Construction machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

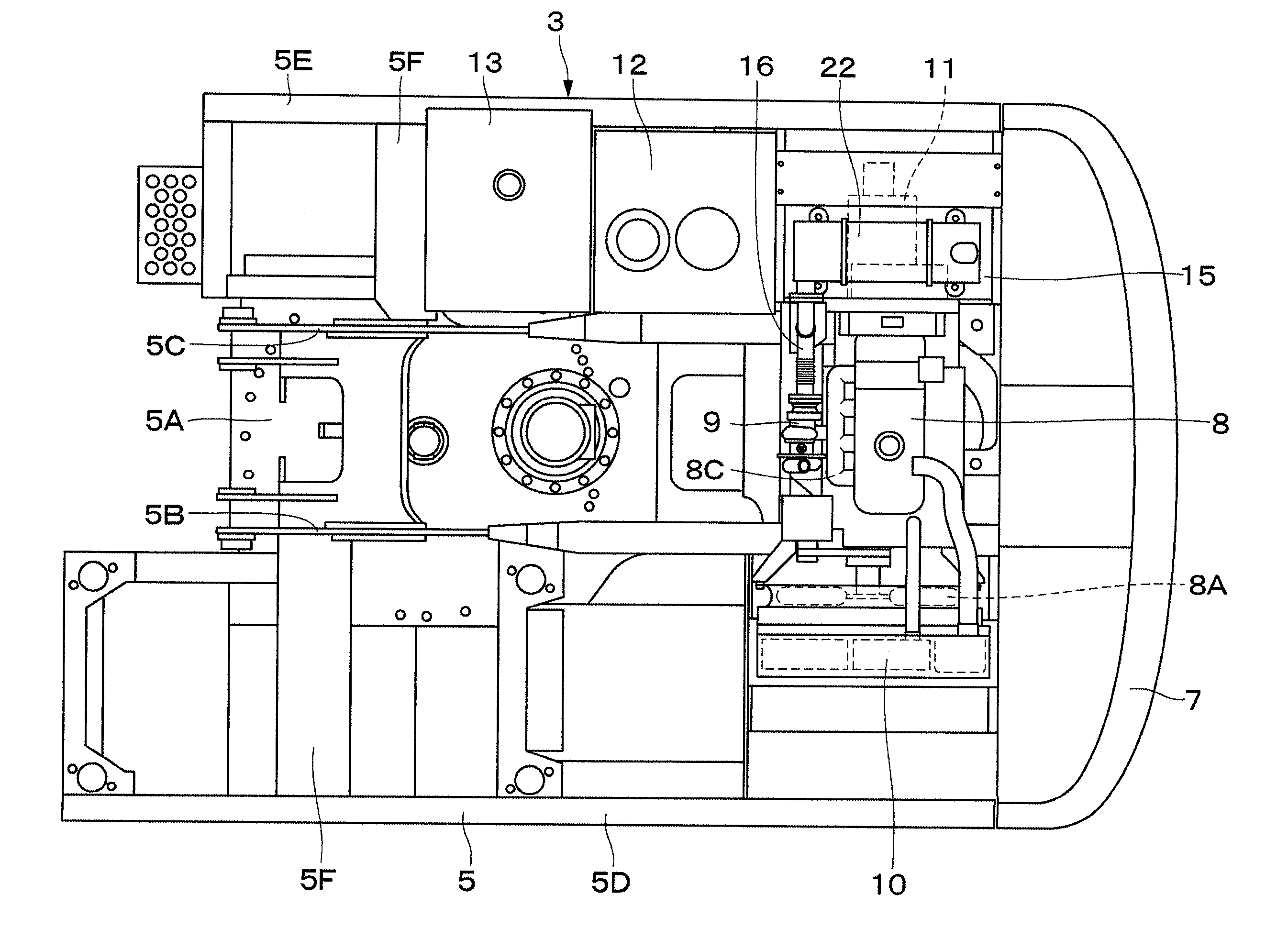

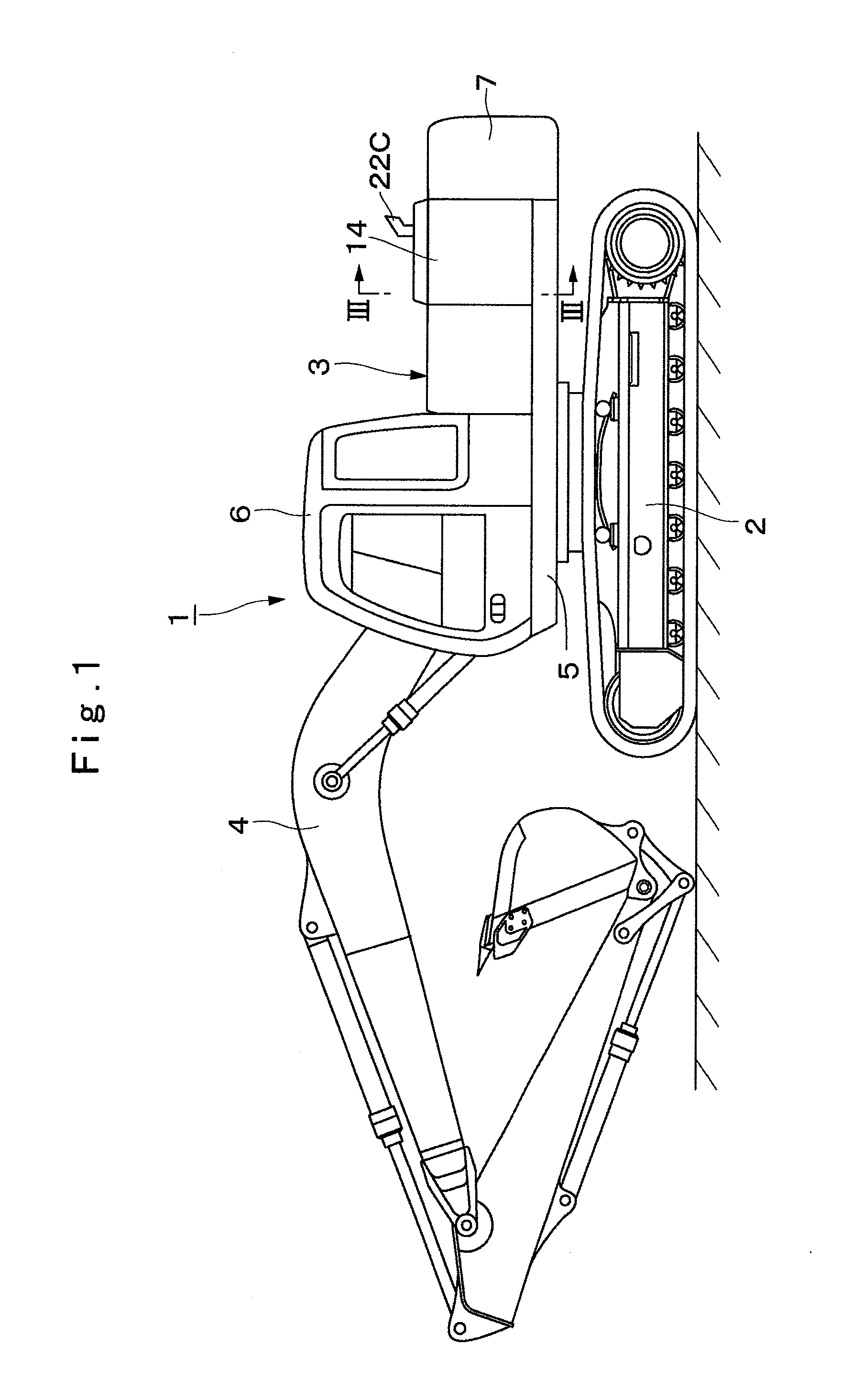

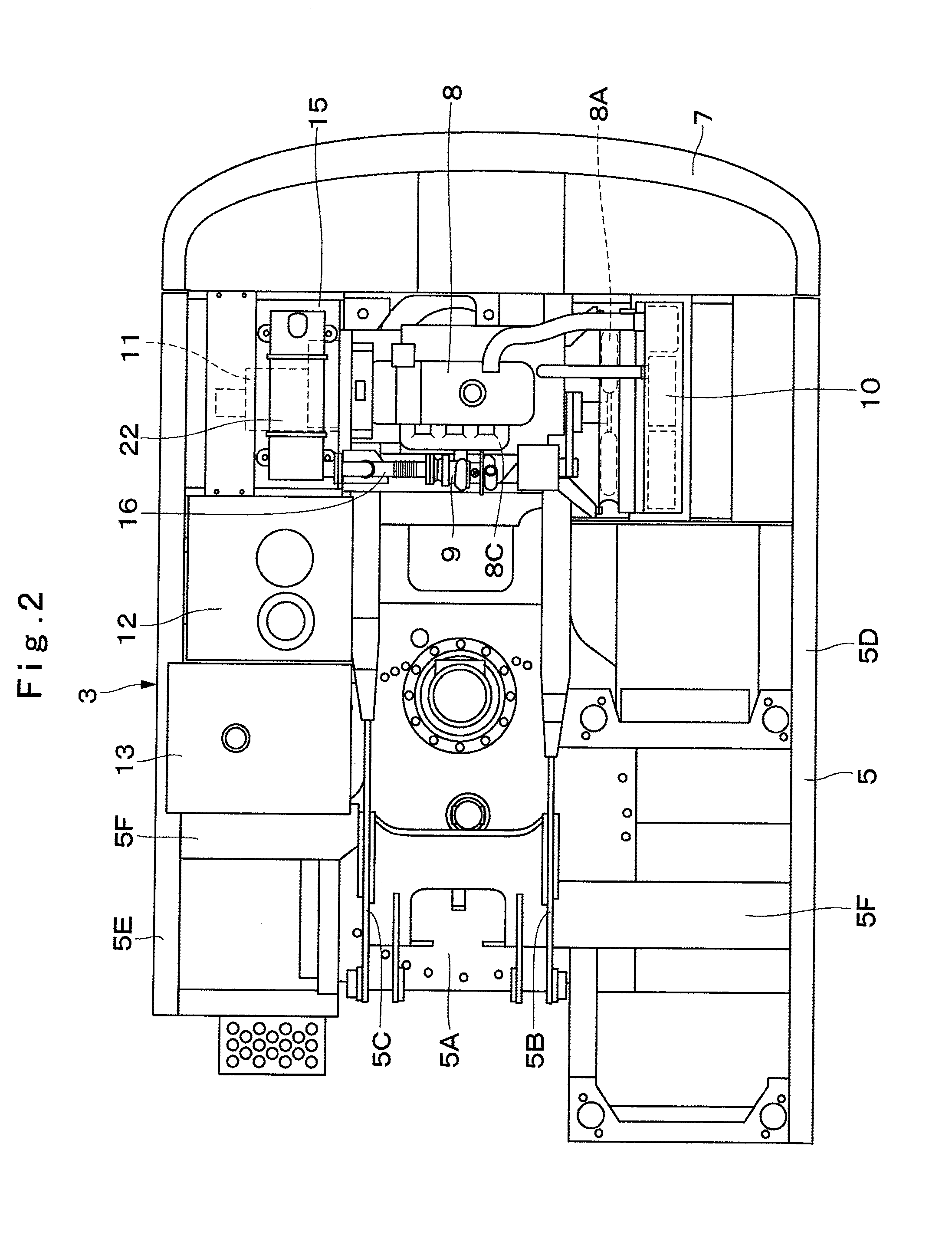

[0041]FIGS. 1 to 6 illustrate a hydraulic excavator according to the present invention.

[0042]In the drawings, designated at 1 is a hydraulic excavator as a construction machine used for an excavating work of earth and sand or the like. This hydraulic excavator 1 is composed of an automotive crawler-type lower traveling structure 2, an upper revolving structure 3 rotatably mounted on the lower traveling structure 2 and constituting a vehicle body together with the lower traveling structure 2, and a working mechanism 4 liftably provided on the front side of the upper revolving structure 3.

[0043]Here, the upper revolving structure 3 constituting the hydraulic excavator 1 will be described in detail. Indicated at 5 is a revolving frame of the upper revolving structure 3, and the revolving frame 5 is constituted as a support structural body. This revolving frame 5 is composed of a bottom plate 5A made of a thick steel plate or the like extending in the front-rear direction, a left vertic...

