Reactor for preparing precursor of lithium composite transition metal oxide and method for preparing precursor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

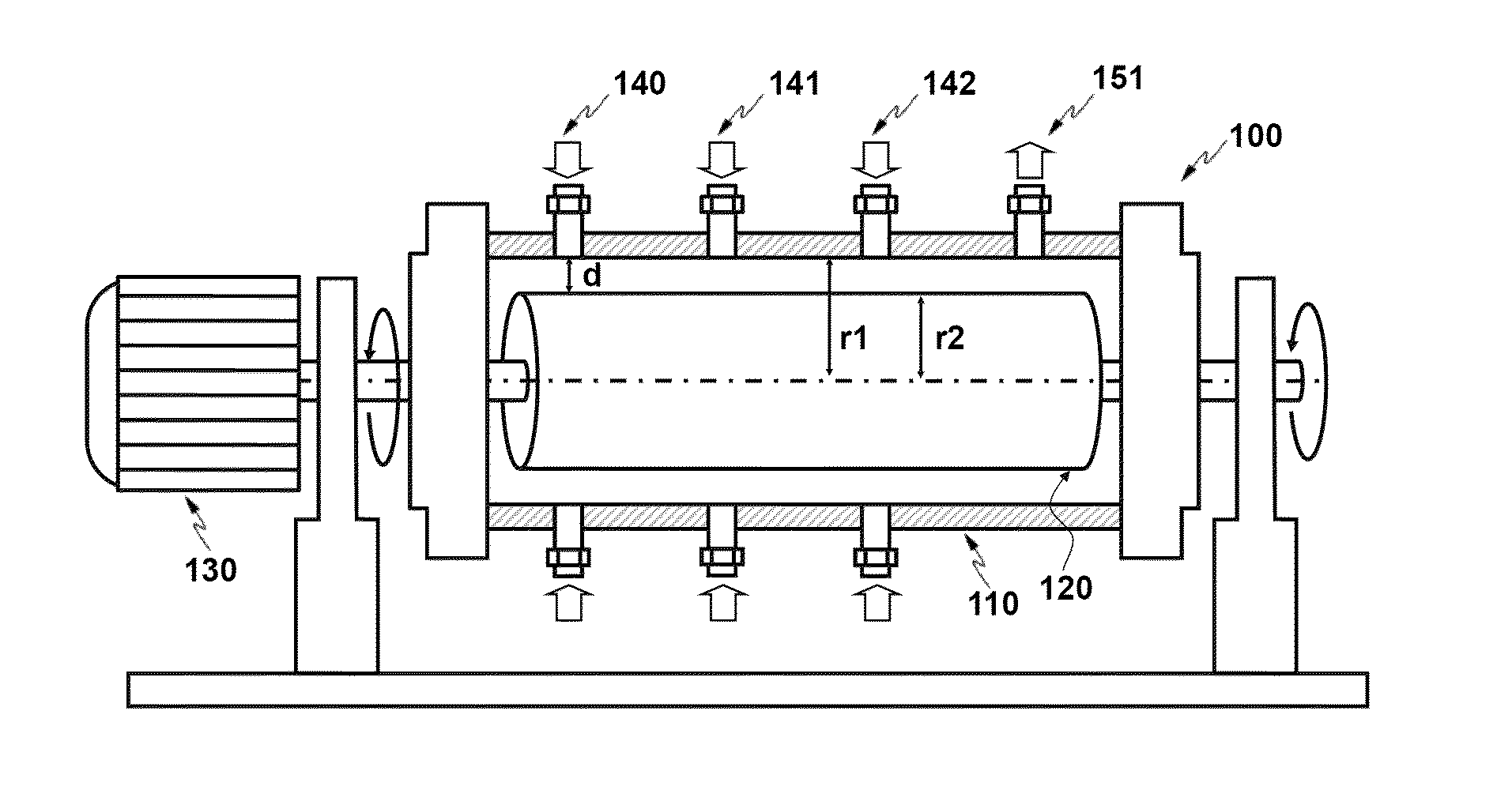

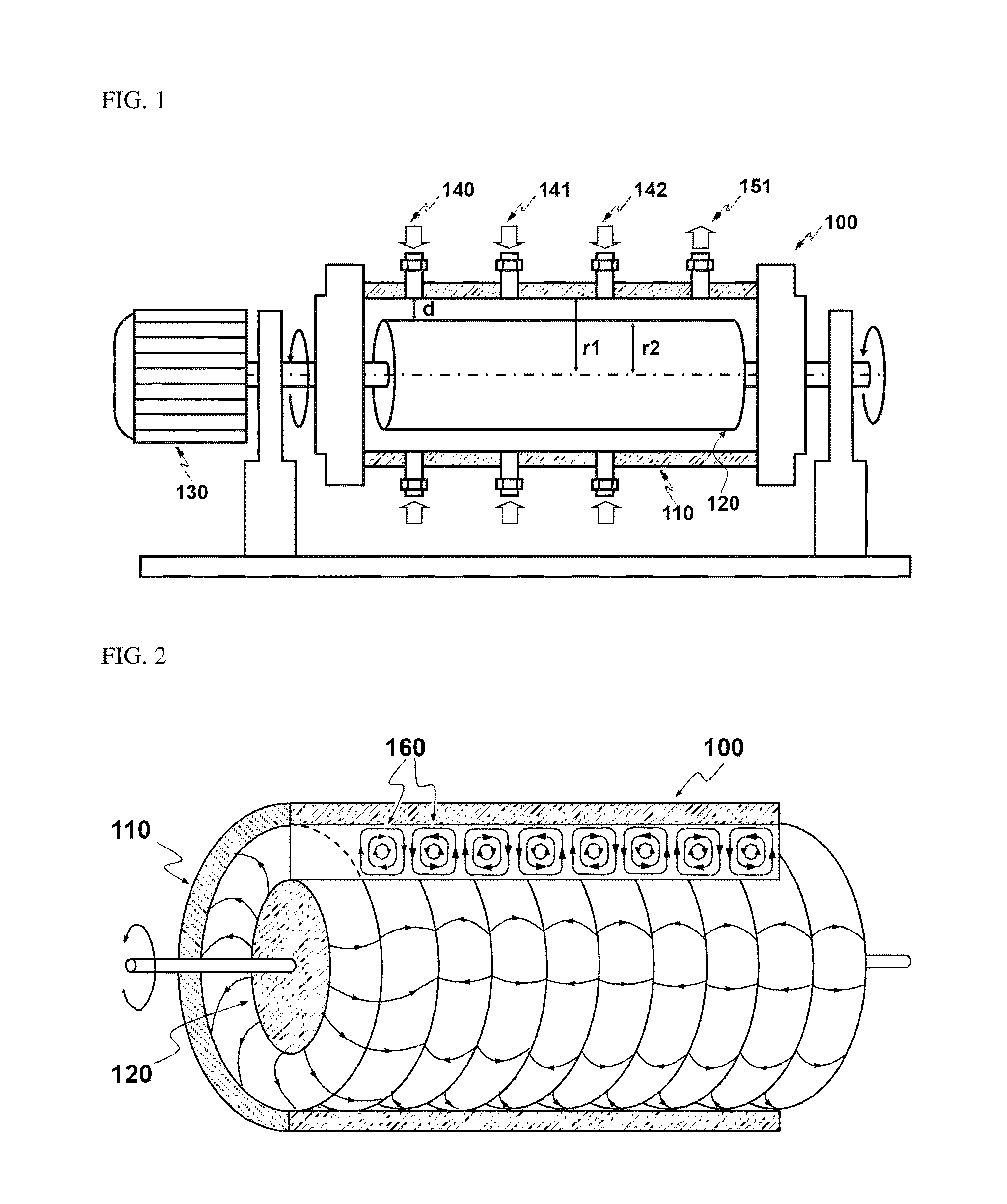

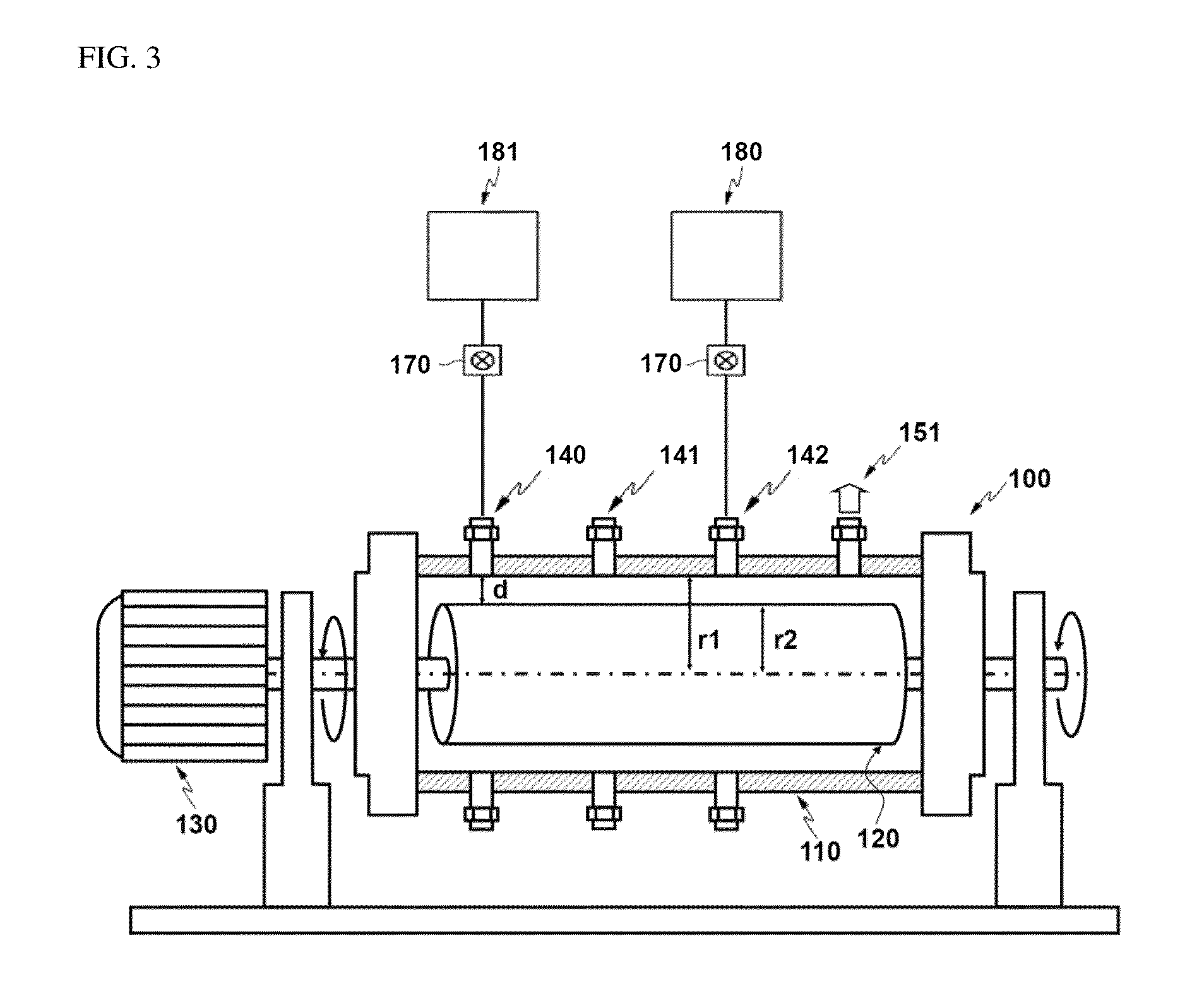

Image

Examples

example 2

[0089]A nickel-cobalt-manganese composite transition metal precursor was prepared in the same manner as in Example 1, except that supply amounts were changed so as to adjust the retention time to 2 hours.

example 3

[0090]A nickel-cobalt-manganese composite transition metal precursor was prepared in the same manner as in Example 1, except that supply amounts were changed so as to adjust the retention time to 3 hours.

example 4

[0091]A nickel-cobalt-manganese composite transition metal precursor was prepared in the same manner as in Example 1, except that supply amounts were changed so as to adjust the retention time to 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com