Efficient temperature forcing of semiconductor devices under test

a technology of temperature forcing and semiconductor devices, applied in the field of temperature forcing of semiconductor chips and modules, can solve the problems of reducing process efficiency, insufficient to raise the casing temperature, and exothermic process of dut, and achieve the effect of improving the temperature forcing process, reducing device temperature, and enabling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

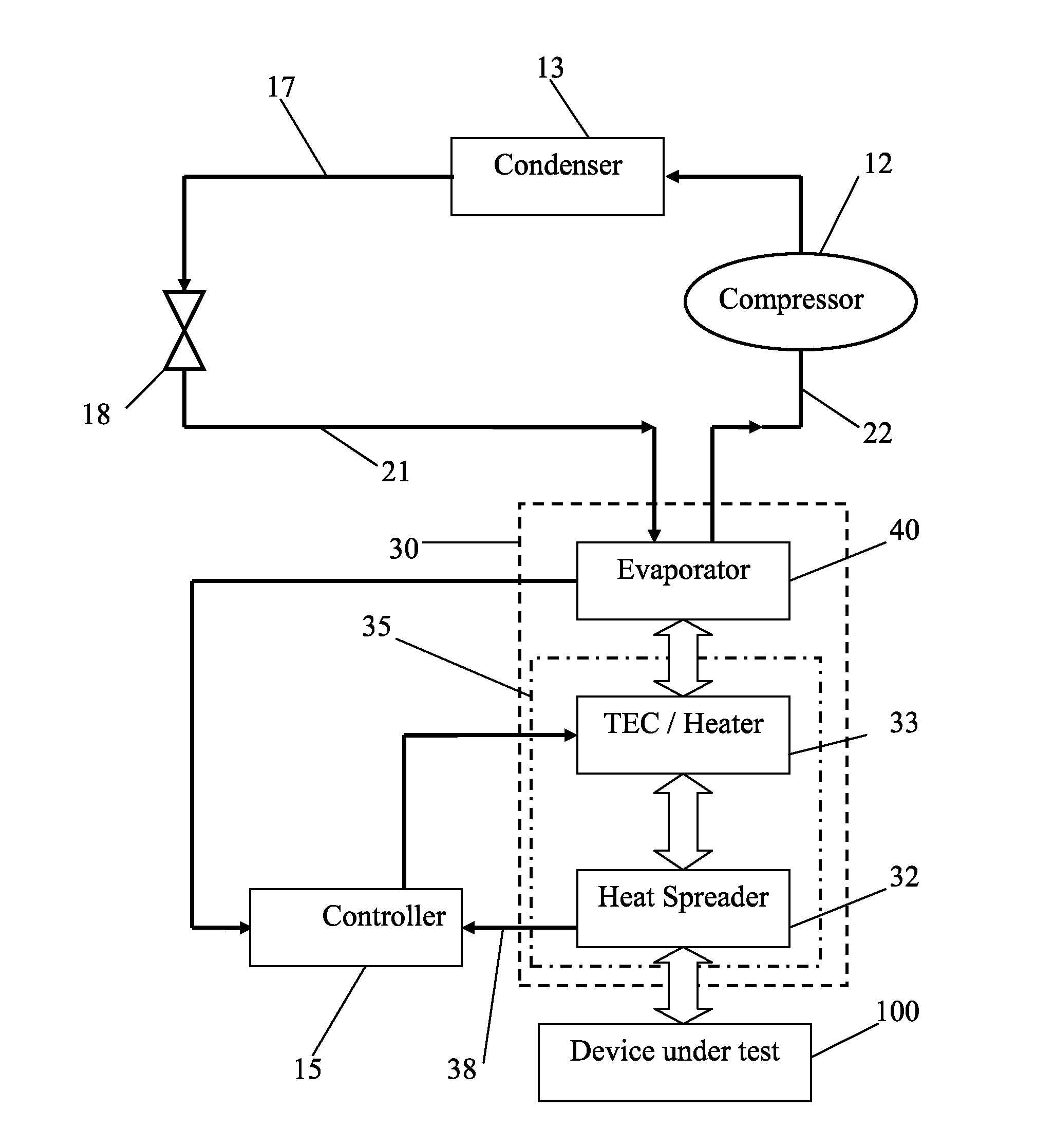

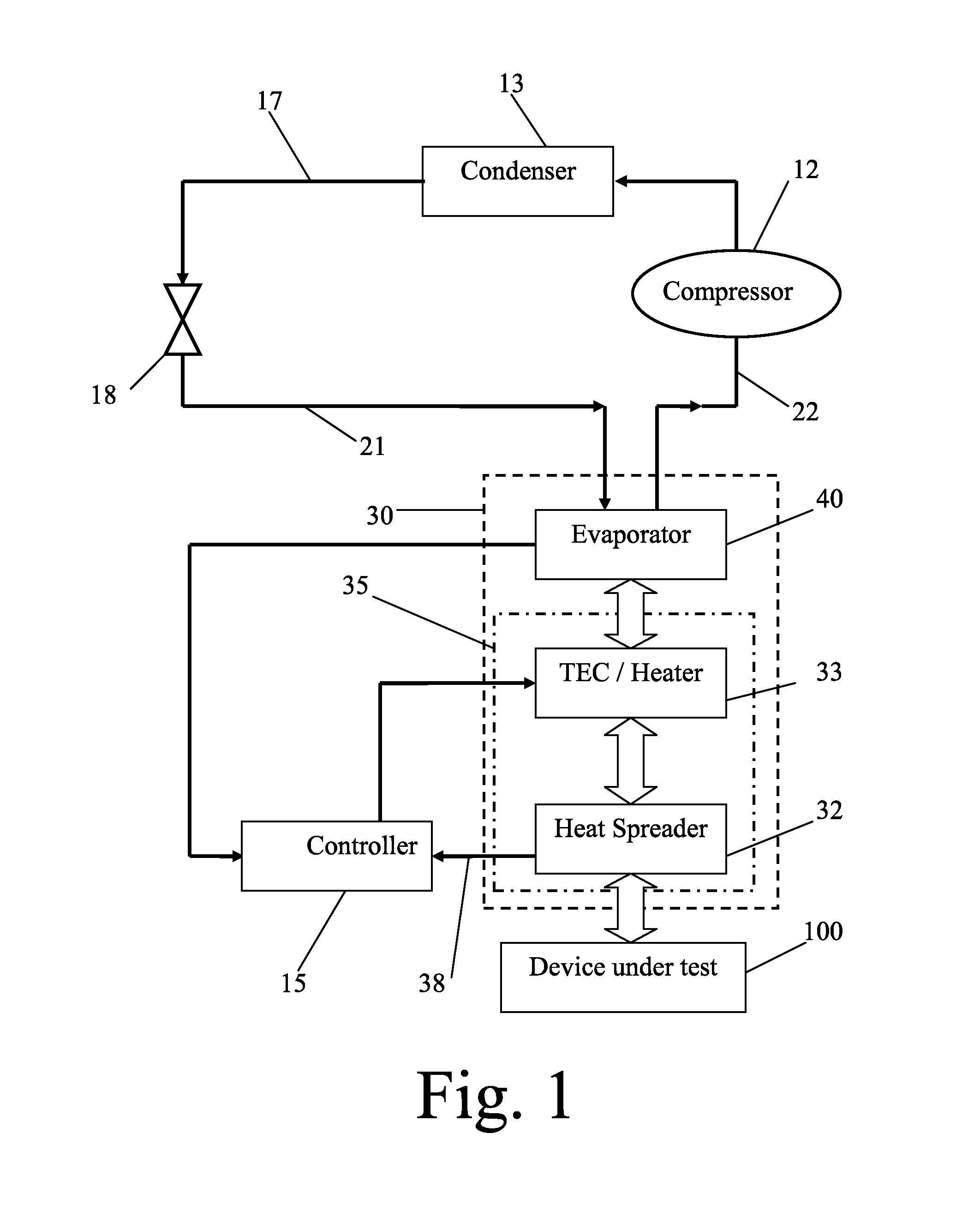

Method used

Image

Examples

example 1

[0077]A field-programmable gate array (FPGA) device was subjected to temperature forcing at extreme temperatures ranging at an extreme high temperature between 135 and 200° C. and at an extreme low temperature between 0 and −60° C. Freon R404A was used as the refrigerant.

