Metalworking fluid composition and method for its use in the machining of compacted graphite iron

a technology of metalworking fluid and graphite iron, which is applied in the direction of additives, petroleum industry, lubricant compositions, etc., can solve the problems of reducing the quality of the part produced, accelerating the rate of tool wear, and reducing the strength and toughness of the part, so as to reduce the wear of the tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0072]In this example, a standard conventional ferrous machining fluid was assessed relative to a fluid described according to embodiments of the current invention.

[0073]Fluid A, useful for the improved machining of compacted graphite iron, was prepared according to embodiments of the present invention having:

[0074]a) about 5 wt % to about 10 wt % ester lubricant;

[0075]b) about 3 wt % to about 7 wt % of a sulfur additive;

[0076]c) 8 wt % to about 16 wt % mineral oil; and

[0077]d) the balance having amines, boric acid, fatty acids, and emulsifiers.

[0078]Fluid A was tested at a concentration of 8%. The machining conditions are as follows:

CGI DrillingWorkpieceGrade 450 CGIToolGehring # 5514 0.25″ dia.Firex coated solid carbideSpeed3000 RPM (196 SFM)Feed10.4 IPM (.00346 ipr)Depth1.25″ through holeFluid8% in 130 ppm waterMeasured Parameters Cutting ForcesTool WearCGI Drilling

