Composition, apparatus, kit and method and uses thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Continuous Gasket at the Interface Between the Skin and the Dressing Edge

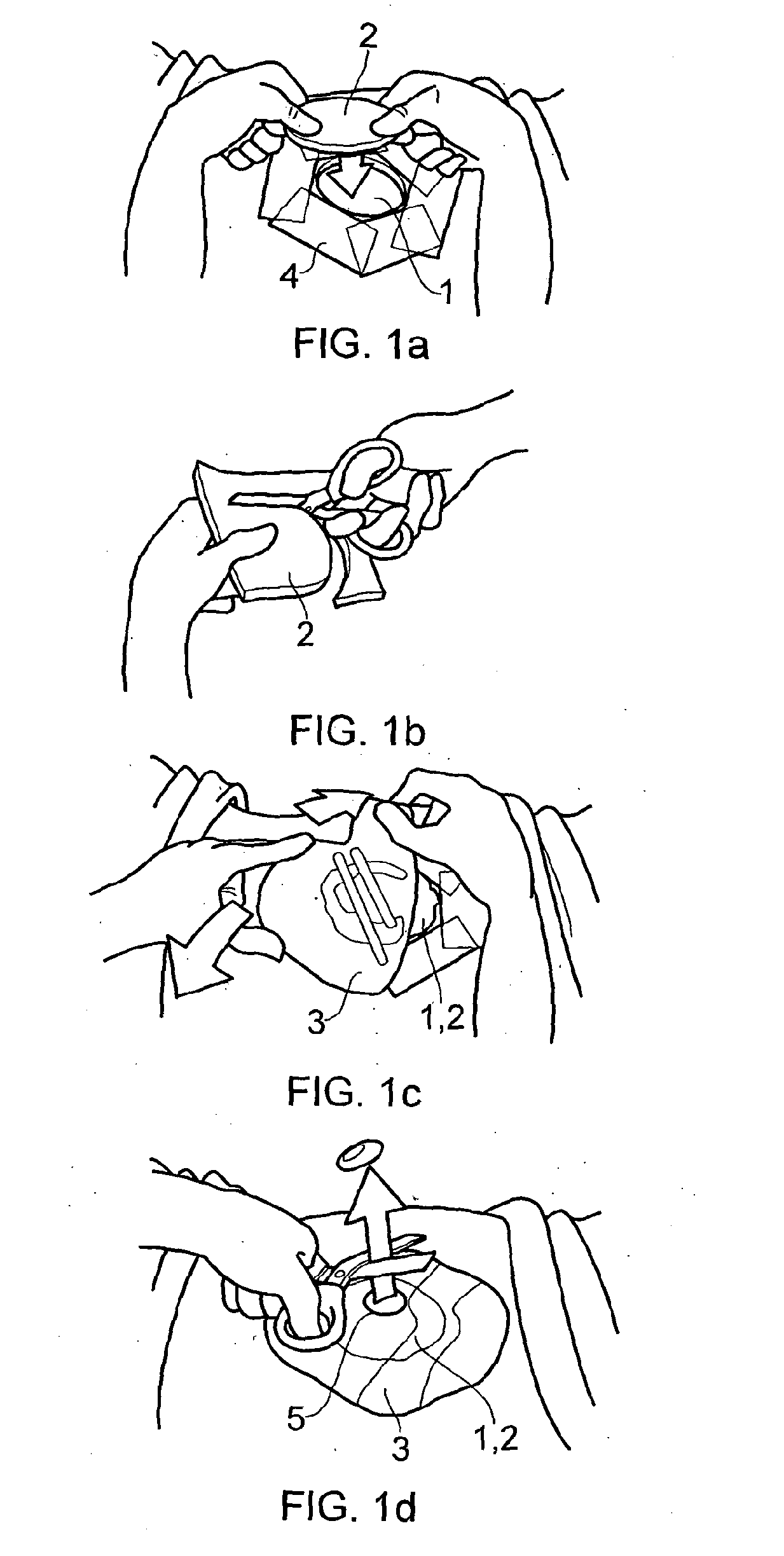

[0378]1. Prepare and clean the skin surrounding the wound area. Any excess hair should be clipped to ensure close approximation to the wound.

