Method and apparatus for control of a plasma for spectrometry

a technology of plasma and control signal, applied in the direction of mass spectrometer, particle separator tube, spectrum investigation, etc., can solve the problems of affecting the control of the plasma, slow response to changes in conditions, and possible spectral interference, so as to facilitate stable and precise feedback control, accurate method of controlling temperature, and the effect of more precise control signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

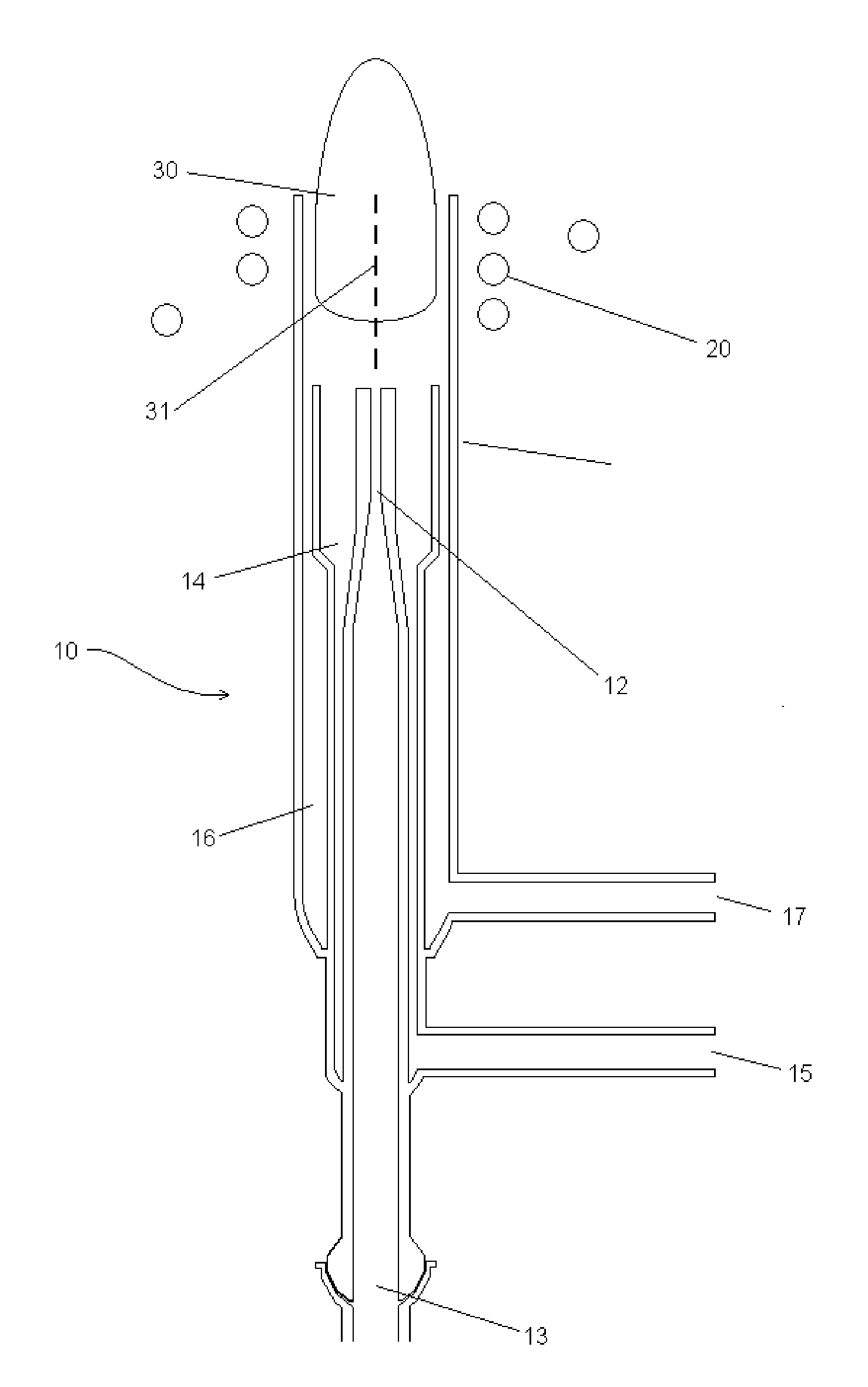

[0034]FIG. 1 is a schematic cross sectional diagram of a prior art torch and RF coil for an inductively coupled plasma for optical emission spectrometry or for mass spectrometry. Torch 10 comprises injector tube 12, auxiliary tube 14 and outer tube 16. Typically torch 10 is made of quartz glass or ceramic elements. The gas flow entering injector tube 12 at inlet 13 is known as an injection gas. Additional gas is supplied to auxiliary tube 14 via inlet 15, and this gas flow is known as auxiliary gas. A further gas flow is supplied to outer tube 16 via inlet 17, and this gas flow is known as the cool gas, as it is predominantly used to introduce a barrier of gas along the inside surface of outer tube 16. All three gases typically comprise argon. ICP coil 20 is used to couple RF power (typically, at 27 MHz) into a plasma 30 formed within and emerging from outer tube 16. Droplets or solid particles entering the inlet of torch 10 via injector tube 12 are transported in the injector gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com