Lead free frangible iron bullets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0030]One grade of iron powder produced by Hoeganaes Corporation was blended with die lubricant, assigned these numbers:

[0031]1) 96.35% iron with 2.90% FE 3 P 16% and 0.75% zinc stearate (lubricant)

[0032]2) The base iron material is trademarked under Hoeganaes Corporations name Anchorsteel 1000C

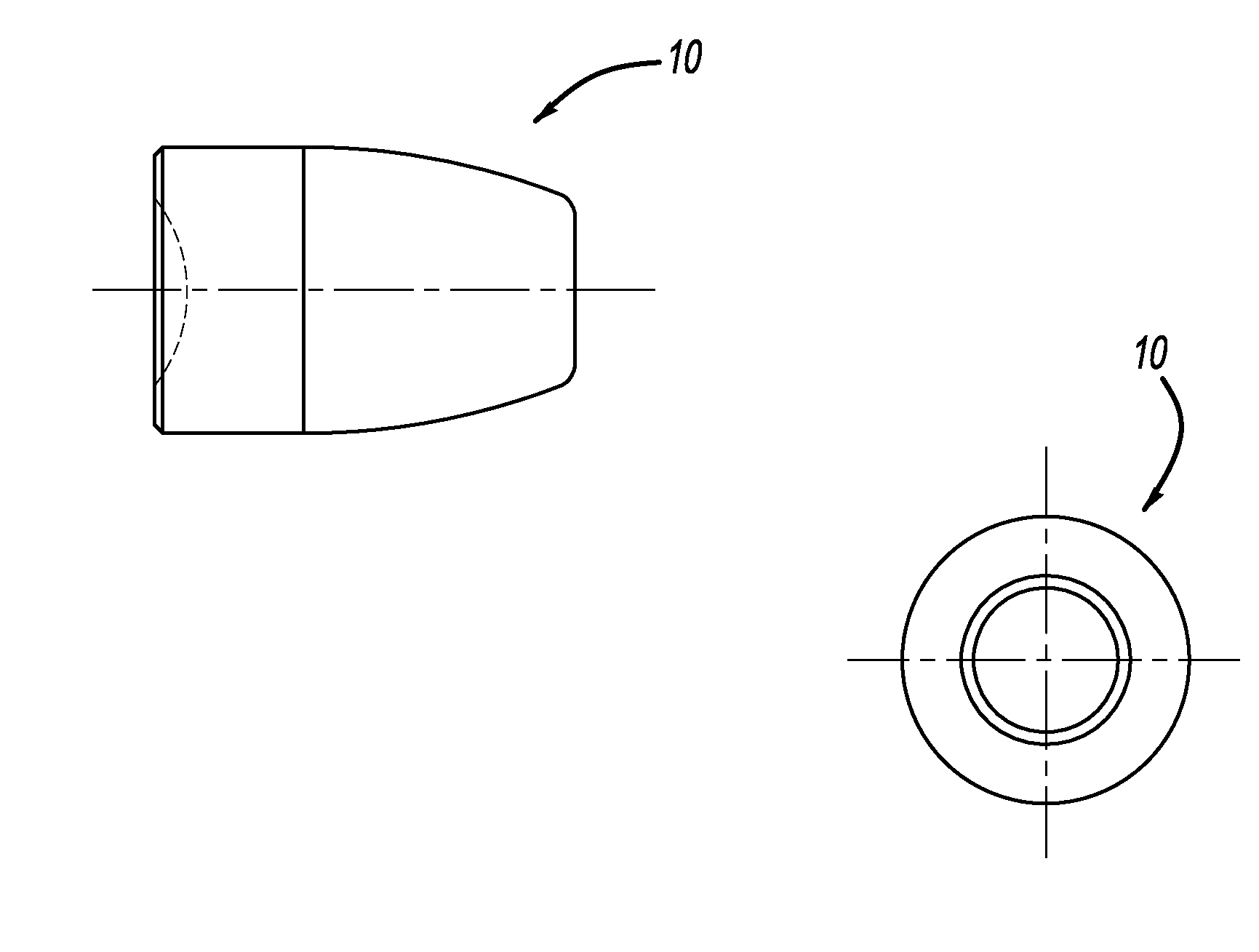

[0033]About a 90 grain sample of the powder blend was pressed (molded) in a die to make the 9 mm projectiles. Projectile size was approximately 9 mm (0.354 inches) diameter×13.5 mm (0.53 inches) long. The bullets were sintered in a belt furnace in a 100% nitrogen atmosphere. Density of bullets was determined using the water immersion technique. Bullets were then resin impregnated and coated with zinc phosphate per MIL-DTL-16232G Class Z Type 2. Other normal plating processes can be used at this point to alter the appearance / color of the bullet. This is followed with a coating or plating using either copper in accordance with ASTM B734-97 Class 5 or coated with manganese phosphate or zinc phos...

example 2

[0046]Additional test firing of bullets made to the same material composition and loading techniques as pre example 1 were conducted. Except in this case the projectiles were copper plated instead of the zinc phosphate coating.

[0047]a) A single test round with the copper plating fragmented as follows:

[0048]Total weight prior to screening=5.54 grams

[0049]Screen powder (or small particles) passing through the 14 mesh screen=1.64 grams (30%)

[0050]Fragments not passing through the 14 mesh screen=3.90 grams (70%)

[0051]The largest fragment size was approximately 0.19×0.18×0.16 inches and weighed no more than 0.55 grams (10%).

example 3

[0052]Additional test firing of bullets made to the same material composition and loading techniques as per example 1 were conducted. Except in this case the projectiles were molded to a longer length of 15 mm (0.59 inches) and were a slightly higher in weight as noted below. Additionally the parts were plated using a standard zinc plating process to 0.0025 inch plating thickness.

[0053]a) A single test round with the zinc plating fragmented as follows:

[0054]Total weight prior to screening=5.67 grams

[0055]Screened powder (or small particles) passing through the 14 mesh screen=4.18 grams (74%)

[0056]Fragments not passing through the 14 mesh screen=1.48 grams (26%)

[0057]The largest fragment size was approximately 0.25×0.20×0.18 inches and weighed no more than 0.28 grams (5%).

[0058]b) A second test of the bullets from example 3 was completed using 10 rounds and the combined weights were recorded.

[0059]Total 10 round weight prior to screening=51.95 grams

[0060]Screened powder (or small par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com