Hiydrodynamic and hydrosonic cavitation generator

a generator and hydrosonic technology, applied in mixers, heat production devices, heating fuel, etc., can solve the problems of inability to use rotors, bearings and mechanical seals, inability to build, low yield, etc., and achieve the effect of easy and precise adjustment, efficient processing and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

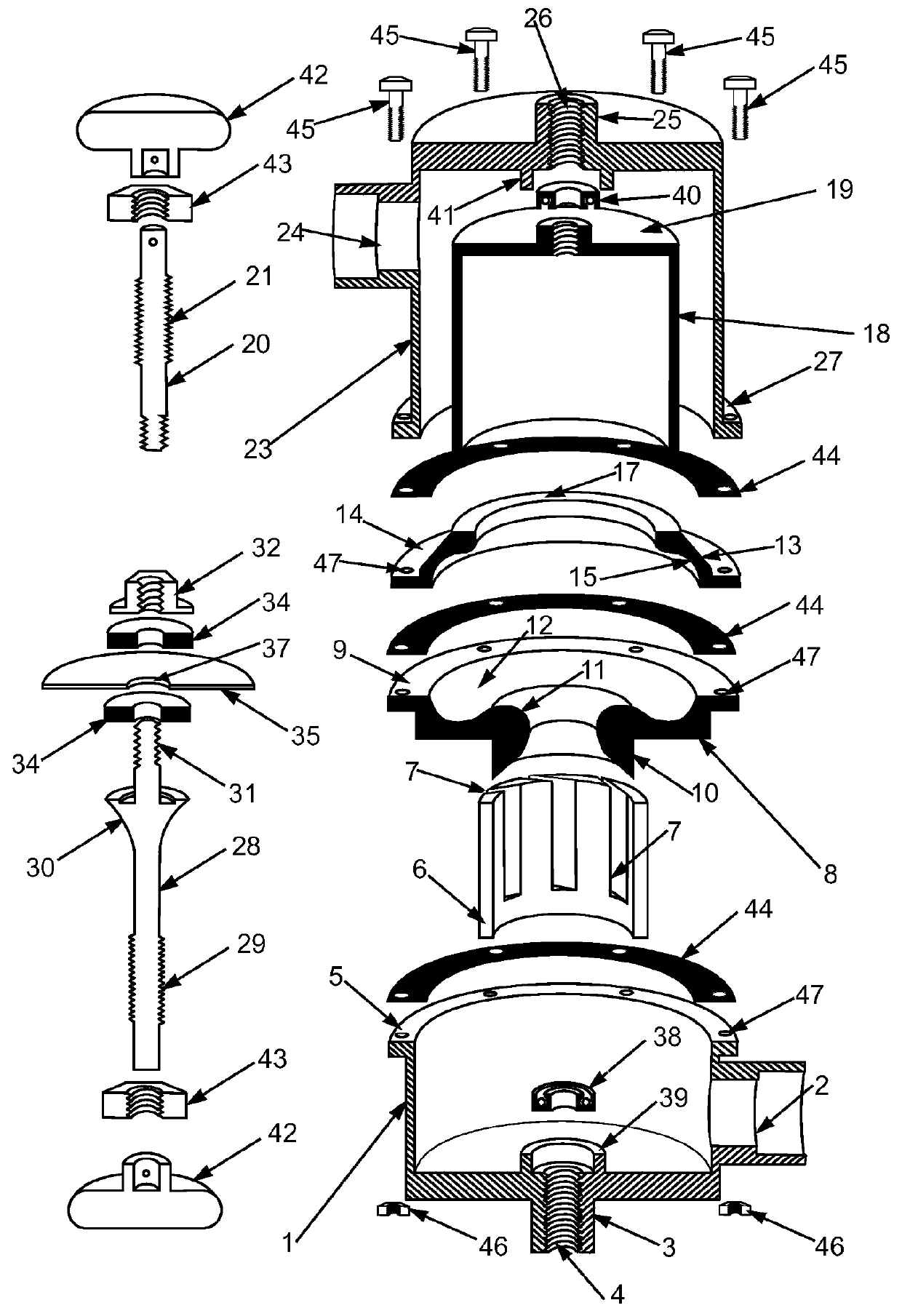

[0024]The present cavitation generator comprises:

[0025]a chamber pot-shaped, preferably cylindrical, said high pressure chamber (1) which is endowed with said feeding tube (2) suitable for connecting the chamber (1) to a pipe; said high pressure chamber (1) is endowed, on its bottom, with a support (3) with a center hole provided with internal screw thread (4) both being coincident with the axis of the chamber (1), which has, at its open end or edge, a flange (5) or other fastening means for to attach it, firmly and sealing, at the whole remainder of the apparatus body; a cylindrical tube that is positioned within said high pressure chamber (1), said vortex tube (6), provided with side openings (7) whose axes are aligned tangentially to the tube (6) circumference;

[0026]one piece said annular divider (8) with discoid shape preferably and shaped flange edges (9), suitable for tightly seal connecting to the flange (5) of said high-pressure chamber (1); said annular divider (7) being pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com