Electric rotisserie

a technology of electric rotisserie and heating element, which is applied in the direction of heating types, household heating details, baking, etc., can solve the problems of affecting the service life affecting the efficiency of the heating element, and affecting the quality of the finished product, so as to reduce the failure rate of heating elements. , the effect of less downtime for parts replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

Pass-Through Embodiment

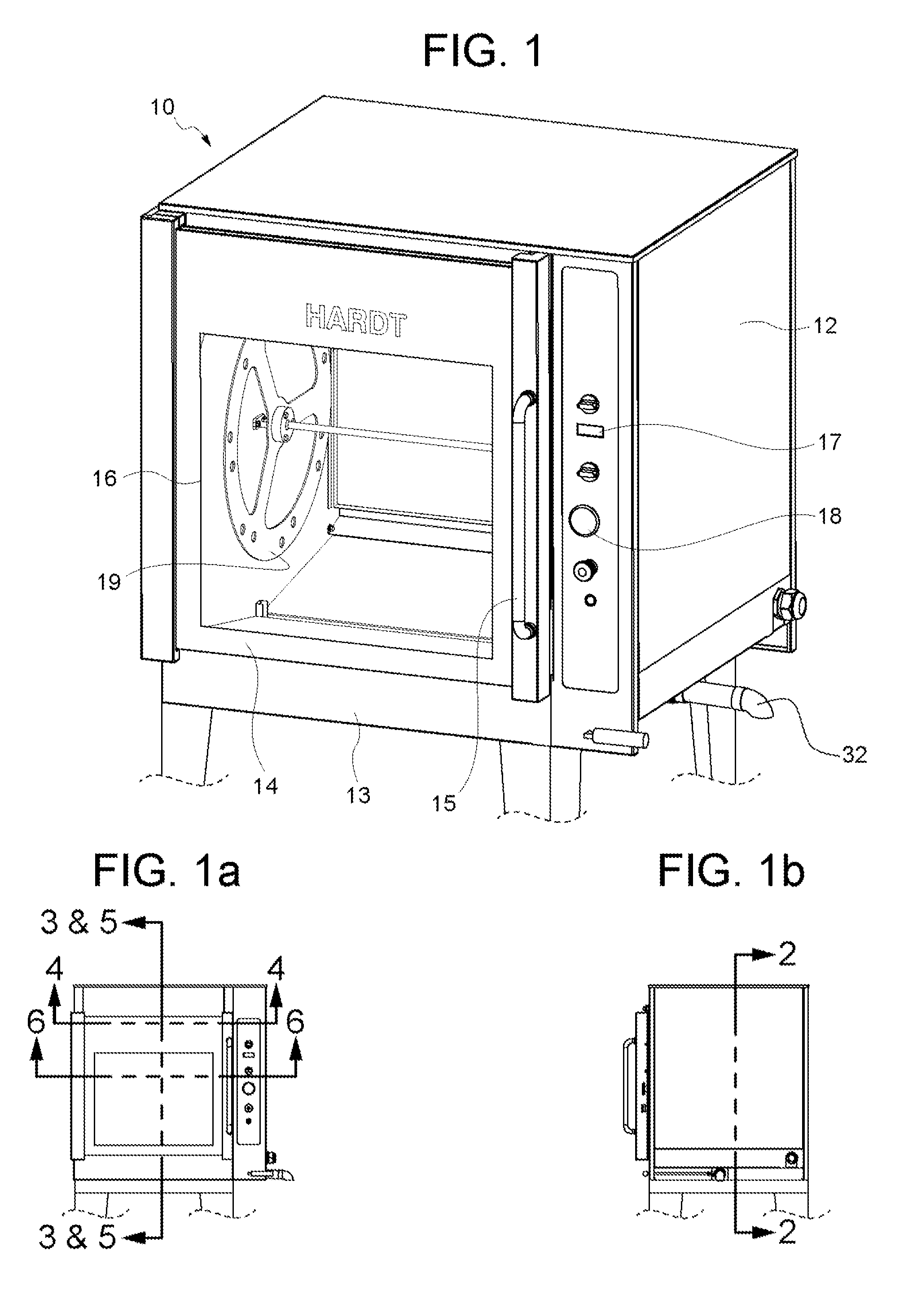

[0067]FIG. 10 depicts a pass-through embodiment of the present invention that features a rear door 75 in conjunction with the front door 14. The two door design allows for pass-through of food items. The advantage of a pass-through design is that the preparation and serving of food can be physically isolated from each other. For example, rotisserie ovens are frequently used to cook chicken. Uncooked chicken is one of the leading causes of salmonella food poisoning. By using a pass-through design, a chef can prepare the uncooked chicken in the kitchen area, while the server can access the cooked chicken from the serving area. In this way, the raw chicken juices and drippings are isolated in the kitchen area, and the risk of salmonella contamination is greatly reduced.

