Variable Length Fill Up Tool and Valve

a filling tool and variable length technology, applied in the field of filling tools, can solve the problems of misalignment of top-drive and elevator, huge side load, filling tool, etc., and achieve the effects of low pressure drop, high circulation pressure, and easy lowering of elevators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

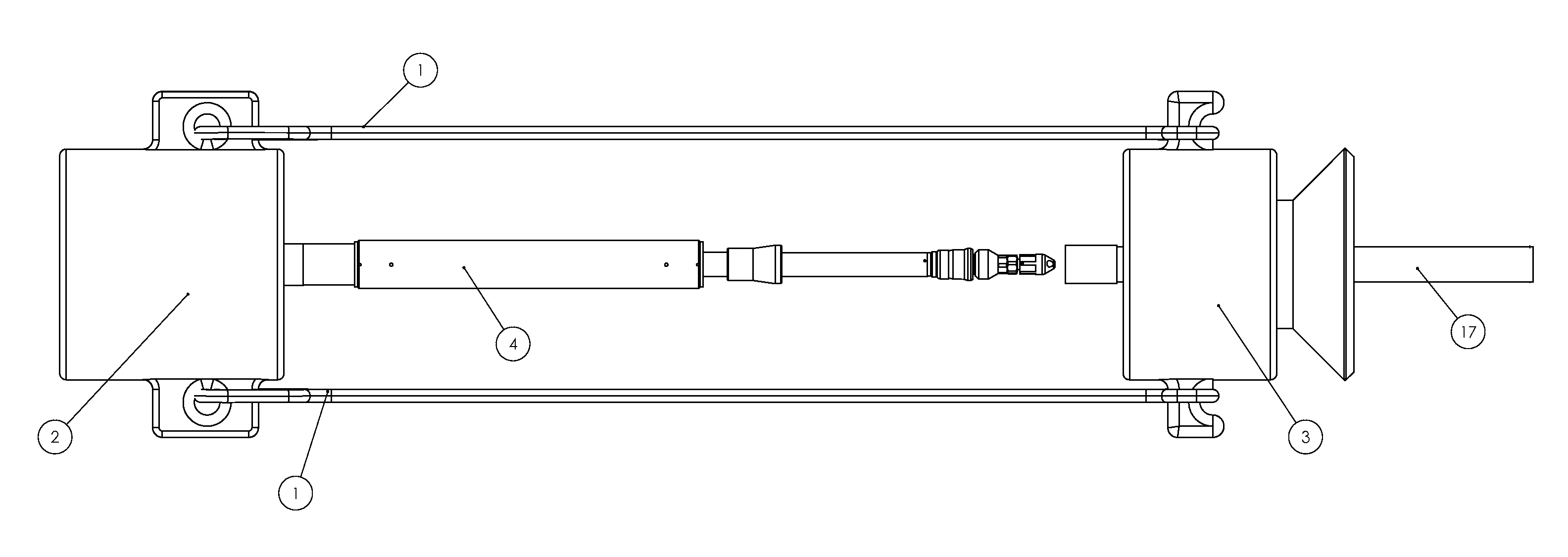

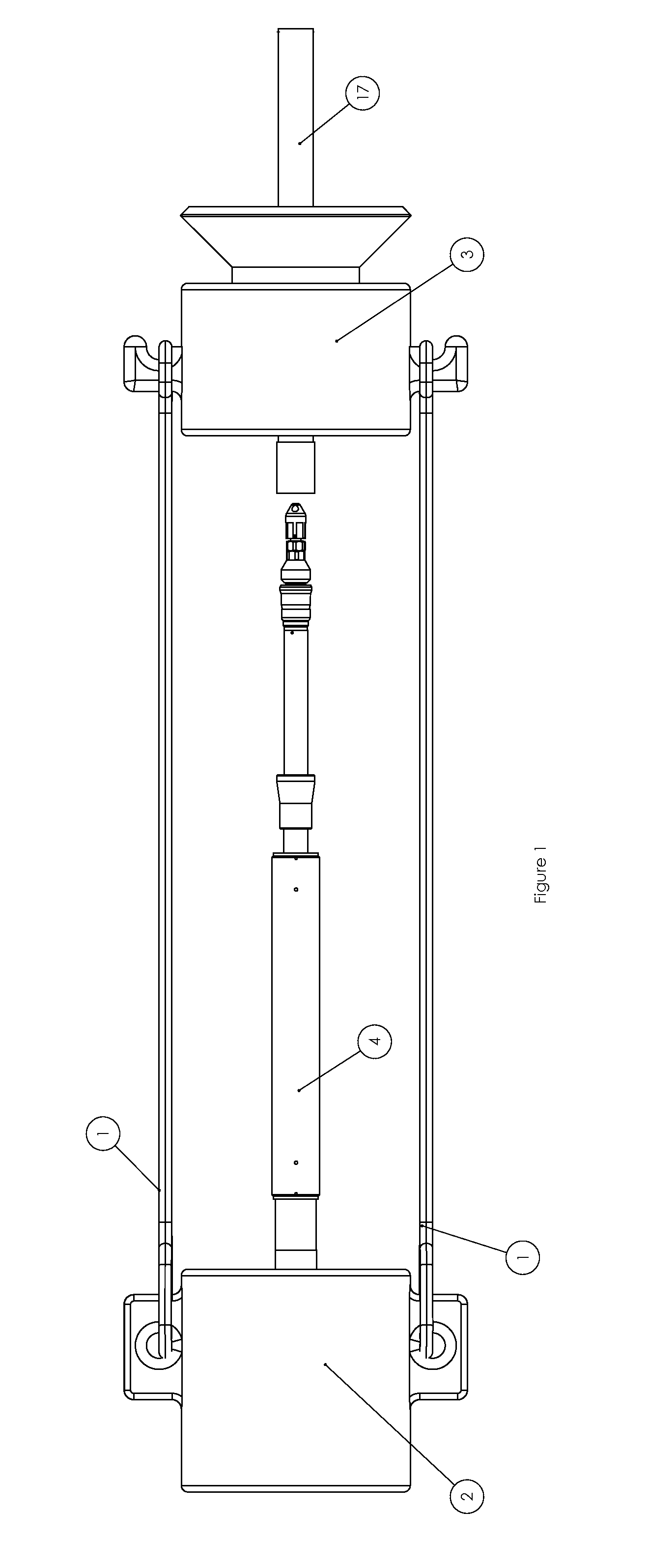

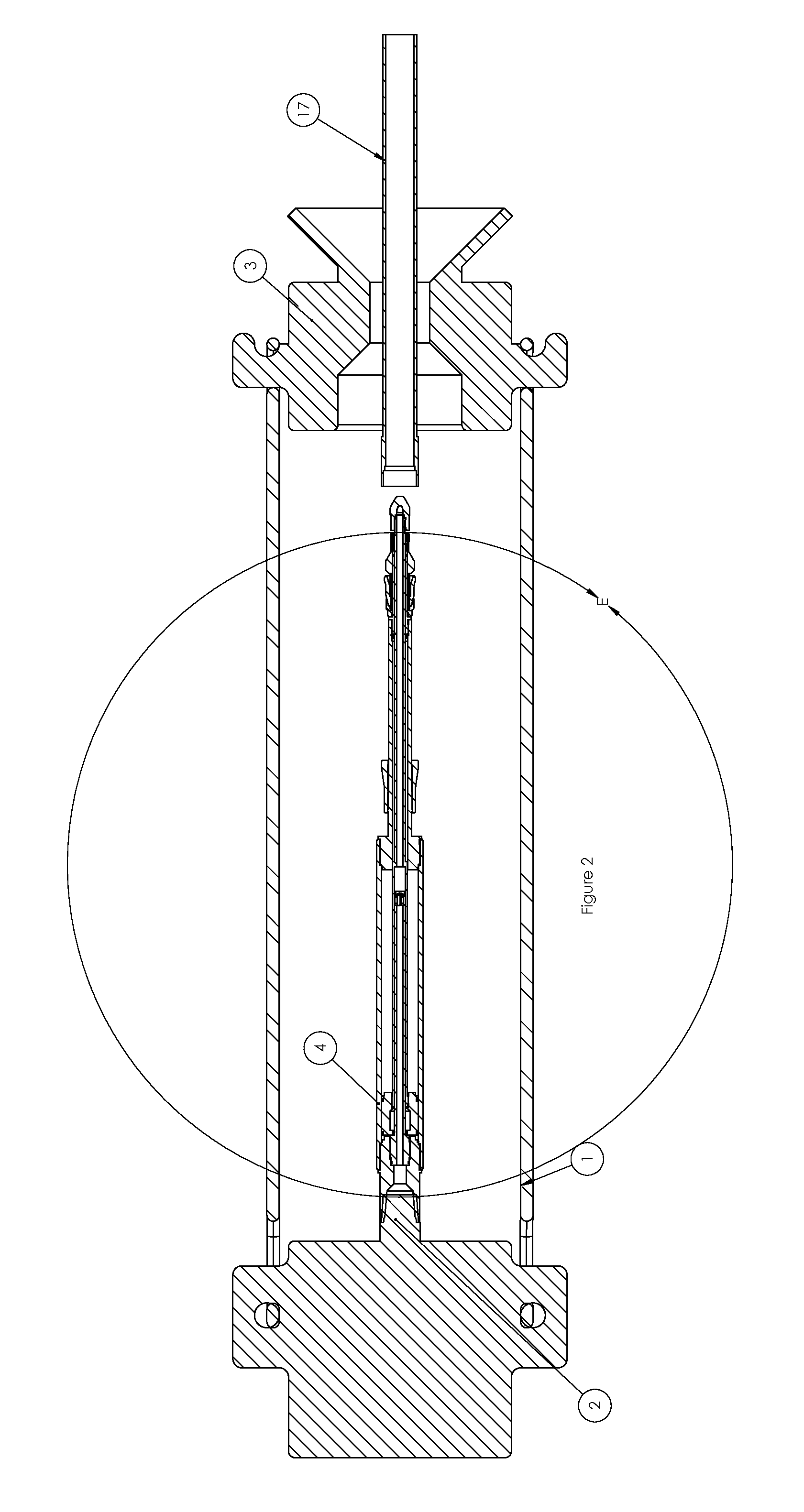

[0020]In FIG. 1 the fill up tool 4 is hanging from the top drive 2. The bails 1 hold up the elevator 3 which is also supported by top drive 2. The elevators are lowered around casing 17. This is also illustrated with FIG. 2 In this position the elevators can swing and move around without interfering with fill up tool 4 since it is positioned above the elevators.

[0021]In FIG. 3 a moveable sealed piston 5 moves inside wall 41 of fill up tool 4. Piston 5 is connected to stroke shaft 51 which is connected to nose 10. There is an upper volume 401 and lower volume 402 that can be manipulated to move piston 5 up or down. FIG. 3A is the valve in the closed position. When piston 5 is in the up position stroke shaft 51 blocks the flow of fluid from inner passage 151 attempting to pass through bore 145.

[0022]In FIG. 4 the fill up tool 4 is extended to fill up the casing 17. Flow through the tool is possible as extension starts and while extension continues to full extension stroke. Alternative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com