Method and Machines for Transforming Initial Sealed Packagings into Irregular Cubic or Polyhedral Packagings by Means of Sealing and Cutting Flaps

a technology of sealing and cutting flaps, applied in the field of packaging, can solve the problems of not entirely volumetric, rectangular containers, less stable cubic containers, etc., and achieve the effect of greater stability, rigidity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

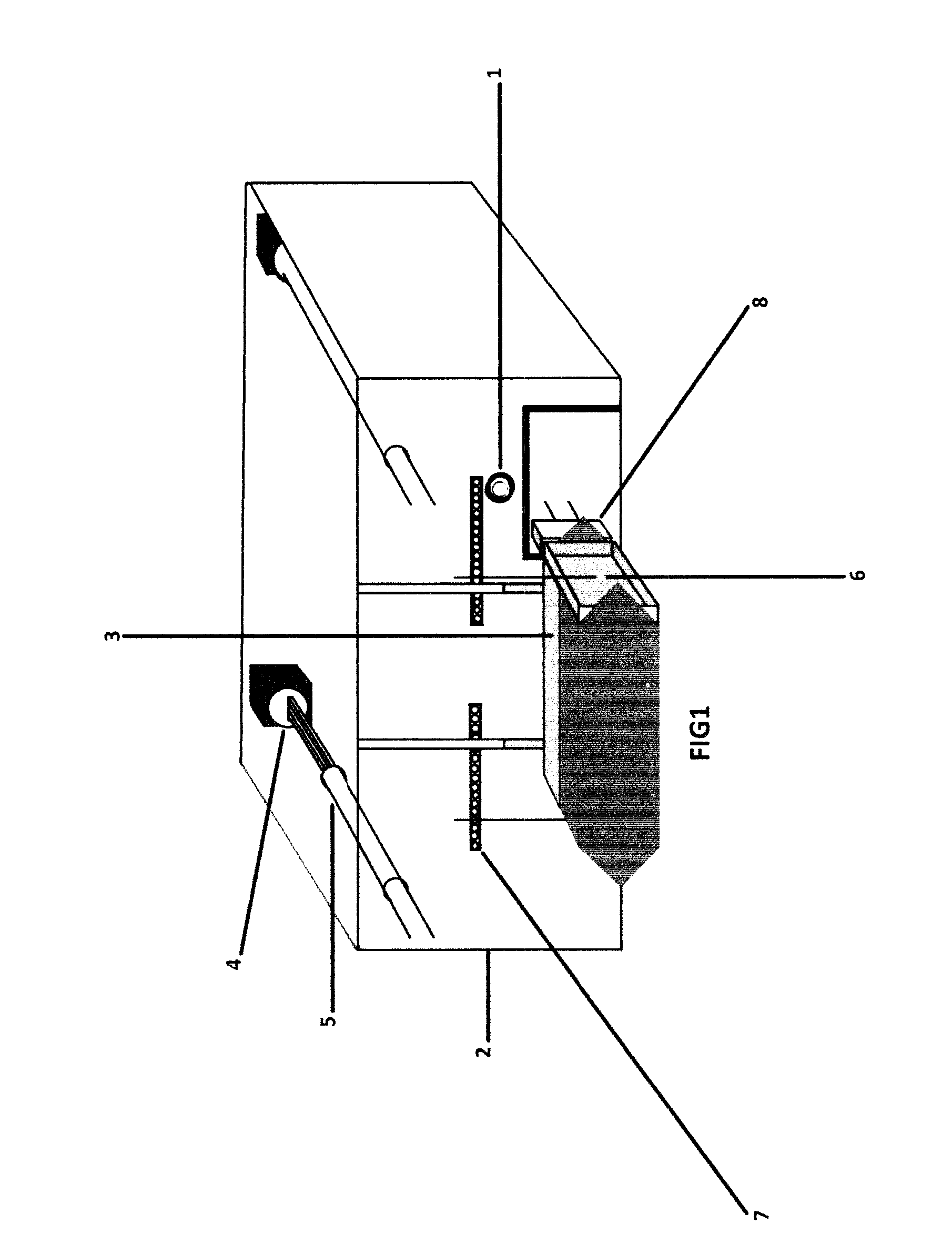

[0073]FIG. 1: shows an overall perspective of the machine model [a].

