Freestanding Thermoelectric Energy Conversion Device

a conversion device and freestanding technology, applied in the manufacture/treatment of thermoelectric devices, thermoelectric devices with peltier/seeback effects, electrical apparatus, etc., can solve the problems of not being able to stand on its own, increase thermal resistance, increase free convection heat loss, and increase the effect of temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

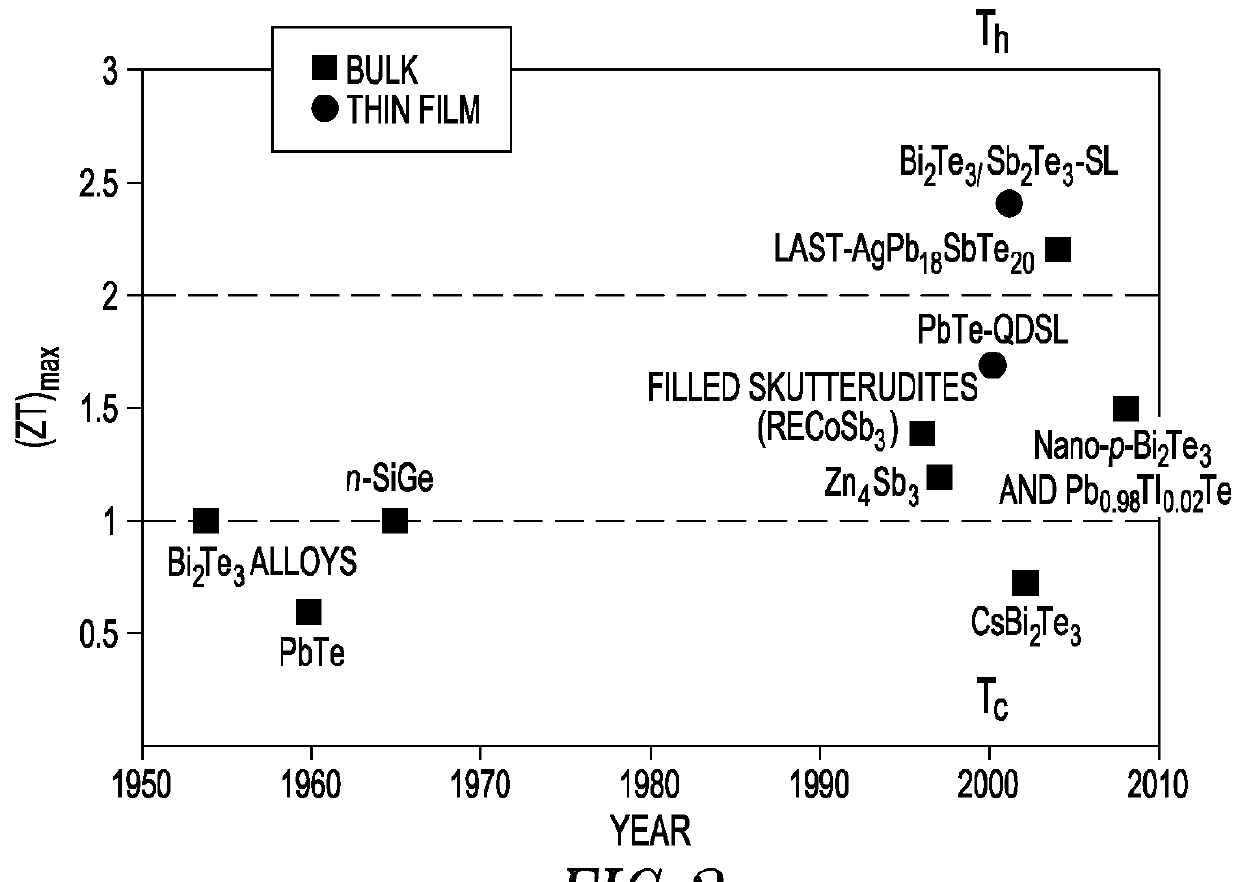

Image

Examples

embodiment 30

[0069]Referring to FIG. 9, another present preferred embodiment 30 has a housing 36 which is placed on a hot surface (not shown). The housing 36 is preferably an electrical insulator with high thermal conductivity such as alumina or boron nitride. It can also be metallic; in that case a thin coating of electrical insulation is necessary. A series of legs 37 extend from opposite sides of the metal housing 36. Each leg consists of an n-type layer 32 and a p-type layer 33 on opposite surfaces of a non-conductive substrate 34. We prefer to use a glass substrate because it can be chemically etched and removed to create open (air) spaces. The distal end of the n-type layer and a p-type layer are connected by a conductor 35 so that current can flow between and through the n-type layer 32 and the p-type layer 33. The legs 37 are attached to the housing in a manner so that the top layer is alternately an n-type layer and a p-type layer. Adjacent legs 37 are connected by a conductor 39 such t...

embodiment 40

[0072]To make the embodiment 40 shown in FIG. 11, one begins with a sheet of material 41 in which half of the sheet is n-type 42 and the other half is p-type 43. Material is removed from the sheet, preferably by laser cutting or by wire saw or by electro-discharge machining, to form a grate 44. The grate 44 consists of a series of bars 46 that extend between an n-side 45 and a p-side 47. The grate 44 is placed on a carrier 48 having an open center to create a subassembly 49. Consequently, air or other fluid can flow freely around and between the bars 46. Two or more subassemblies can be stacked to complete the device.

[0073]Embodiments of the present disclosure are not limited to the above-described examples and emphasized aspects but, rather, may appear in a large number of modifications that lie within the scope of handling by a person skilled in the art. It will be apparent to those skilled in the art that numerous modifications and variations of the described examples and embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com