2. Using an appropriate dressing for the wound to be treated, as hereinbefore defined, remove the appropriate release handle(s) and anchor the adhesive side of the dressing to the skin. Smooth the dressing over the wound removing the remaining release handle(s) and ensure that the dressing is adhered all around the wound. (see Modified version of the Allevyn Gentle Border Instructions For Use http: / / global.smith-nephew.com / us / product25361—5871.htm)

3. Apply the sealant at the interface between the skin and the edge of the dressing such that the sealant forms a continuous gasket between the skin and the entire perimeter of the dressing edge.

[0379]In the case of NPWT systems the dressing should be adhered to the wound as in Step 2, negative pressure should be applied and any ...

embodiment 2

Continuous Gasket at the Interface Between the Skin and the Dressing Edge+ Retention Strips

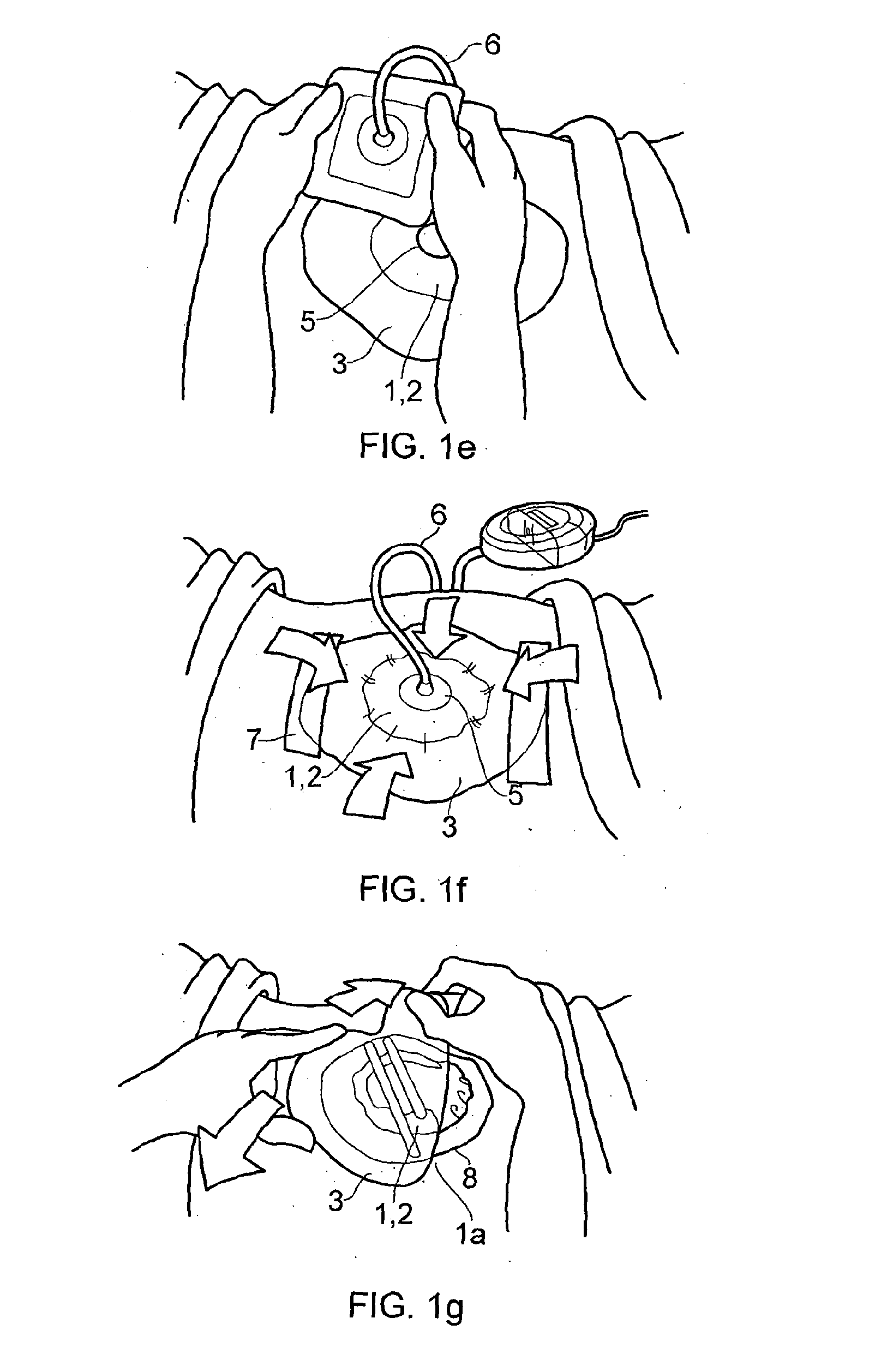

[0381]Follow Steps 1 and 2 in Embodiment 1.[0382]3. Retention strips are applied, covering the dressing borders, the sealant and the skin. If sealant is a curing system a time delay may need to be observed here.

