Pure metal and ceramic nanofibers

a technology of ceramic nanofibers and metals, applied in the direction of zirconium oxides, copper oxides/halides, conductive materials, etc., can solve the problems of poor coherence, low performance, unsuitability for many applications, etc., and achieve low cost, flexible control, and low voids and/or defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparing a Fluid Stock of Nickel Acetate and PVA

[0375]Two (2) grams of nickel acetate, the metal precursor, was dissolved in 20 ml of 1 molar acetic acid solution. The solution was stirred for 2 hours to create a solution of nickel acetate. The solution was homogenous.

[0376]In a second solution, 1 gram of 99.7% hydrolyzed polyvinyl alcohol (PVA) with an average molecular weight of 79 kDa and polydispersity index of 1.5 was dissolved in 10 ml of de-ionized water. The polymer solution was heated to a temperature of 95° C. and stirred for 2 hours to create a homogenous solution.

[0377]The nickel acetate solution was then combined with the PVA solution to create a fluid stock. In order to distribute the precursor substantially evenly in the fluid stock, the precursor solution was added gradually to the polymer solution while being continuously vigorously stirred for 2 hours. The mass ratio of precursor to polymer for the fluid feed (based on initial nickel acetate mass) was 2:1.

example 2

Characterization of a Fluid Stock of Nickel Acetate and PVA

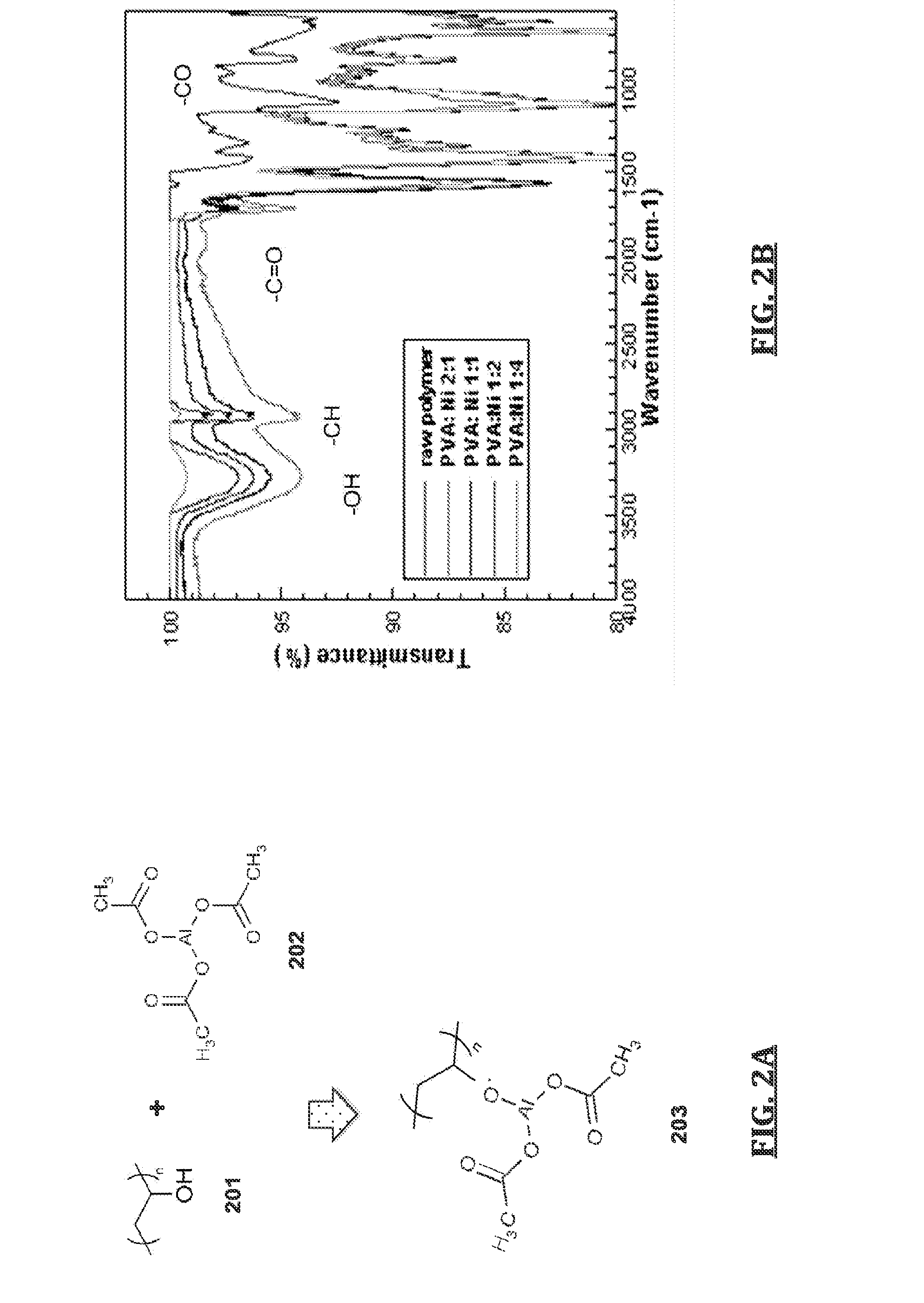

[0378]The chemical interaction between the ligand of the metal precursor and the functional group in the polymer backbone resulted in extremely high loading of metal precursors without losing the spinnability. The interaction was demonstrated in the FT-IR study for nanofibers with various ratios of PVA to Ni precursor. As demonstrated in FIG. 2, the drastic reduction of —OH bond and substantial increase in —CO bond were observed at high loading of Ni precursor (Ni:PVA=4:1).

