Inorganic polysilazane resin

a technology of organic polysilazane and resin, which is applied in the direction of silicon compounds, transportation and packaging, liquid/solution decomposition chemical coatings, etc., to achieve the effect of small residual stress and small shrinkag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0071]Three moles (303 g) of dichlorosilane having a purity of 99% or more were injected into a mixed solvent consisting of 1 kg of dehydrated pyridine and 3 kg of dibutyl ether at −30° C. under stirring. While maintaining the temperature of the solution at −30° C., 2 moles (34 g) of ammonia gas having a purity of 99.9% or more were injected into the mixture under stirring. The mixture was reacted for 2 hours while maintaining the temperature at −30° C. to obtain a solution of silazane oligomer containing unreacted Si—Cl. The existence of the unreacted Si—Cl was confirmed by using FTIR, VIR-9450 manufactured by JASCO Corporation.

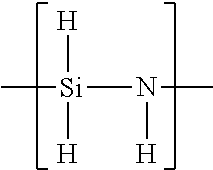

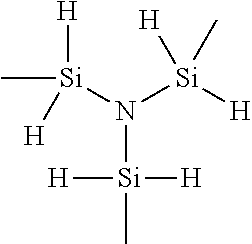

[0072]The oligomer obtained contains following compounds and the like, and the total number of NH and the total number of Cl in the oligomer are the same.

[0073]In the oligomer formation process, HCl was generated but most of it was reacted immediately with excessive pyridine to form pyridine hydrochloride and the pyridine hydrochloride formed was precipitate...

example 2

[0075]A silazane oligomer solution containing unreacted Si—Cl was prepared by the same process as Example 1. To the silazane oligomer solution obtained, 2 moles (204 g) of N,N,N′,N′-tetramethyldiaminomethane were added and this reaction system was heated gradually to 80° C. under stirring and held at this temperature for one hour, followed by cooling down gradually to the room temperature. Subsequently, 1 mole (17 g) of ammonia gas having a purity of 99.9% was injected again to the mixture under stirring and then the mixture was allowed to stand for 30 minutes. The obtained slurry reaction mixture was filtered with a glass filter to remove pyridine hydrochloride to obtain a filtrate. To the filtrate obtained, dibutyl ether was added and then heated to 50° C., followed by distillation under the reduced pressure of 20 mmHg to remove pyridine at this temperature. Through these processes, Solution B having a concentration of 20% by weight, which contains a resin (Resin B) having a weigh...

example 3

[0076]Three moles (303 g) of dichlorosilane having a purity of 99% or more were injected into a mixed solvent consisting of 300 g of dehydrated pyridine and 3 kg of dibutyl ether under stirring at 0° C. While maintaining the temperature of the solution at 0° C., 3 moles (51 g) of ammonia gas were injected into the mixture under stirring. The mixture was reacted for 2 hours under stirring while maintaining the temperature at 0° C. to obtain a solution of polysilazane polymer. It was confirmed by FTIR, VIR-9450 manufactured by JASCO Corporation that the polymer does not contain the unreacted Si—Cl. The molecular weight of the polymer was 2,300. Pyridine hydrochloride and ammonium chloride, which were formed in the synthesis process of the polysilazane polymer, were removed by filtration with a centrifugal separation filter.

[0077]Subsequently, 1 mole (107 g) of 2,6-lutidine was added to the filtrate and then the reaction system was heated gradually to 90° C., followed by injecting 1 mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shrinkage | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com