[0383]In the case of NPWT systems the dressing should be adhered to the wound as in Step 2, negative pressure should be applied and any leaks minimised. Once air leaks have been minimised the sealant and retention strips should be applied as in Step 3,

embodiment 3

Localised Sealing at the Interface Between the Skin and the Edge of the Dressing

[0384]Follow Steps 1 and 2 in Embodiment 1.[0385]3. Examine the dressing that extends over the skin from the peri-wound area to the edge of the dressing. Identify any locations where a poor seal could be possible and that are not readily improved by smoothing the dressing down (areas that are difficult to seal, areas with complex body contours, areas where dressing materials overlap, areas with hair, sections of the dressing that have become raised, tented or rucked). Apply the sealant at these discrete points at the interface between the skin and the edge of the dressing.

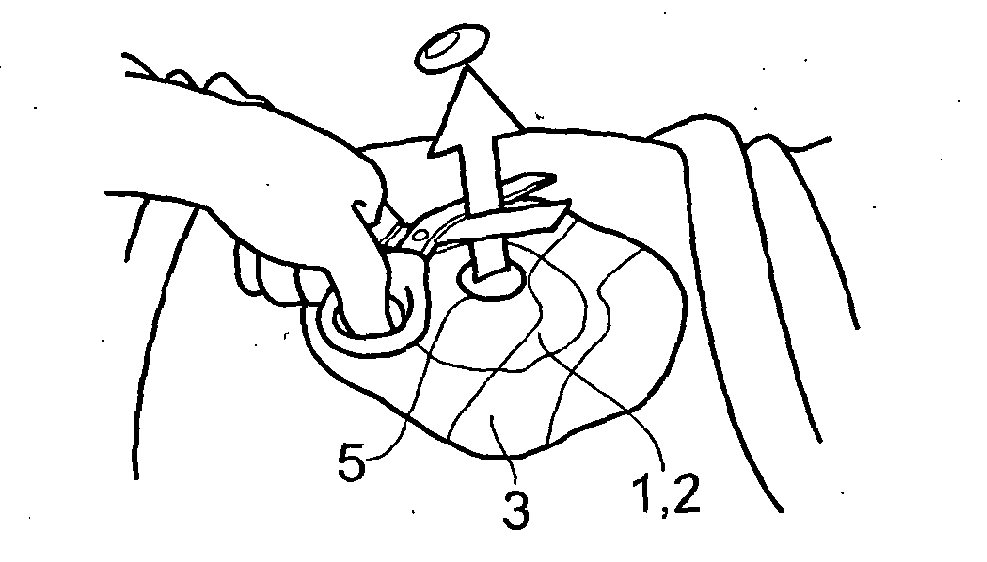

[0386]The embodiment is illustrated by example in FIG. 2g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com