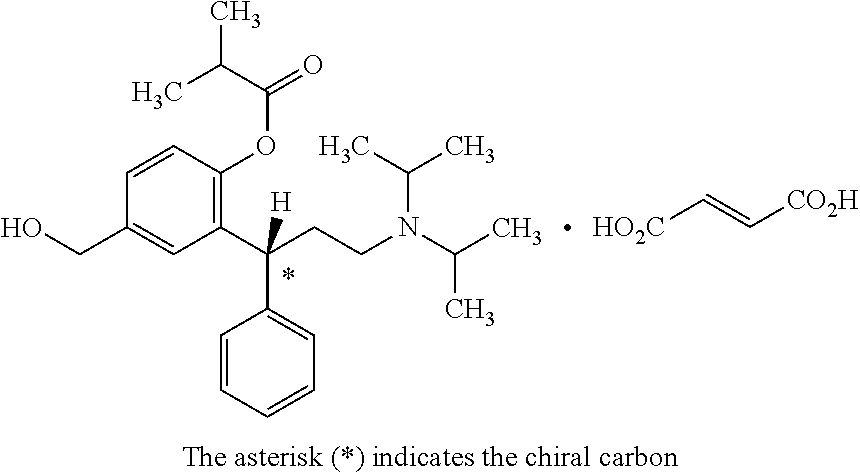

Stable compositions of fesoterodine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example-1

Pre-Lubrication of Excipients with Glyceryl Behenate

Fesoterodine Tablets Prepared According to the Composition Listed in Table 2 Using the Following Steps:

[0066]1. Pregelatinized starch, citric acid monohydrate, hydroxypropyl methylcellulose K100 CR, hydroxypropyl methylcellulose K100M CR, hydroxypropyl methylcellulose K4M, and colloidal silicon dioxide were sifted with a half quantity of glyceryl behenate through a mesh #40 sieve and dry blended for 15 minutes.[0067]2. 10% blend of step 1 and fesoterodine hydrogen fumarate were sifted together through a mesh #40 sieve.[0068]3. sifted materials of step 1 and step 2 were blended for 10 minutes.[0069]4. remaining half quantity of glyceryl behenate was sifted through a mesh #60 sieve.[0070]5. blend of step 3 was lubricated with glyceryl behenate of step 4.[0071]6. lubricated blend of step 5 was directly compressed into tablets.[0072]7. tablets of step 6 were film coated using an Opadry® dispersion.

TABLE 2Fesoterodine tablet composition...

example 3-5

[0077]

TABLE 4Fesoterodine tablet compositions prepared by granulation process:Example-3Example-4Example-5mg / Tabletmg / Tabletmg / Tablet(Dry (Wet(WetIngredientsgranulation)granulation)granulation)Intra-granular ingredientsFesoterodine fumarate8.008.008.00Pregelatinized starch147.44147.44147.44Hydroxypropyl72.0072.0072.00methylcelluloseK100 CRHydroxypropyl48.0048.0048.00methylcelluloseK100M CRHydroxypropyl24.0024.0024.00methylcelluloseK4MCitric acid0.660.660.66monohydrateColloidal9.909.909.90silicon dioxideGlyceryl behenate5.005.005.00GranulationPurified water—q.s.—Isopropyl alcohol——q.s.ExtragranularingredientsGlyceryl behenate5.005.005.00Core tablet weight320.0320.0320.0Film coatingOpadry ® blue10.0010.0010.00Film coated tablet weight330.00330.00330.00

Manufacturing Process for Example 3-5:

[0078]1. Pregelatinized starch, citric acid monohydrate, hydroxypropyl methylcellulose K100 CR, hydroxypropyl methylcellulose K100M CR, hydroxypropyl methylcellulose K4M and colloidal silicon dioxide ...

example 6

Fesoterodine Tablet Compositions Prepared by Direct Compression Process

[0082]

Ingredientmg / TabletFesoterodine fumarate8.00Pregelatinized starch116.10Hydroxypropyl72.00methylcellulose K 100 CRHydroxypropyl48.00methylcellulose K 100M CRHydroxypropyl24.00methylcellulose K 4M CRHydroxypropyl cellulose32.00Colloidal silicon dioxide9.90Glyceryl behenate10.00Core tablet weight320.00Film coatingOpadry ® blue10.00Coated tablet weight330.00

Manufacturing Process:

[0083]1. Pregelatinized starch, hydroxypropyl methylcellulose K 100 CR, hydroxypropyl methylcellulose K 100M CR, hydroxypropyl methylcellulose K4M CR, hydroxypropyl cellulose, colloidal silicon dioxide were sifted with a half quantity of glyceryl behenate through a mesh #40 sieve and blended for 15 minutes.

2. 10% of the blend of step 1 and fesoterodine fumarate were sifted together through a mesh #40 sieve.

3. sifted materials of step 1 and 2 were blended for 10 minutes.

4. remaining half quantity of glyceryl behenate was sifted through a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com