example 3

Electrospinning a Fluid Stock of Nickel Acetate and PVA

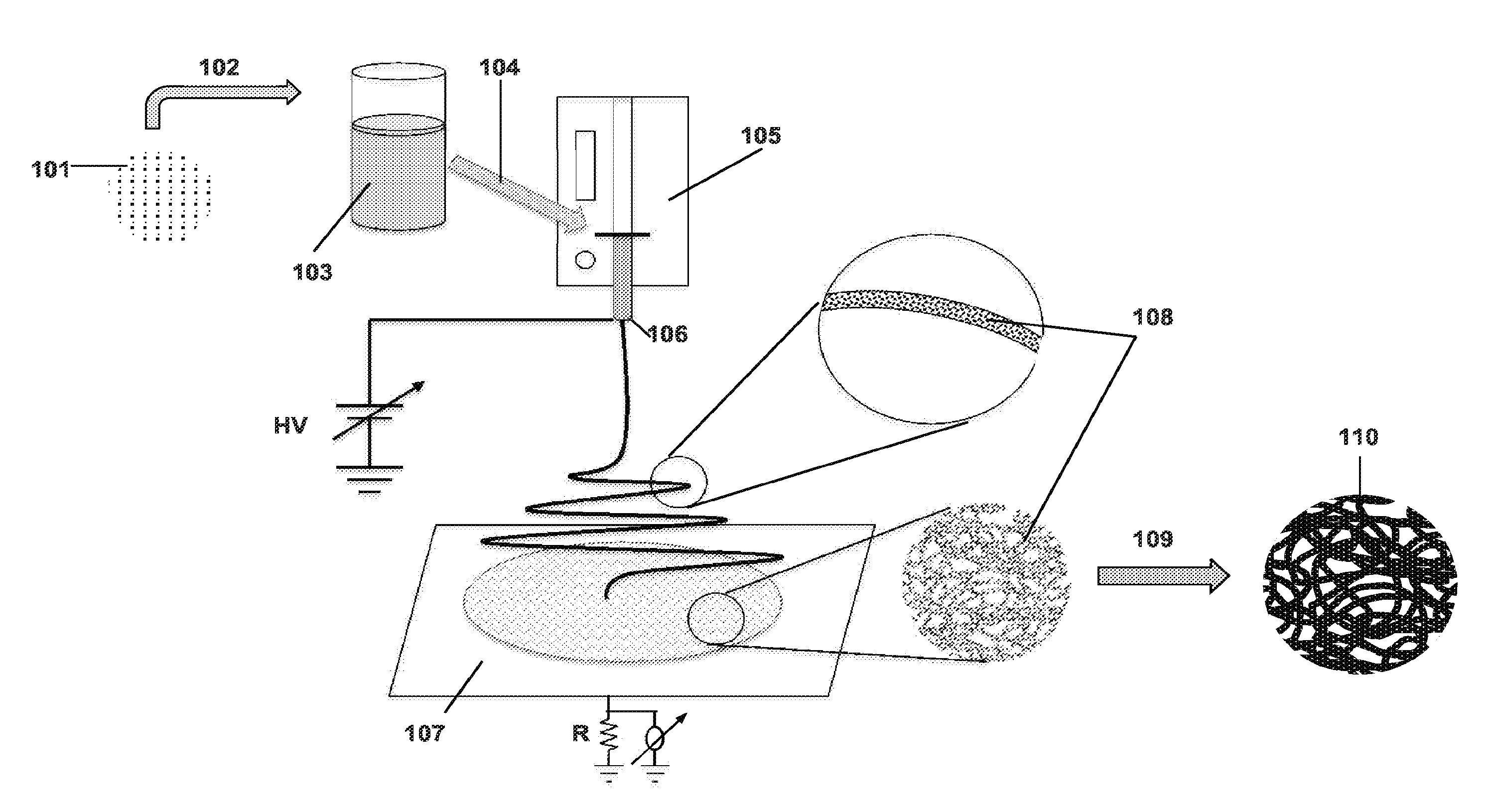

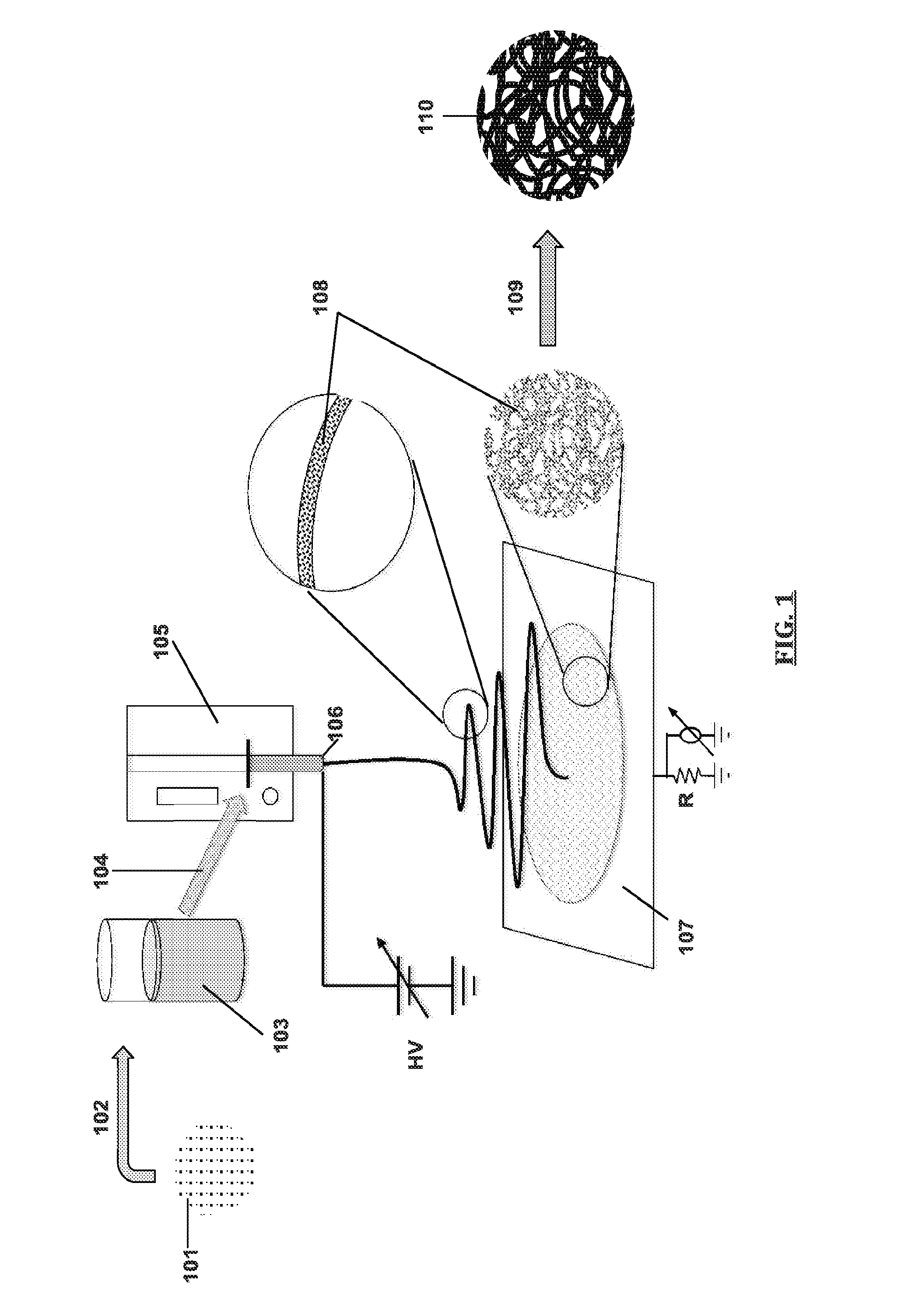

[0379]The fluid stock of Example 1 was electrospun by a gas-assisted technique. The overall process and apparatus is depicted in FIG. 1. The fluid stock was loaded into a syringe pump connected to a spinneret with an inner nozzle diameter (fluid stock) of 4.13×10−4 m and an outer (air) diameter of 1.194×10−3 m. The distance between the nozzle and the collection plate was kept at about 15 cm and the fluid stock was spun at a rate of 0.1 ml / min. A charge of +15 kV was maintained at the collector. The air velocity at the nozzle was 100 m / s. The temperature of the air and fluid stock at the nozzle was 300 K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Molar density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com