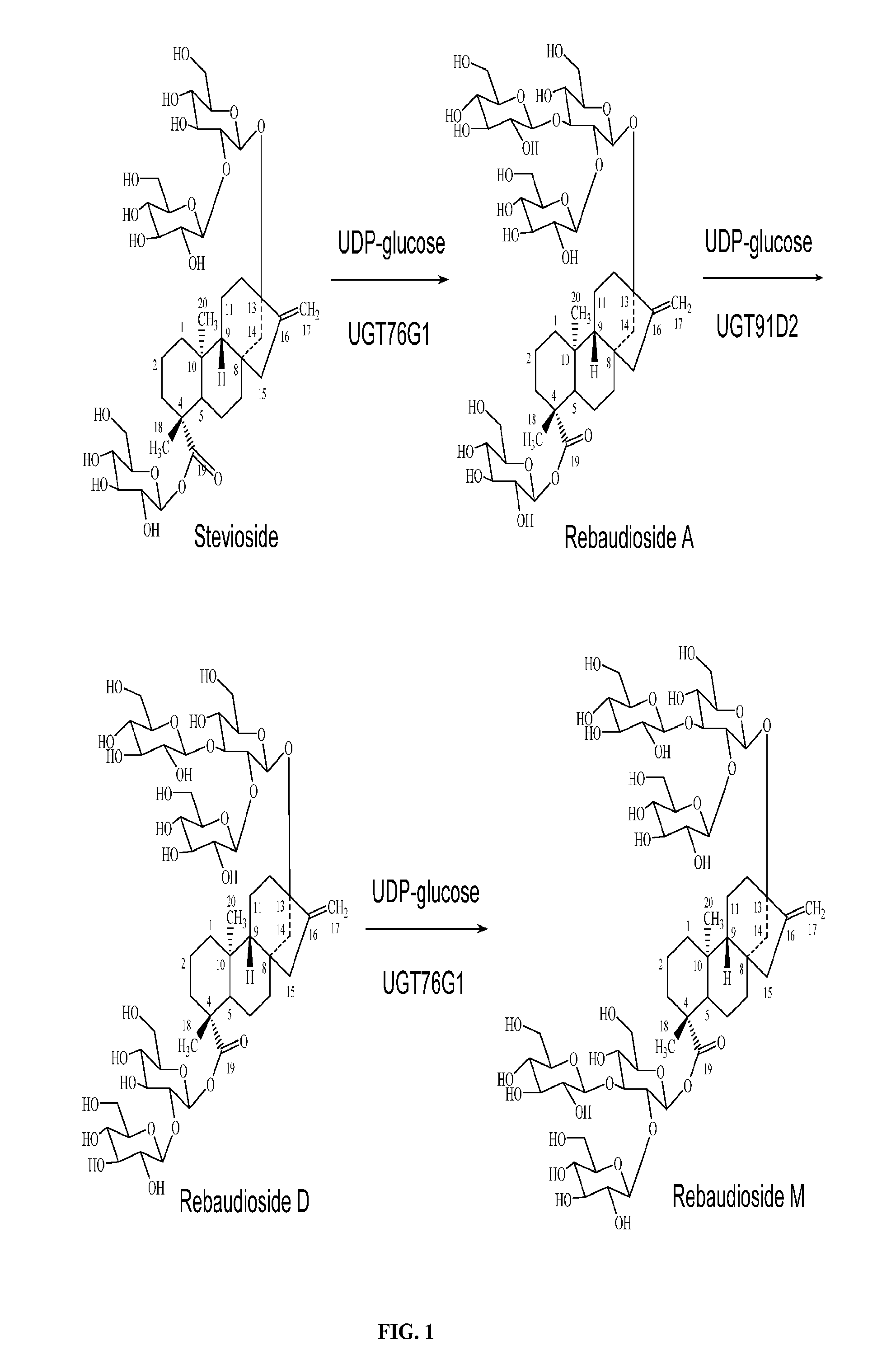

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

In-Vivo Production of UGT76G1

[0285]NcoI and NdeI restriction sides were added to the original nucleic sequence as described in Genbank accession no. AAR06912.1. After codon optimization the following nucleic sequence was obtained:

