Method And Device For Determining An Operating Parameter Of A Fluid Insulated Electrical Apparatus

a technology of fluid insulated electrical apparatus and operating parameter, which is applied in the direction of instruments, air-break switches, and testing dielectric strength, etc., can solve the problems of not determining the dielectric breakdown strength e/sub>bd or an e/sub>bd, and the dielectric gas cannot allow the passage of electrical current, etc., to achieve suitable mixing ratio, reduce the gaseous amount of the condensed component, and improve the effect of insulation performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

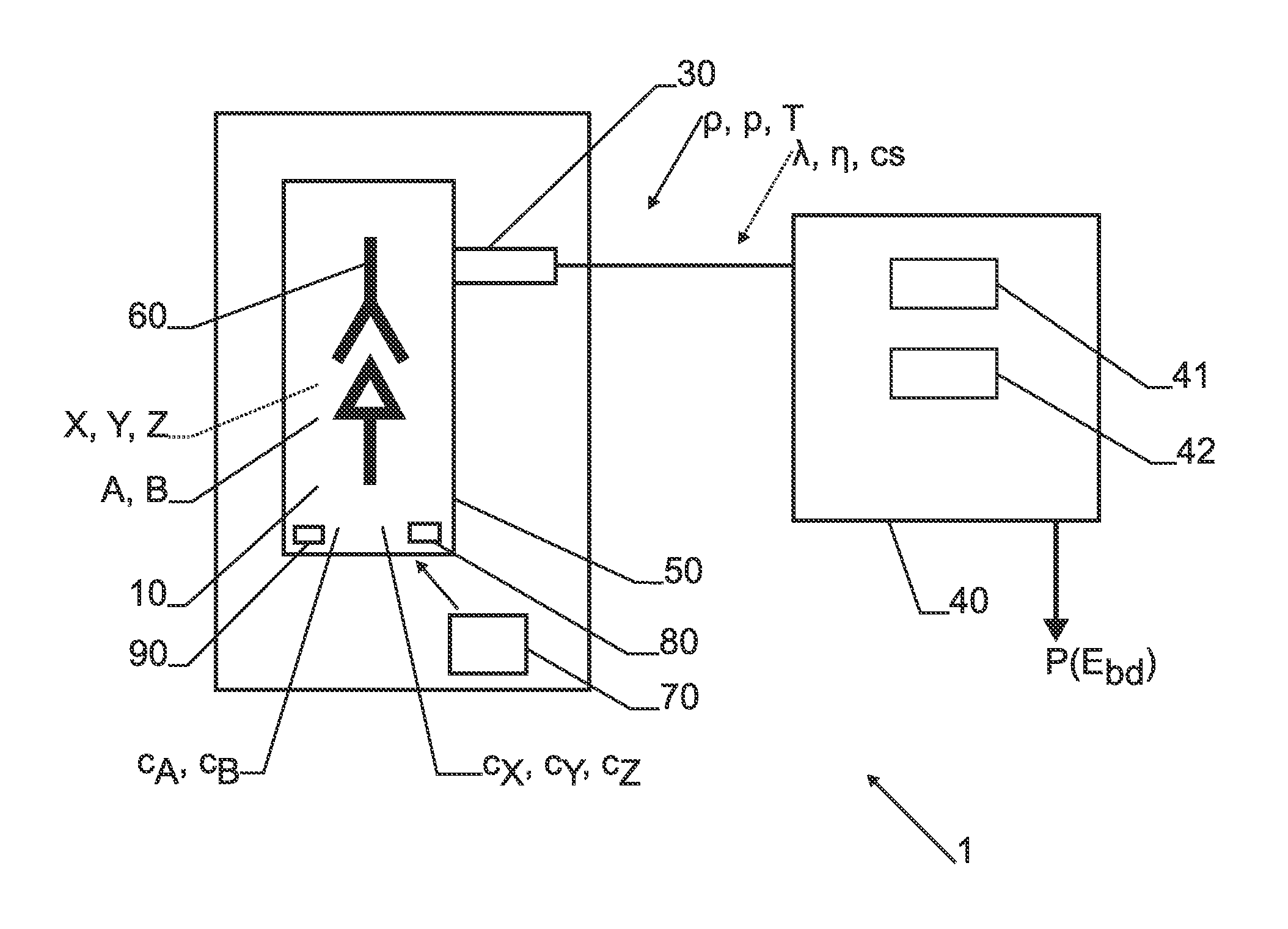

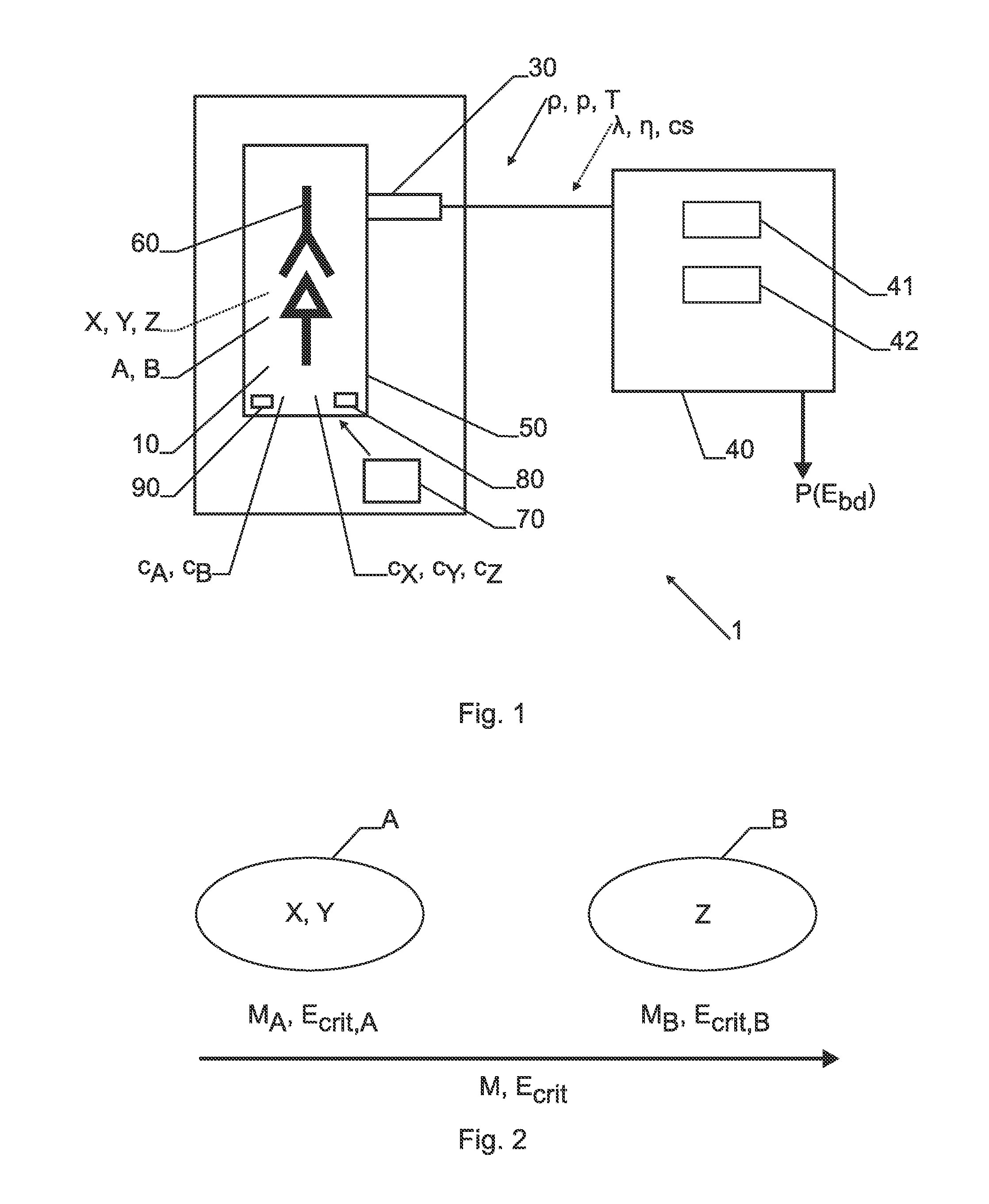

[0101]FIG. 1 shows a schematic of a fluid-insulated electrical apparatus 1, i.e. here a gas insulated switch 1. An electrically active part 60 of the fluid-insulated apparatus 1 is arranged in a gas-tight compartment 50 which encloses an insulation fluid 10 for preventing the passage of electrical current from the electrically active part 60 to the compartment 50. The insulation fluid 10 is an insulation gas 10 comprising the component X which is nitrogen N2 with a partial pressure pX=p(N2)=5.29 bar, the component Y which is oxygen O2 with a partial pressure pY=p(O2)=1.41 bar and the component Z which is “perfluoroketone C5” (see definition below) with a partial pressure pZ=p(C5)=0.3 bar at a temperature of 20° C. The total filling pressure p=pX+pY+pZ at filling time is p=pX+pY+pZ=7 bar, the total volume of the gas-tight compartment 50 (filling volume of the insulation gas 10) is V=2 m3. As an option, additionally or as replacement for component Z, a component “perfluoroketone C6” w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com