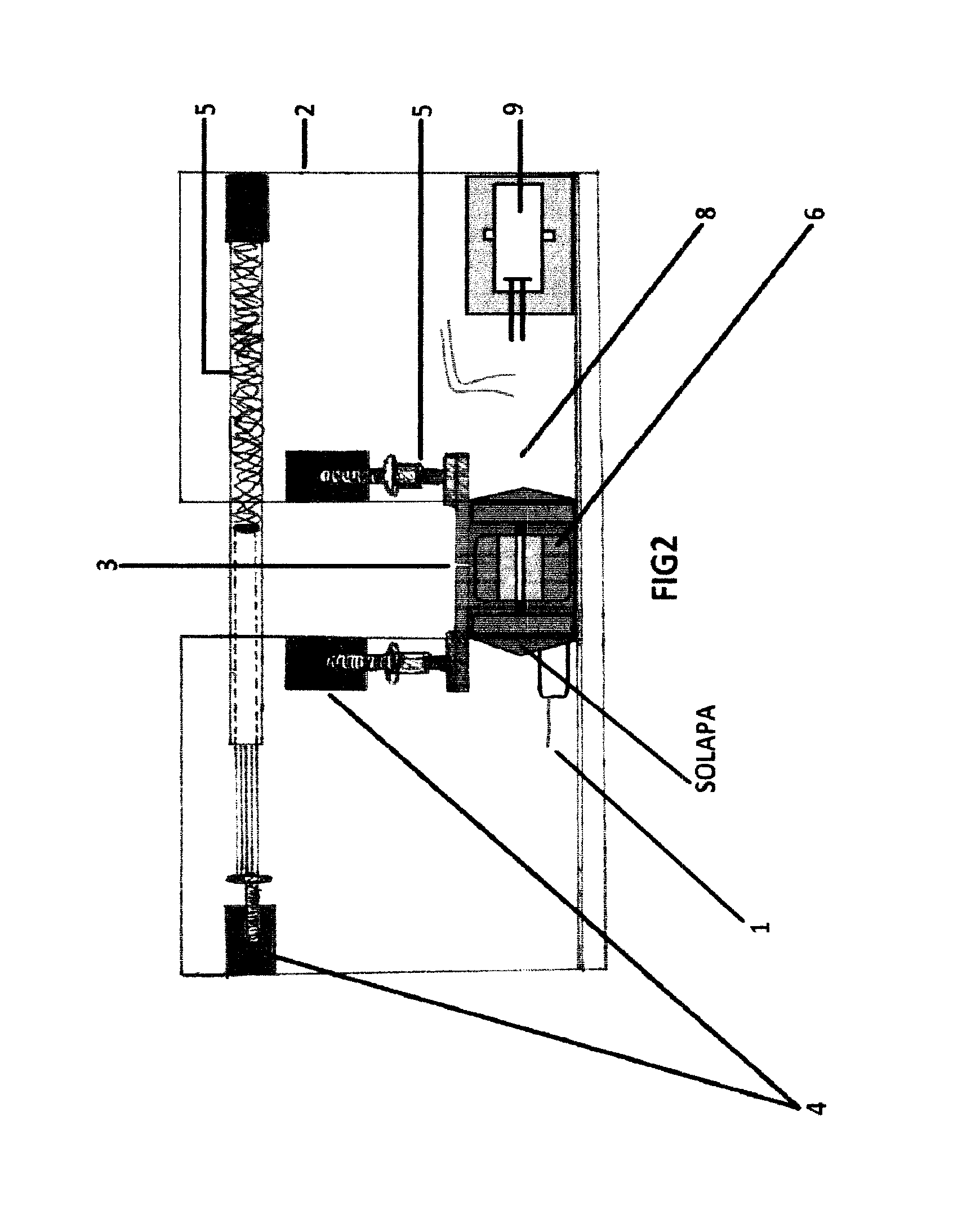

[0074]FIG. 2: shows a detailed view of the elevation of the machine model [a].

