Integrated deburring finish machining turning method and cutter

A finishing turning and deburring technology, which is applied in the direction of lathe tools, turning equipment, manufacturing tools, etc., can solve the problem of surface roughness value reduction, reduce surface roughness and tool wear, improve processing efficiency, Easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

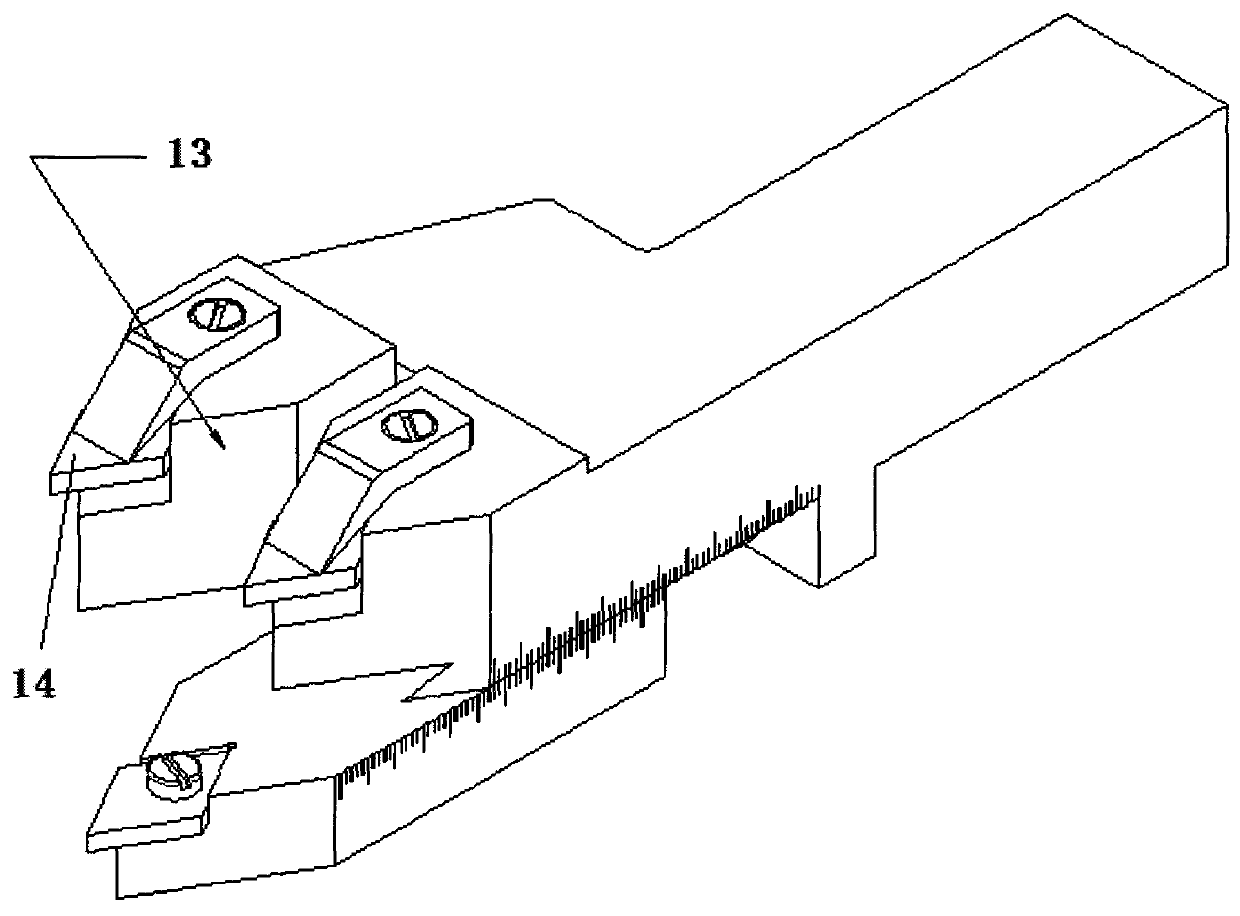

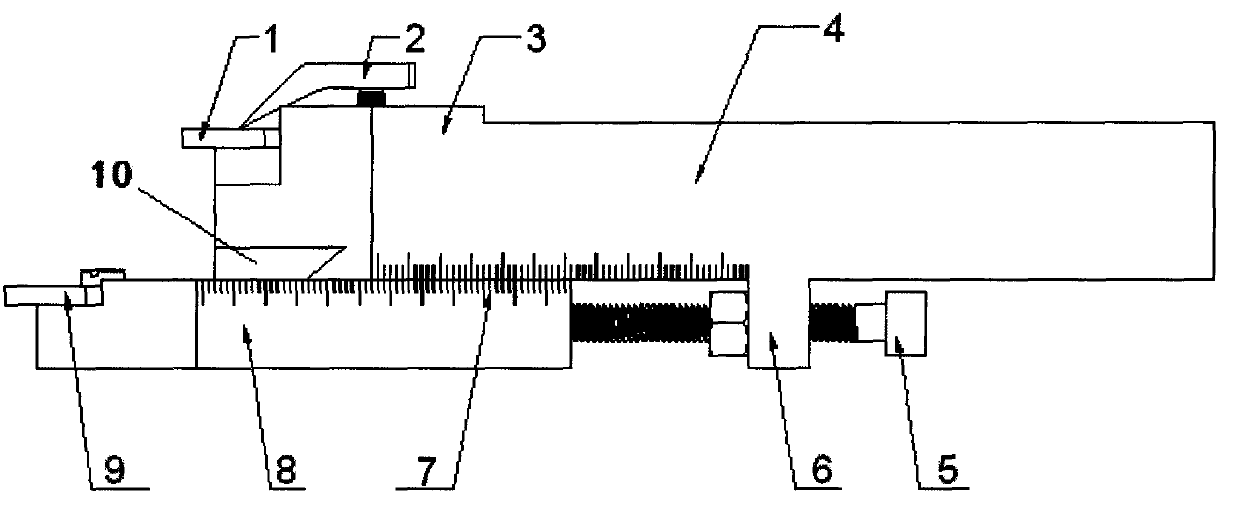

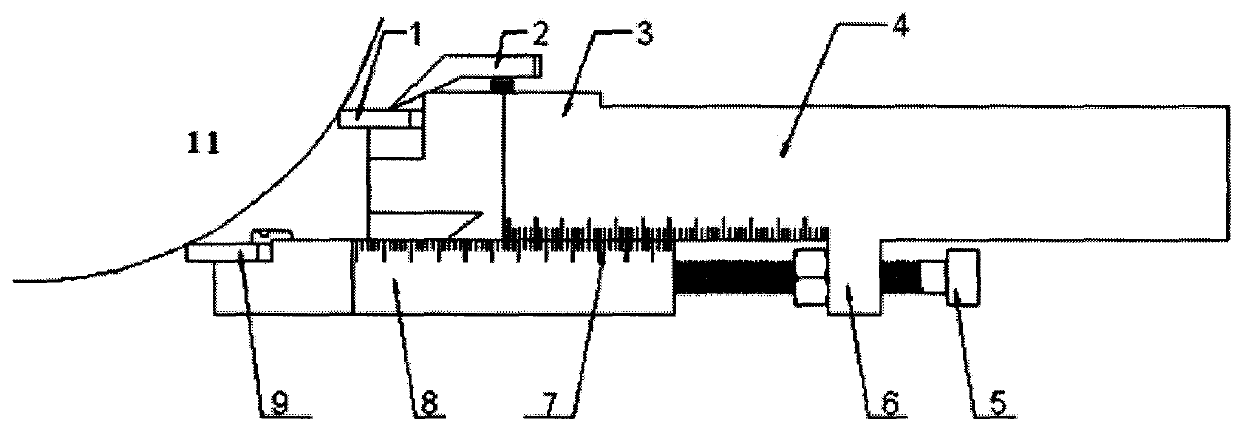

[0020] Such as figure 1 with figure 2 Shown, cutter of the present invention is by 1, cutting blade; 2, pressure head; 3, cutting head; 4, knife handle; 5, precision screw rod; 9. Deburring blade; 10. Dovetail guide rail; 13. Finishing cutter head; 14. Finishing blade composition.

[0021] Such as image 3 As shown, the cutting blade 1 is at the upper part, which is centered with the center of the workpiece; the deburring blade 9 is at the lower part, and the vertical distance between the two base surfaces is L. When the radius of the workpiece is R1, the elongation of the deburring blade 9 is:

[0022] AE = R 1 - R 1 2 - L 2

[0023] At this time, the cutting edge of the cutting blade 1 and the cutting edge of the deburring blade 9 are just on the arc with the workpiece axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com