Enzymatic transesterification/esterification processing systems and processes employing lipases immobilzed on hydrophobic resins

a technology of fatty acid alkyl esters and processing systems, which is applied in the direction of enzymology, biomass after-treatment, enzyme production/based bioreactors, etc., can solve the problems of biocatalysts generally losing their catalytic performance, complex process, and prohibited application of lipases for the production of commercial quantities of fatty acid methyl esters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0165]In this example, three processing systems were tested for a period extending to not less than 262 days.

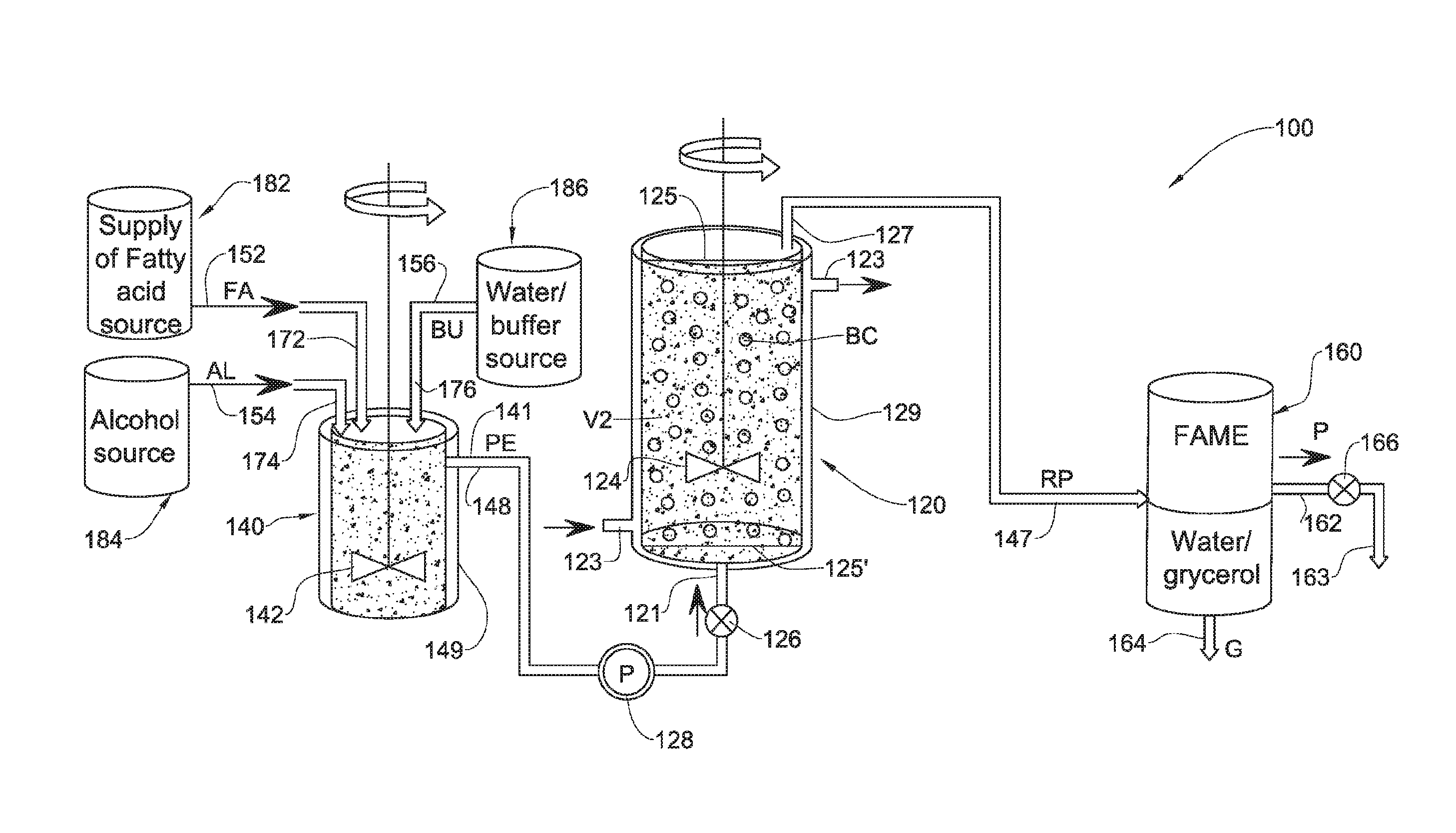

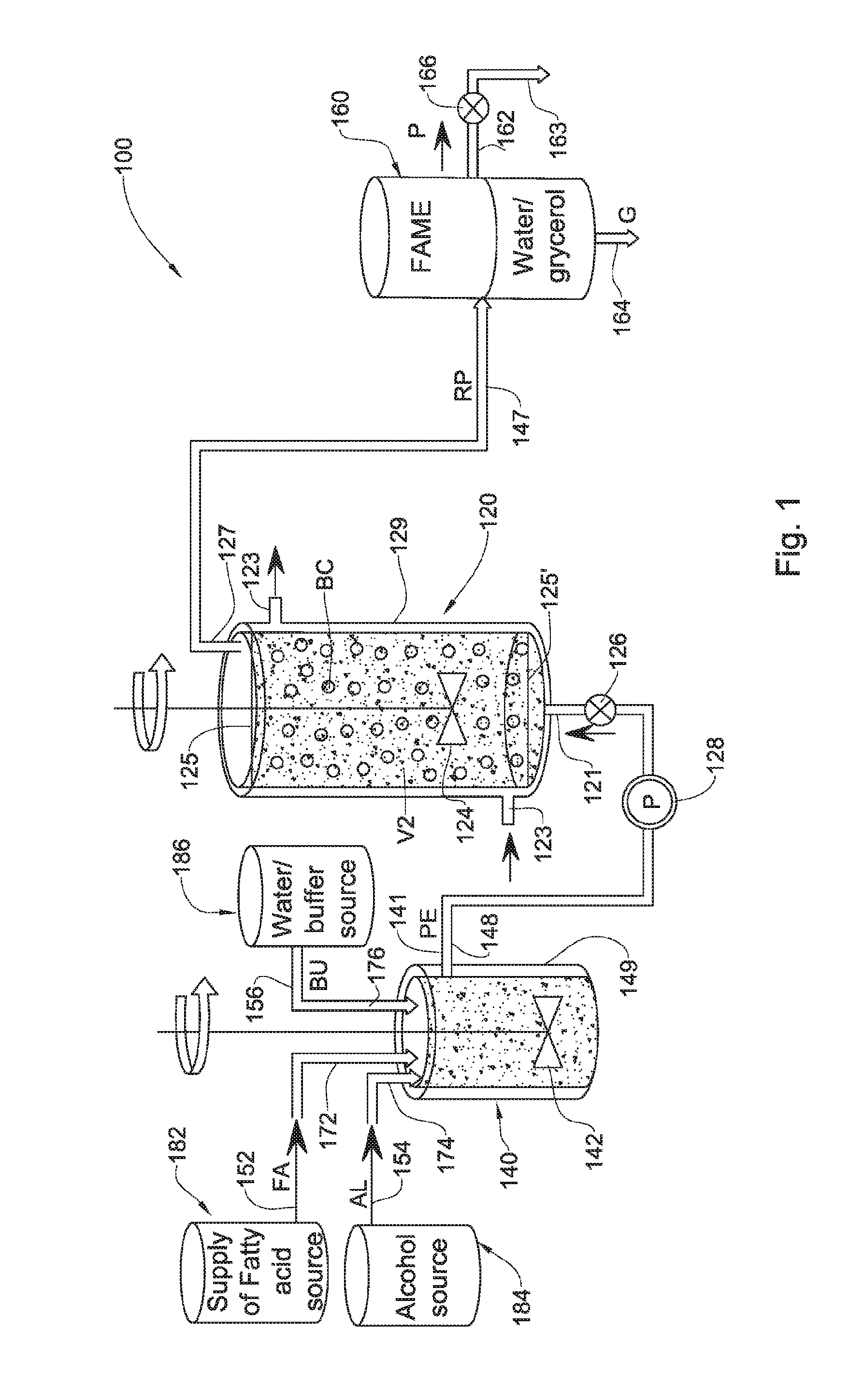

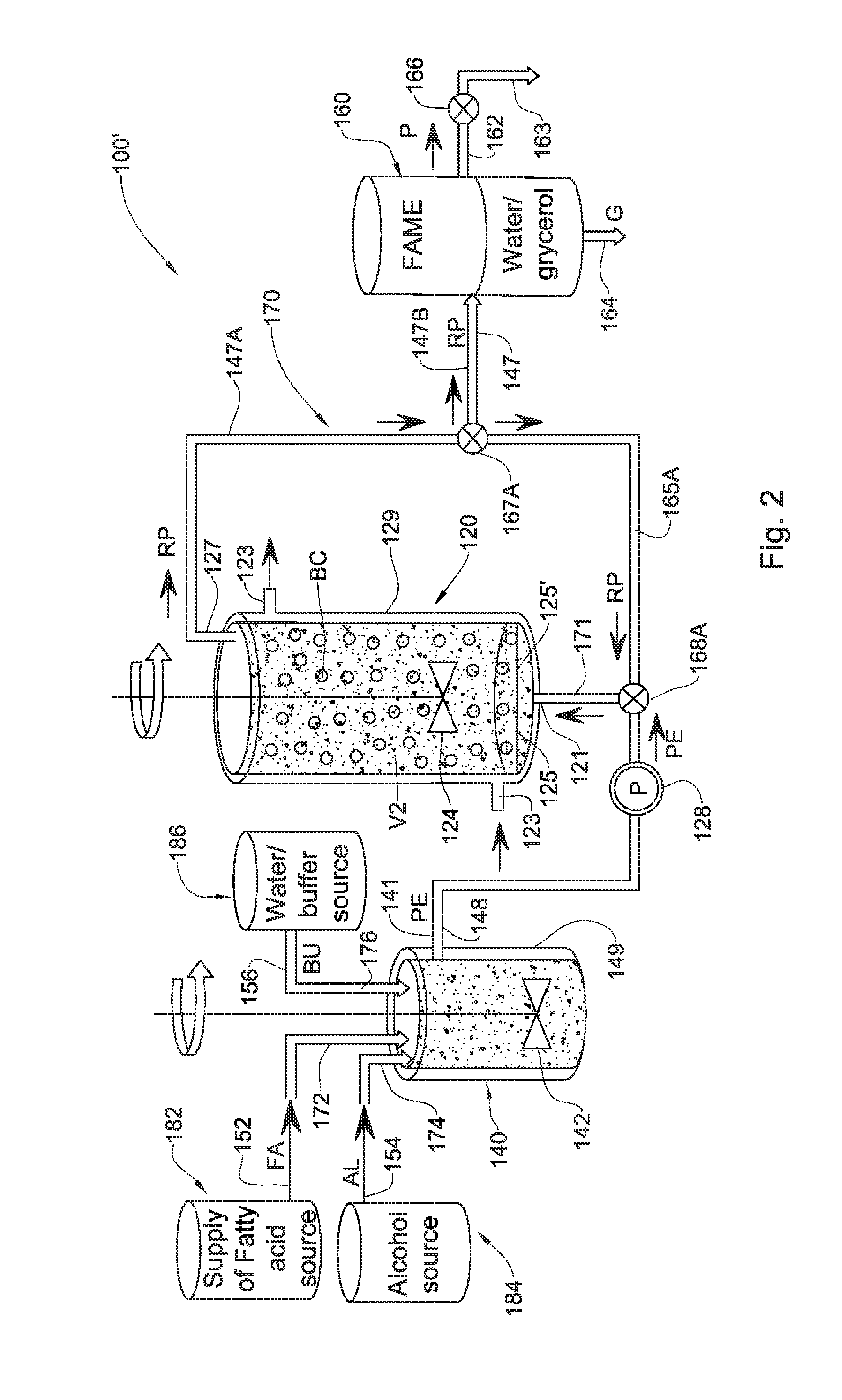

[0166]The first system (herein Example 1(a)) was based on the embodiment of the processing system 100′ illustrated in FIG. 2 with flow through the reactor vessel 120 in a direction generally opposed to gravity (bottom-to-top), and operated at a flow rate of 20 ml / min throughput through the processing system.