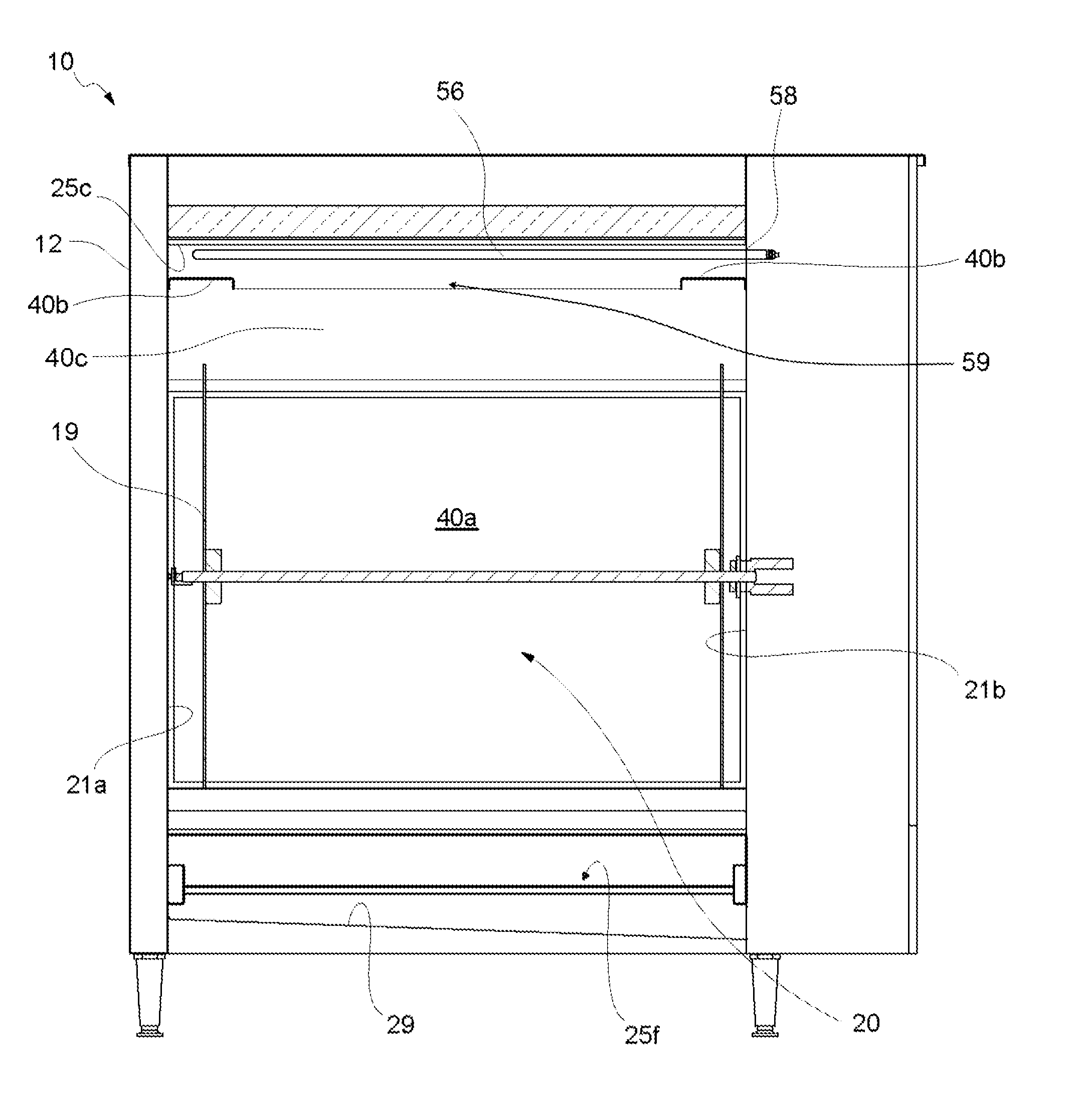

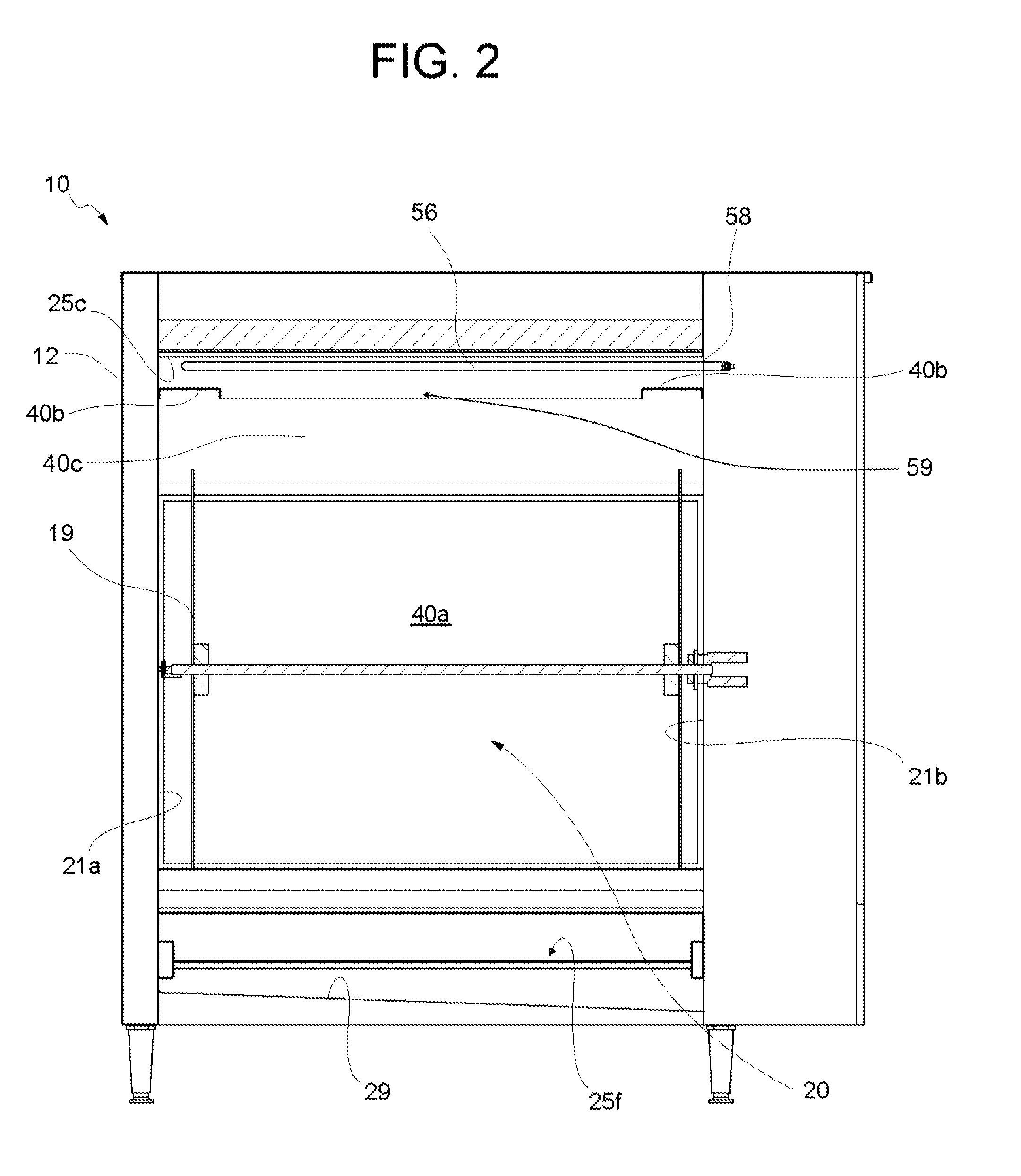

[0068]In the pass through embodiment, the first portion 40b of the dividing member 40 is mechanically joined to the rear door 75. As can be seen in FIG. 5, when the rear door 75 is closed, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com