Anti-Scalping Transdermal Patch Packaging Film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1-5

[0092]Examples 1-4 are comparative examples (not of the invention). Example 5 is an example according to the present invention. In all of the examples, a multilayer film is provided having a base film and connected sealant film. The sealant film has a surface layer which is designed to contact the article to be packaged e.g. a transdermal patch article, and to permit heat sealing of the multilayer film to form a container such as a pouch. The EAA / LDPE / COC sealant layer of the invention and the comparative sealant layers were either extrusion coated or adhesively laminated to In all of the examples 1-5, a multilayer base film having the following structure: OPET / Primer / PE / EAA / Foil was made and only the connected sealant film was varied.

Base Film

[0093]The base film was comprised of five layers having an ordered structure of:

/ Layer 1 / Layer 2 / Layer 3 / Layer 4 / Layer 5 / corresponding to:

/ exterior layer 1 / primer layer 2 / bulk layer 3 / adhesive layer 4 / O2 layer 5 / : or more particularly,

/ OPET / PE...

example 5

Of the Invention

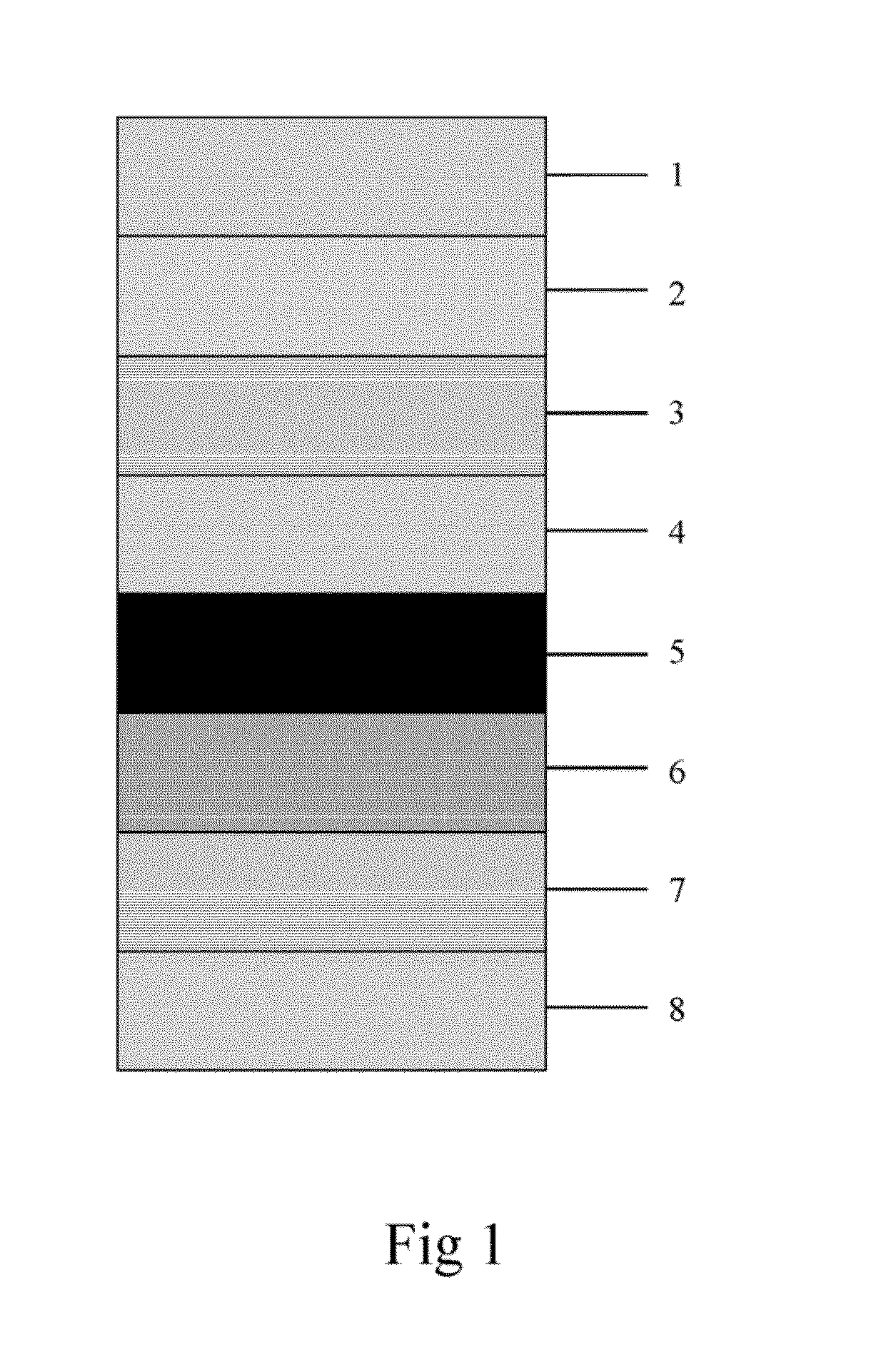

[0100]The film structure in Example 5 is exemplary of a film according to the present invention. The base film for example 5 was produced in the same manner as for comparative example 2. In this example, the sealant film was a three-layer coextrusion of EAA, LDPE and Ethylene-norbornene copolymer (COC) which was extrusion coated onto the aluminum foil surface of the multilayer base film to produce an eight layer film having the structure: 0.92 mil OPET / primer / 0.42 mil LDPE / 0.1 mil EAA / 0.35 mil foil / 0.17 mil EAA / 0.65 mil LDPE / 0.43 mil COC and a total thickness of 3.0 mils (76 microns). The inventive film is well suited to package articles for collecting or administering a physiologically active substance such as transdermal drug delivery patches, or oral dissolvable thin strips and has advantageous moisture barrier, oxygen barrier, and low scalping properties as discussed below. The resultant multilayer film was tested for various properties which are reported below.

S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com