[0167]The second system (herein Example 1(b)(i)) served as a control, and was based on a processing system similar to the system 100 of FIG. 1, but with the flow through the reactor vessel in a direction generally aligned with gravity (top-to-bottom), rather than in a direction generally opposed to gravity (bottom-to-top), and operated at a flow rate of 20 ml / min throughput through the respective processing system.

[0168]The third system (herein Example 1(b)(ii)) also served as a control, and was based on a processing system similar to the second system (i.e., with the flow...

example 1 (

Example 1(b(ii))

[0179]The system, reaction conditions and continuous reaction mode of operation used for this example was similar to that of Example 1(b)(i), mutatis mutandis, the only differences being that in Example 1(b)(ii) an emulsified reaction medium (prepared emulsion) containing soybean oil (80% wt), methanol (15%) and 0.1M sodium bicarbonate solution (5%) was continuously fed into the reactor vessel at a flow rate of 10 ml / min rather than 20 ml / min (provided by example 1(b(i)) or example 1(a)).

[0180]Table 1, column 4 shows the conversion of feedstock to fatty acid methyl esters in the above system at a number of days during the 262 day trial.

TABLE 1The conversion of feedstock to fatty acid methyl esters in acontinuous hybrid stirred- and expanded-bed reactor with time VS.control reactor vessel at the same flow rate and at reduced flow rate.Conversion (%)hybrid stirred- andConversion (%)Conversion (%)expanded-bedControl reactor atControl reactor atreactor at flow rateflow r...

example 2

Second Stage Transesterification / Esterification Reaction Using the Effluent of the First Stage

[0181]In this example, three processing systems were tested for a period extending to not less than 121 days.

[0182]The first system (herein Example 2(a)) was based on the system 200′ of FIG. 5 with flow thorough the reactor vessel 120 and in the auxiliary reactor vessel 220 was in a direction generally opposed to gravity (bottom to-top), and operated at a flow rate of 20 ml / min throughput through the system 200′.

[0183]The second system (herein Example 2(b)(i)) served as a control, and was based on a processing system similar to the system 200′ of FIG. 5, but with the flow through the reactor vessel 100, and in the auxiliary reactor vessel 220 being in a direction generally aligned with gravity (top-to-bottom), rather than in a direction generally opposed to gravity (bottom-to-top), and operated at a flow rate of 20 ml / min throughput through the respective system.

[0184]The third system (here...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com