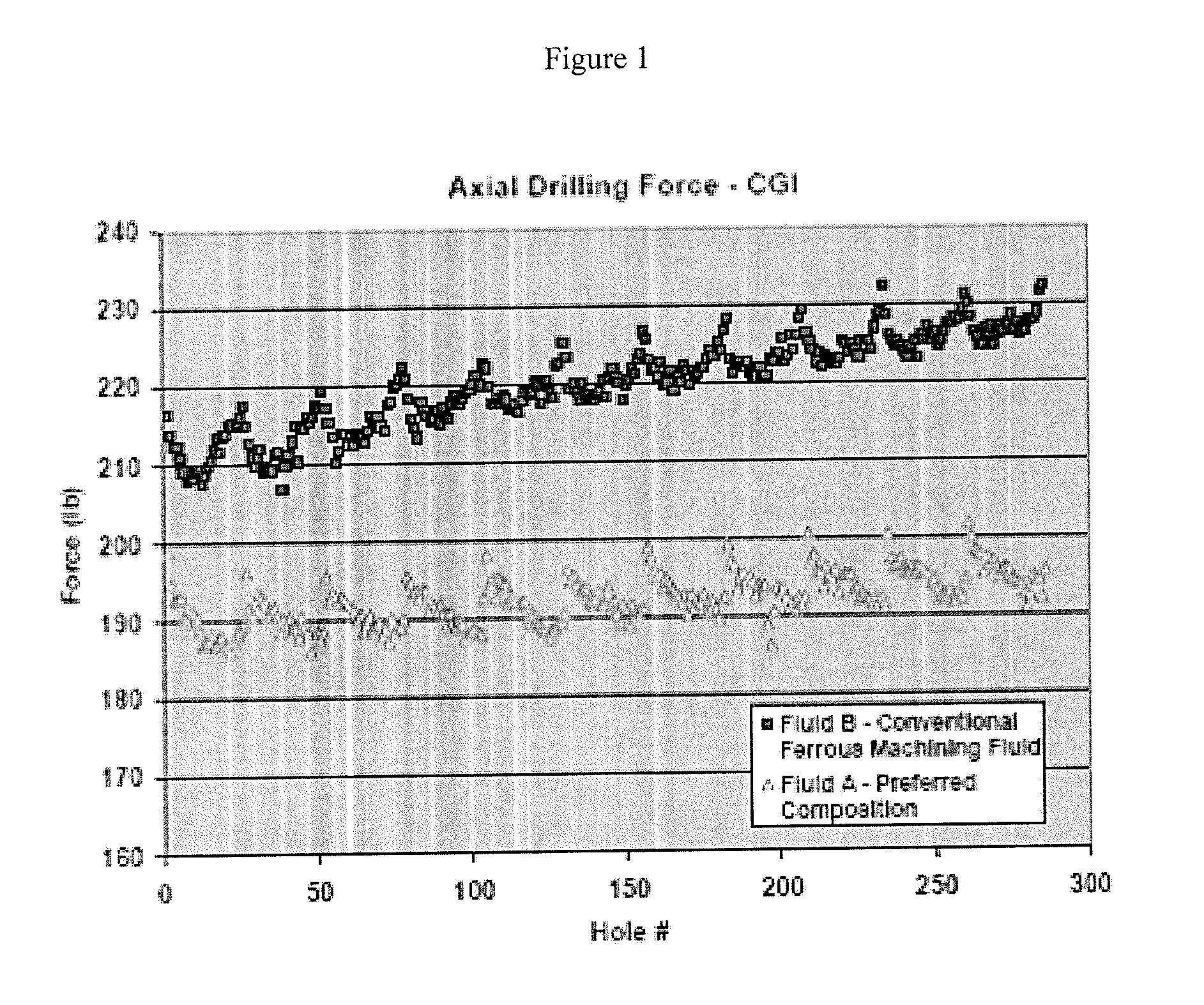

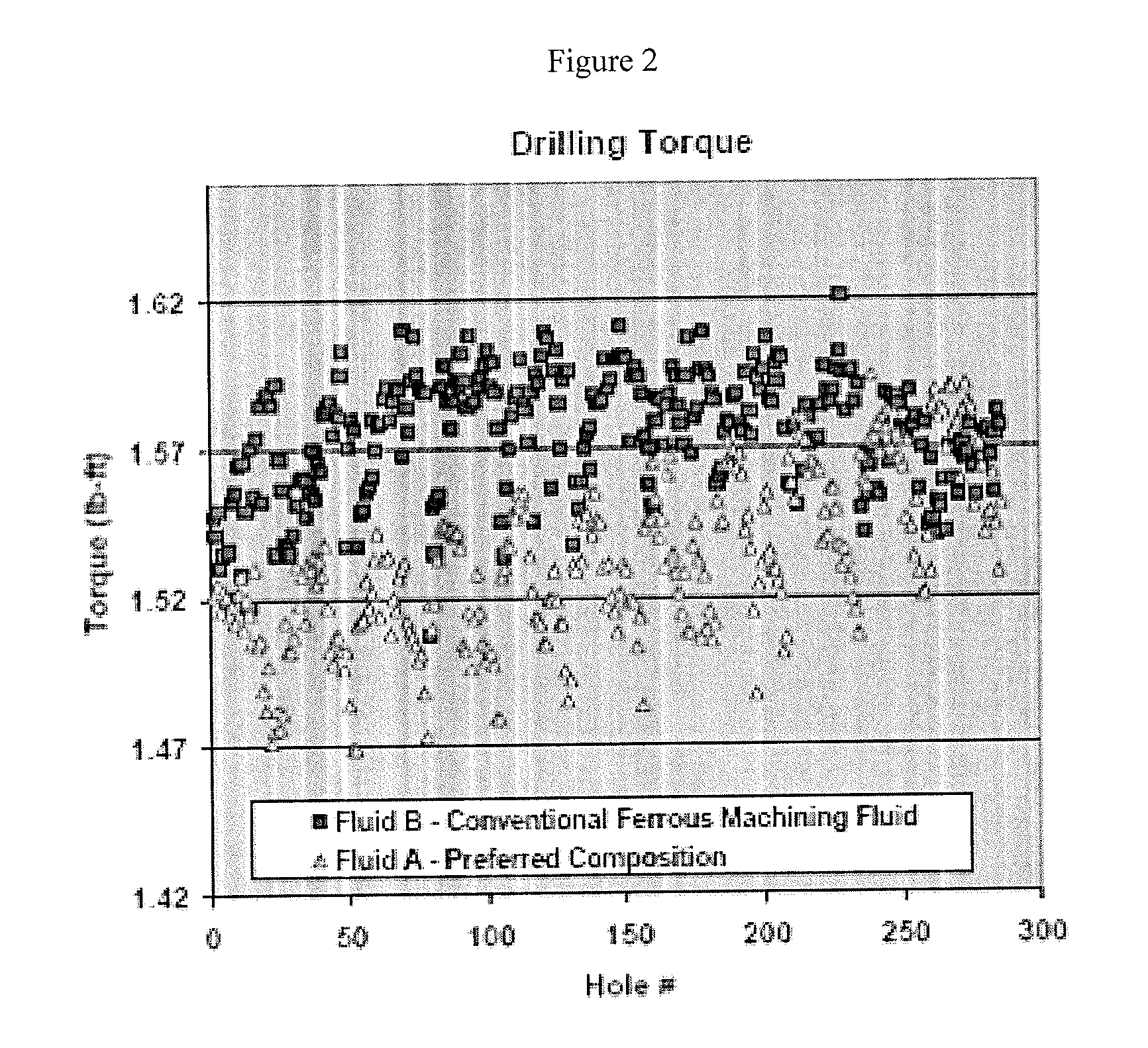

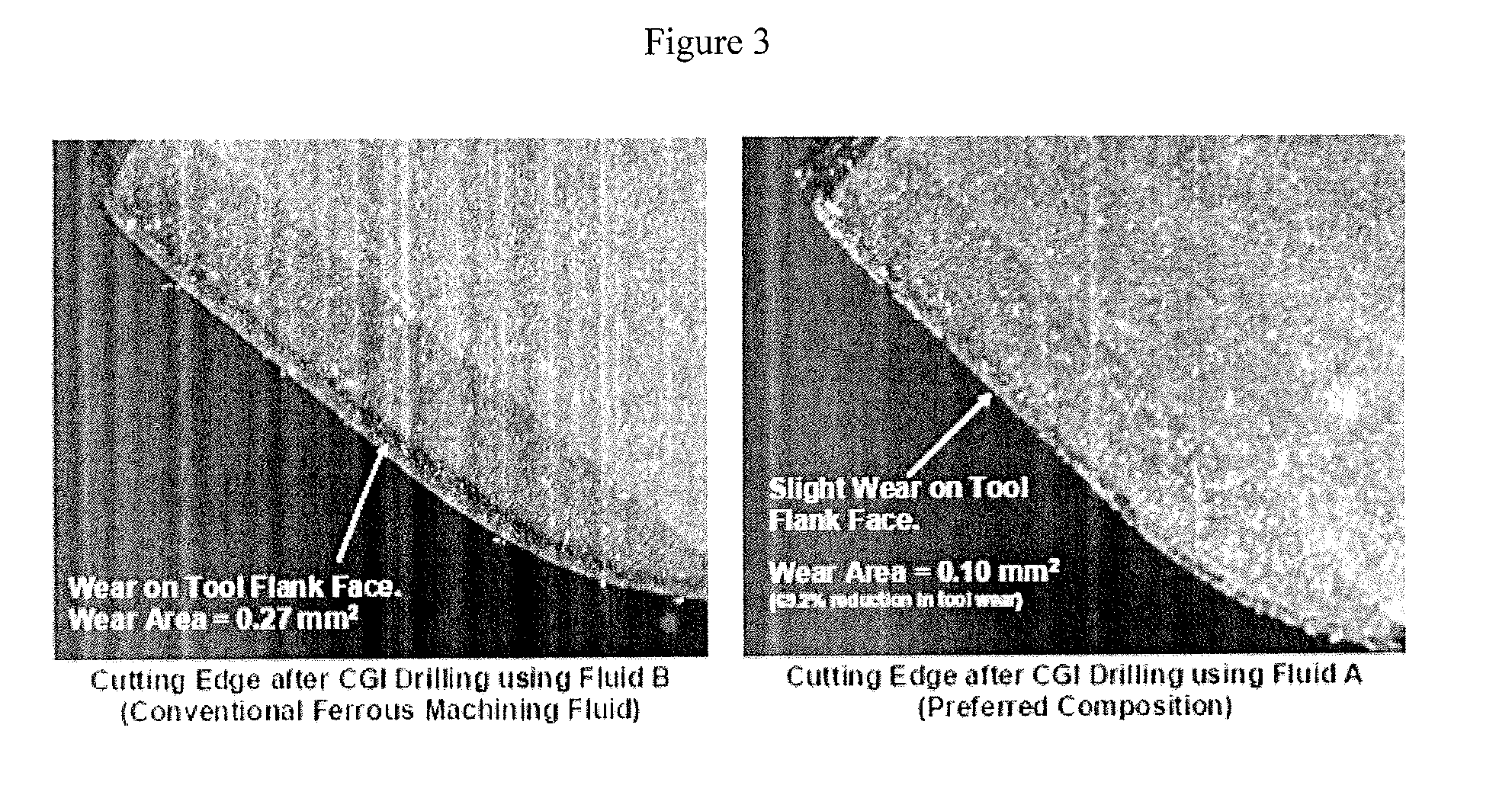

[0079]The axial machining forces and torque (tangential forces) measured during drilling provide a useful indication...

example 2

[0081]Fluid D, useful for the improved machining of compacted graphite iron, was prepared according to embodiments of the present invention having:

[0082]a) about 22 wt % to about 28 wt % of a lubricant ester selected from either the C18 fatty acid ester of 2,2 dimethyl-1,3-propanediol, 2-propanol, 1,1,1, tris(hydroxymethyl)propane, or 1,2,3-propanetriol;

[0083]b) about 2 wt % to about 5 wt % of a dialkyl polysufide selected from those according to Formula 1 whereby R1═CH3, R2═CH3, n=8-10 and m=3-5;

