Cold storage heat exchanger

a heat exchanger and cold storage technology, applied in indirect heat exchangers, domestic cooling devices, lighting and heating devices, etc., can solve the problems of affecting the comfort of the vehicle interior, affecting the efficiency of fuel consumption, and limiting the temperature change of blown-out air, so as to achieve high melting point and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

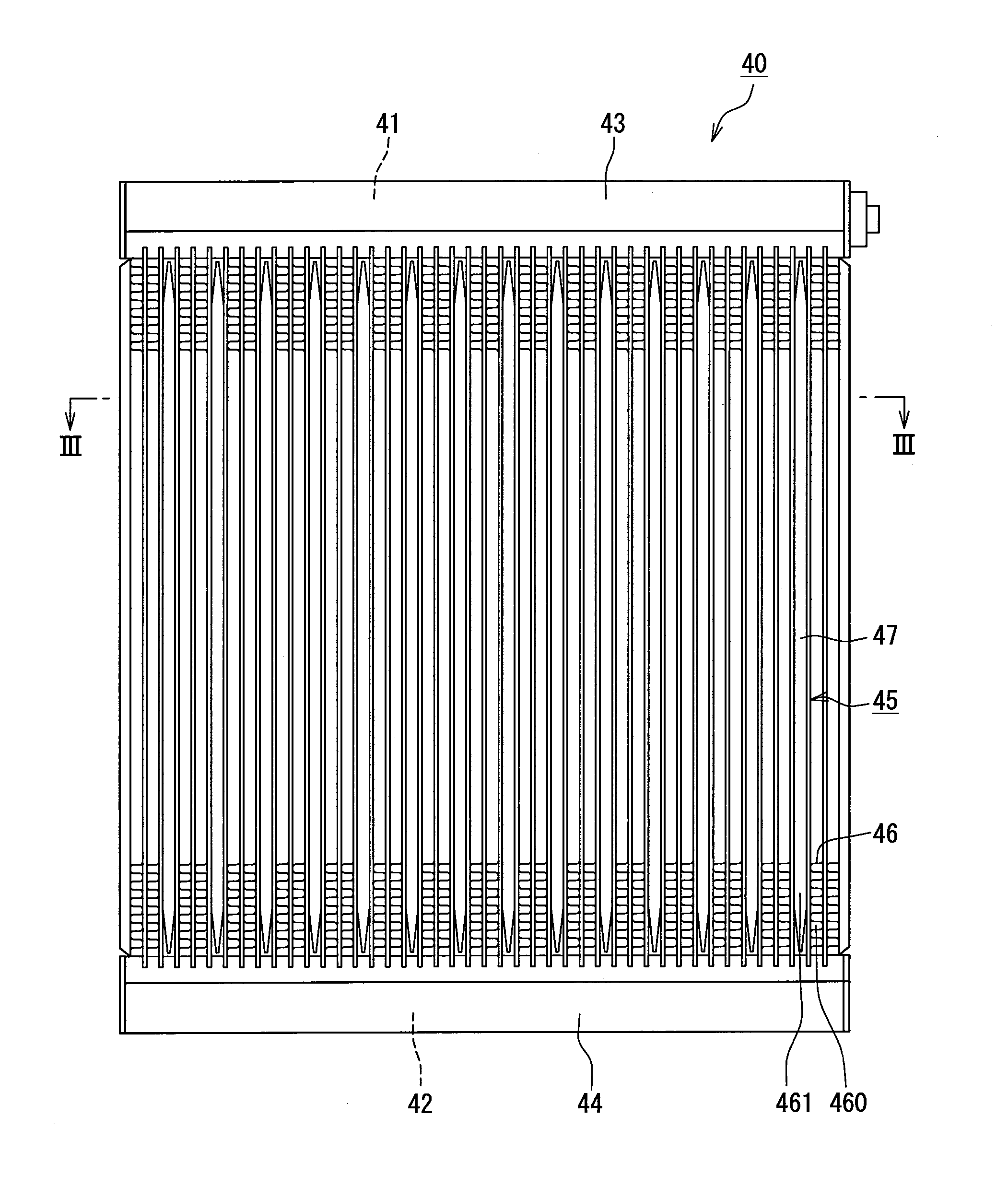

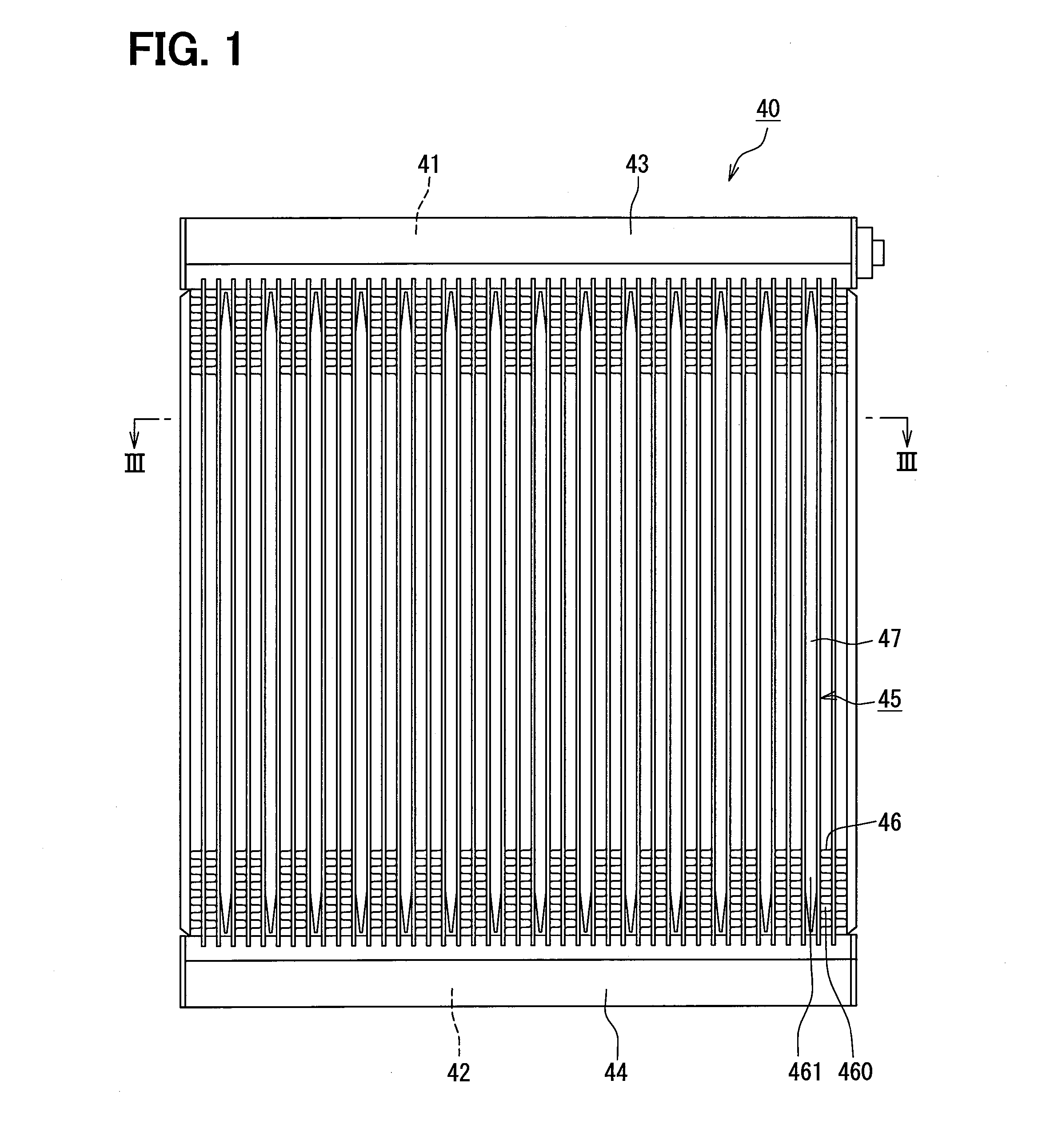

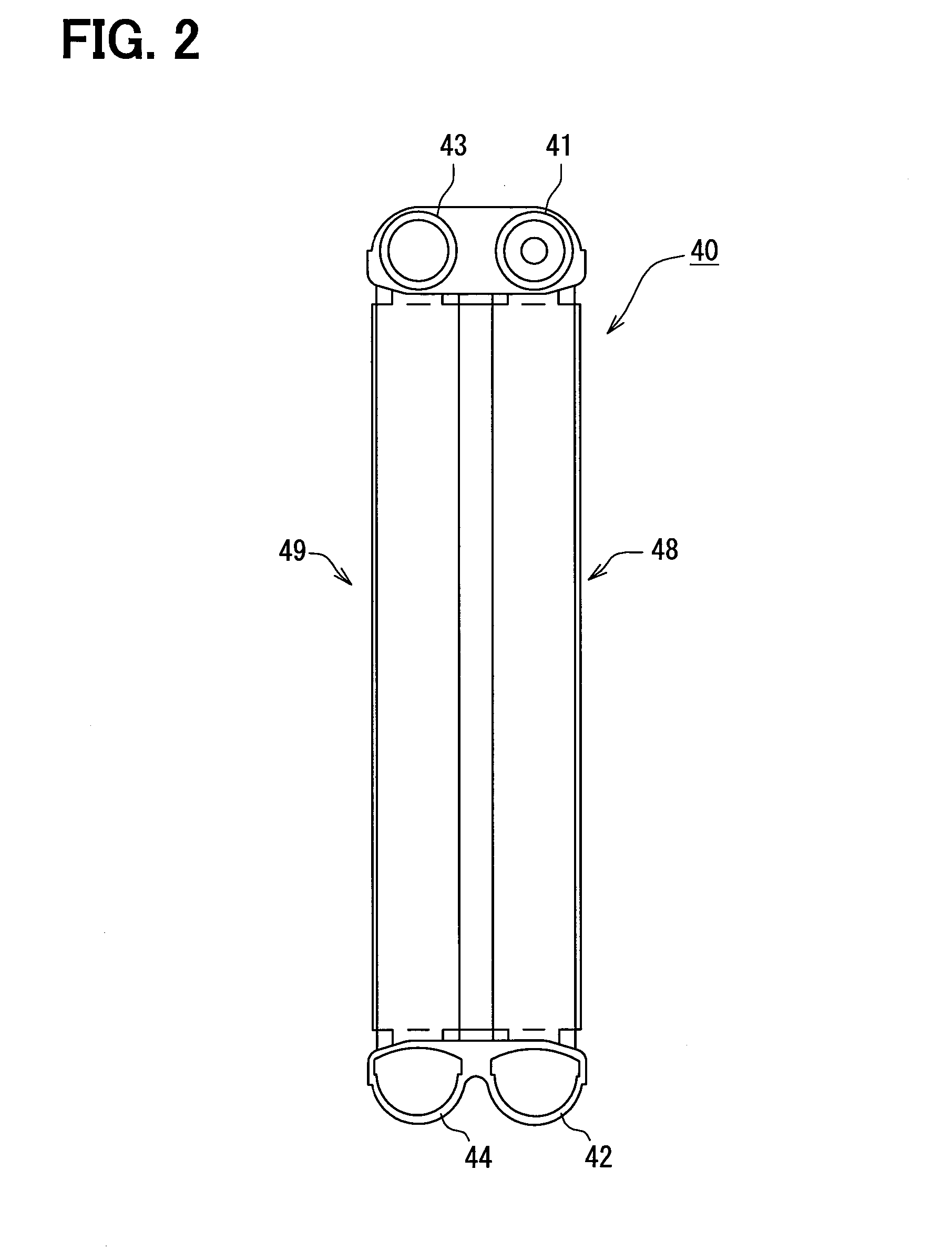

[0035]A first embodiment will be described in reference to FIGS. 1 to 5. An evaporator 40 constitutes a refrigeration cycle system (not shown). The refrigeration cycle system is used for, for example, an air-conditioning system for a vehicle. The refrigeration cycle system includes, although not shown, a compressor, a radiator, a decompressor, and the evaporator 40. These components are connected through a pipe annularly to constitute a refrigerant circulation passage. The compressor is driven by