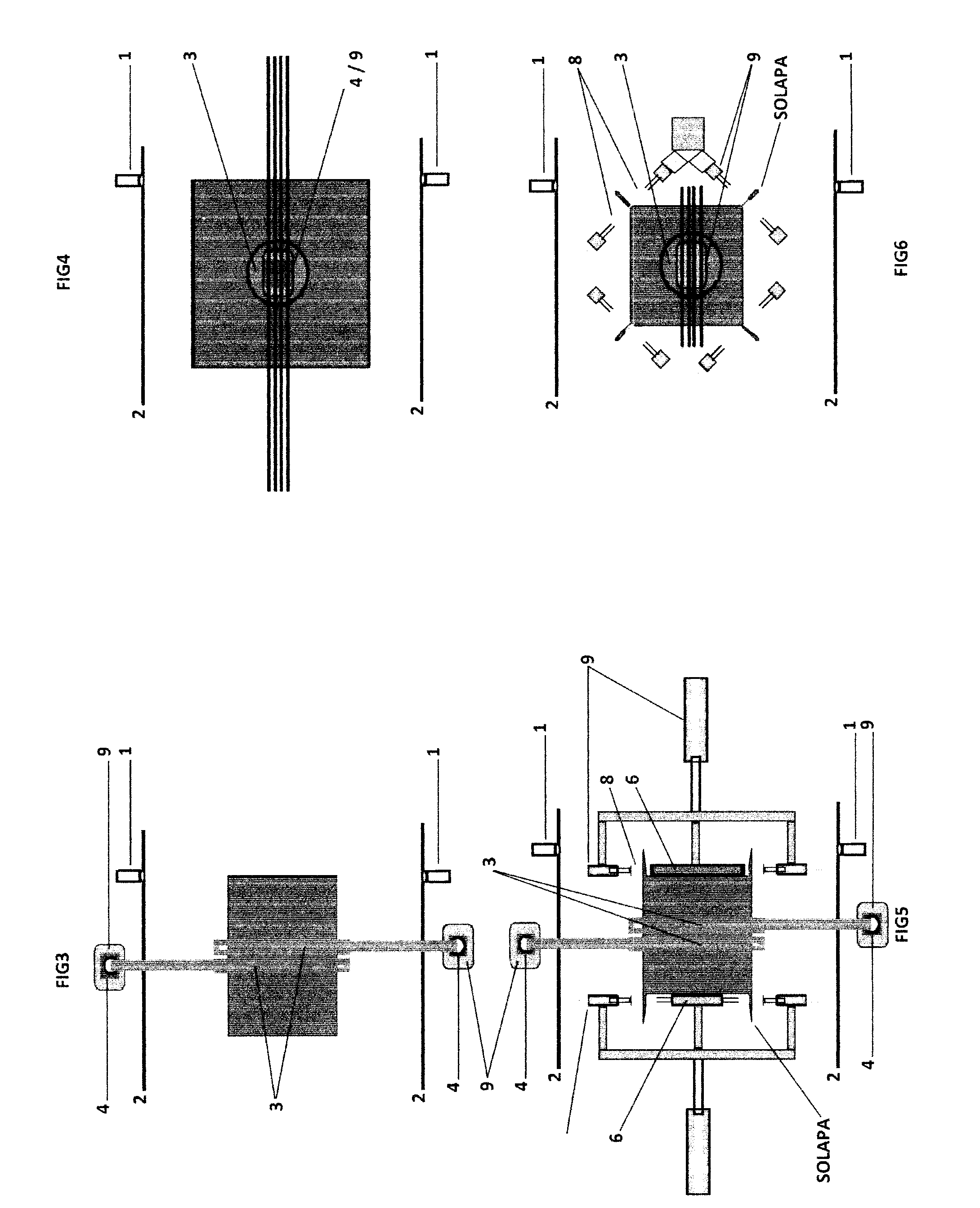

[0075]FIG. 3: shows a plan view of the container holding system with damping adjustable horizontal models [b1 / b2].

[0076]FIG. 4: shows a plan view of the clamping system with adjustable cushioning packaging in vertical models [b1 / b2].

[0077]FIG. 5: shows a plan view of the machine model cubic transformation [b1] with clamps quad / triple: sealing / cutting and impact.

[0078]FIG. 6: shows a plan view of the machine model cubic transformation [b2] with diagonal clamps sealing / cutting and impact.

[0079]FIG. 7: shows a detailed view of the elevation of the machine model [c] which is vertical, where a pack or two-sided original bag and sealed with water in its interior, is caught between the subjection clamps (3) or starting point, or baseline.

[0080]Each set of clamps triple (6,8) is attached to a rod of a pneumatic cylinder / electrical, in turn, these ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com