(SEQ ID NO: 1)CCATGGCCCATATGGAAAACAAAACCGAAACCACCGTTCGTCGTCGTCGCCGTATTATTCTGTTTCCGGTTCCGTTTCAGGGTCATATTAATCCGATTCTGCAGCTGGCAAATGTGCTGTATAGCAAAGGTTTTAGCATTACCATTTTTCATACCAATTTTAACAAACCGAAAACCAGCAATTATCCGCATTTTACCTTTCGCTTTATTCTGGATAATGATCCGCAGGATGAACGCATTAGCAATCTGCCGACACATGGTCCGCTGGCAGGTATGCGTATTCCGATTATTAACGAACATGGTGCAGATGAACTGCGTCGTGAACTGGAACTGCTGATGCTGGCAAGCGAAGAAGATGAAGAAGTTAGCTGTCTGATTACCGATGCACTGTGGTATTTTGCACAGAGCGTTGCAGATAGCCTGAATCTGCGTCGTCTGGTTCTGATGACCAGCAGCCTGTTTAACTTTCATGCACATGTTAGCCTGCCGCAGTTTGATGAACTGGGTTATCTGGATCCGGATGATAAAACCCGTCTGGAAGAACAGGCAAGCGGTTTTCCGATGCTGAAAGTGAAAGATATCAAAAGCGCCTATAGCAATTGGCAGATTCTGAAAGAAATTCTGGGCAAAATGATTAAACAGACCAAAGCAAGCAGCGGTGTTATTTGGAATAGCTTTAAAGAACTGGAAGAAAGCGAACTGGAAACCGTGATTCGTGAAATTCCGGCACCGAGCTTTCTGATTCCGCTGCCGA...

example 2

In-Vitro Production of UGT76G1

[0290]The S30 T7 High Yield Protein expression system kit from Promega was used. 4 μg of UGT76G1_pET30a+ plasmid from E. coli EC100 was mixed with 80 μL of S30 premix plus and 72 μL of S30 T7 extract was added. Nuclease-free water was added in order to obtain a total volume of 200 μL and the resulting solution was incubated for 2 h at 30° C. 180 μL was used in the catalytic test reaction.

example 3

In-Vitro Production of UGT91D2

[0291]NcoI and NdeI restriction sides were added to the original nucleic sequence as described in Genbank accession no. ACE87855.1. After codon optimization the following nucleic sequence was obtained:

(SEQ ID NO: 2)CCATGGCACATATGGCAACCAGCGATAGCATTGTTGATGATCGTAAACAGCTGCATGTTGCAACCTTTCCGTGGCTGGCATTTGGTCATATTCTGCCGTATCTGCAGCTGAGCAAACTGATTGCAGAAAAAGGTCATAAAGTGAGCTTTCTGAGCACCACCCGTAATATTCAGCGTCTGAGCAGCCATATTAGTCCGCTGATTAATGTTGTTCAGCTGACCCTGCCTCGTGTTCAAGAACTGCCGGAAGATGCCGAAGCAACCACCGATGTTCATCCGGAAGATATTCCGTATCTGAAAAAAGCAAGTGATGGTCTGCAGCCGGAAGTTACCCGTTTTCTGGAACAGCATAGTCCGGATTGGATCATCTATGATTATACCCATTATTGGCTGCCGAGCATTGCAGCAAGCCTGGGTATTAGCCGTGCACATTTTAGCGTTACCACCCCGTGGGCAATTGCATATATGGGTCCGAGCGCAGATGCAATGATTAATGGTAGTGATGGTCGTACCACCGTTGAAGATCTGACCACCCCTCCGAAATGGTTTCCGTTTCCGACCAAAGTTTGTTGGCGTAAACATGATCTGGCACGTCTGGTTCCGTATAAAGCACCGGGTATTAGTGATGGTTATCGTATGGGTCTGGTTCTGAAAGGTAGCGATTGTCTGCTGAGCAAATGCTATCATGAATTTGGCACCCAGTGGCTGCCGCTGCTGGAAACCCTGCATCAGGTTCCGGTTGTTCCGGTGGGT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wet weight | aaaaa | aaaaa |

| total volume | aaaaa | aaaaa |

| total volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com