second embodiment

[0093]That is, during running or working of the hydraulic excavator 1, the exhaust gas post-treatment device 22 mounted on the engine 8 through the support member 31 and the vibration isolating member 22E vibrates in a vibration mode different from that of the engine 8. In this case, vibration between the engine 8 and the exhaust gas post-treatment device 22 can be absorbed by bending deformation of the first bellows pipe 18 and the second bellows pipe 20 arranged in the midway portion of the exhaust pipe 16.

[0094]Thus, similarly to the above described first embodiment, vibration between the engine 8 and the exhaust gas post-treatment device 22 can be stably absorbed by bending deformation of the first bellows pipe 18 and the second bellows pipe 20, and reliability of the hydraulic excavator 1 can be improved. Moreover, vibration can be stably absorbed even if the lengths of each of the bellows pipes 18 and 20 are made smaller, and freedom in arrangement of the exhaust pipe 16 can ...

third embodiment

[0110]That is, during running or working of the hydraulic excavator 1, the exhaust gas post-treatment device 22 mounted on the engine 8 through the support member 41 and the vibration isolating member 22E vibrates in a vibration mode different from that of the engine 8. In this case, the first bellows pipe 44 and the second bellows pipe 46 are provided through the connecting pipe 45 in the midway portion of the exhaust pipe 42 connecting the engine 8 and the exhaust gas post-treatment device 22 to each other. Each of these bellows pipes 44 and 46 is arranged with a positional relationship (more specifically, a positional relationship of crossing at a right angle) in which the axis line X2-X2 direction and the axis line Y2-Y2 direction cross each other.

[0111]As a result, vibration in the front-rear direction of the vehicle body generated between the engine 8 and the exhaust gas post-treatment device 22 can be absorbed by bending deformation of the first bellows pipe 44 in the front-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com