[0084]c) about 3 wt % to about 6 wt % fatty acids comprised of those which include saturated alkyl chains of between 10 to 16 carbons along with longer chain length carboxylic acids comprised of saturated and unsaturated alkyl chains of between 18 to 22 carbon atoms in length.

[0085]d) about 3 wt % to about 8 wt % of a mixture of amine compounds, consisting of those described by Formula 2, whereby R1═H or —CH3, R2═—CH2CH2OH, or cyclic C6H11, and R3═—CH2CH2OH, or cyclic C6H11;

[0086]e) about 3...

example 3

[0090]Fluid F, useful for the improved machining of compacted graphite iron, was prepared according to embodiments of the present invention having:

[0091]a) about 12 wt % to about 18 wt % of a lubricant ester or combination of lubricant esters selected from those of C18 fatty acid esters of 2,2 dimethyl-1,3-propanediol, 2-propanol, 1,1,1, tris(hydroxymethyl)propane, 2-hydroxy-1,3-propanediol, 2,2-bis(hydroxymethyl)-1,3-propanediol, and 1,2,3-propanetriol. b) between 2 and 5% of a dialkyl polysufide selected from those according to Formula 1 whereby R1═CH3, R2═CH3, n=8-10 and m=5-8;

[0092]c) about 1 wt % to about 7 wt % fatty acids selected from those containing saturated and unsaturated chains of between 16 and 22 carbons;

[0093]d) about 8 wt % to about 14 wt % of a mixture of amine compounds, consisting of those described by Formula 2 whereby R1═H or —CH2CH2OH, R2═H, or —CH2CH2OH, and R3═—CH2CH2OH, or —C3H6OH;

[0094]e) about 5 wt % to about 9 wt % of an amine salt of boric acid accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com