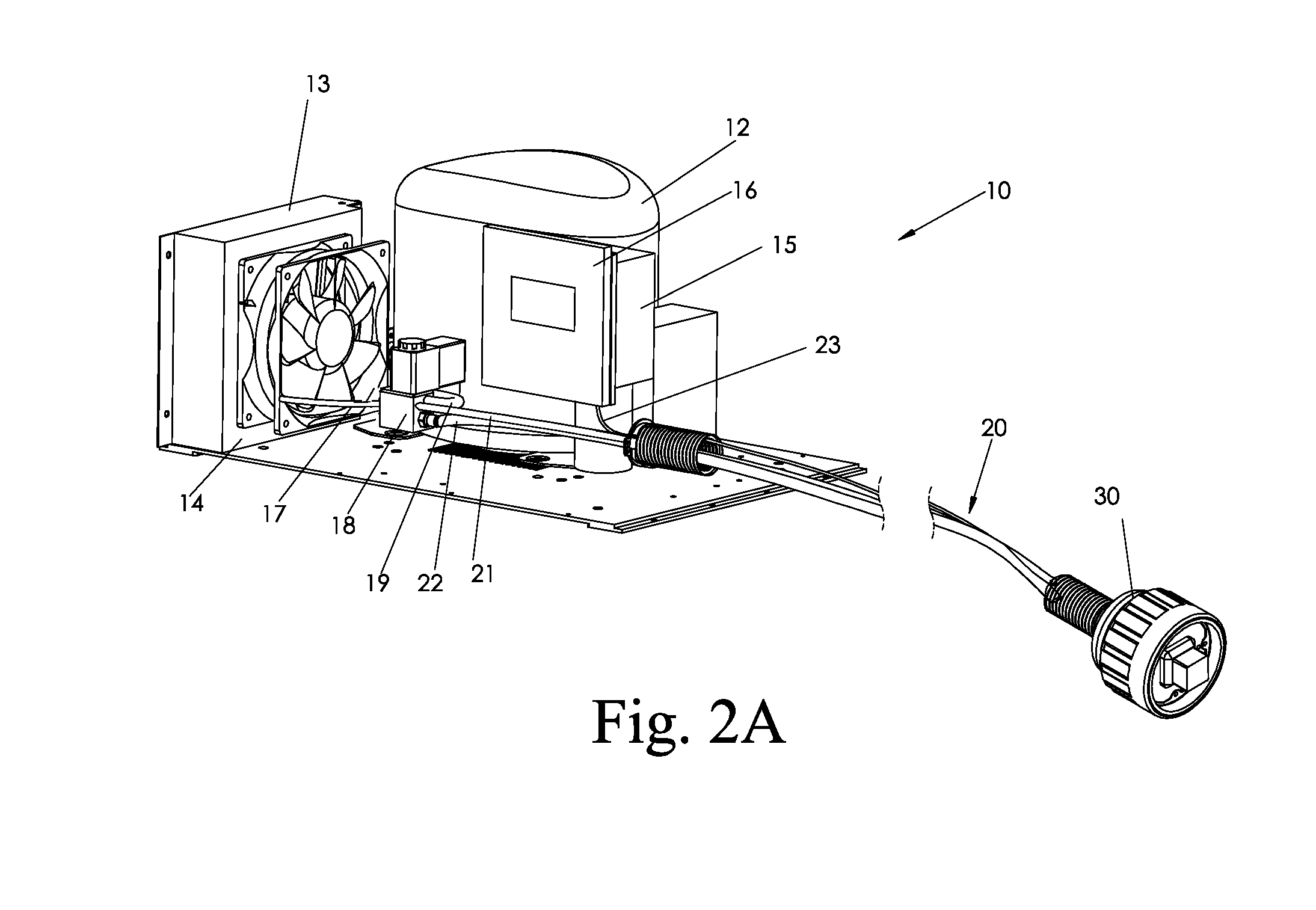

[0078]The compressor pressurized the refrigerant to a pressure of 250-300 psi, resulting in a temperature of 50° C., and provided a suction pressure of 10-20 psi. The refrigerant was cooled by an air-cooled type condenser to a temperature of 30° C. A capillary tube lowered the pressure of the refrigerant to 20 psi and its temperature to −30° C.

[0079]The cooled refrigerant was delivered to a labyrinth type evaporator retained in the temperature-forcing head, and was evaporated as a result of heat transfer from the FPGA device, producing a temperature of −55° C. at a heat dissipation rate of up to 1 kW.

[0080]The compressor operated continuously during the cooling phase, and was not operated during the heating phase. A...

example 2

[0082]A FPGA device was subjected to temperature forcing at extreme temperatures ranging at an extreme high temperature between 135 and 200° C. and at an extreme low temperature between −30 and −70° C. Freon R23 was used as the refrigerant in thermal contact with the device. The temperature-forcing head was not provided with a thermoelectric cooler, but rather the low temperatures were made possible by a two stage refrigeration cycle and the high temperatures were achieved by the use of a resistive heater.

[0083]In the first stage, a first compressor pressurized the R404A refrigerant to a pressure of 250-300 psi, resulting in a temperature of 50° C., and provided a suction pressure of 10-20 psi. The refrigerant was cooled by an air-cooled type condenser to a temperature of 30° C. A capillary tube lowered the pressure of the refrigerant to 20 psi and its temperature to −30° C.

[0084]In the second stage, a second compressor pressurized the R23 refrigerant to a pressure of 400-600 psi, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com