a power source for vehicle traveling. Accordingly, when the power source stops, the compressor also stops. The compressor draws in the refrigerant from the evaporator 40, compresses the refrigerant, and discharges the refrigerant into the radiator. The radiator cools high-temperature refrigerant. The radiator is also referred to as a condenser. The decompressor decompresses the refrigerant cooled by the radiator. The decompressor can be provided by a fixed throttle, a temperature type expan...

second embodiment

[0063]A second embodiment will be described in reference to FIGS. 6 and 7. The present embodiment is characterized in that cold storage cases 60A are arranged to be in contact with each other. Because of such a configuration in which the cold storage cases 60A are in contact, the space can be used more effectively. Accordingly, the amount of cold storage materials 50a, 50b, with which a cold storage container 47 can be filled, can be made large. Operation and effects of the other configuration are similar to the above-described first embodiment.

third embodiment

[0064]A third embodiment will be described in reference to FIG. 8. The present embodiment is characterized in that the inside of a cold storage container 47C is divided by a partition 70, and that cold storage materials 50a, 50b having different melting points are accommodated respectively in the divided spaces. One sealing port 61, through which the cold storage material 50a, 50b is sealed, is provided for this cold storage container 47C. Accordingly, two types of the cold storage materials 50a, 50b are sealed through the one sealing port 61. As a result, the configuration is simplified, and is easily handled as the cold storage container 47C. The sealing port 61 is provided at the outer periphery of the cold storage container 47C on an upstream side or on a downstream side in a flow direction of air, and is provided on a leeward side in the present embodiment. Because of such a configuration, the space can be used more effectively. Accordingly, the amount of the cold storage mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com