Drawn heat treated steel wire for high strength spring use and pre-drawn steel wire for high strength spring use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

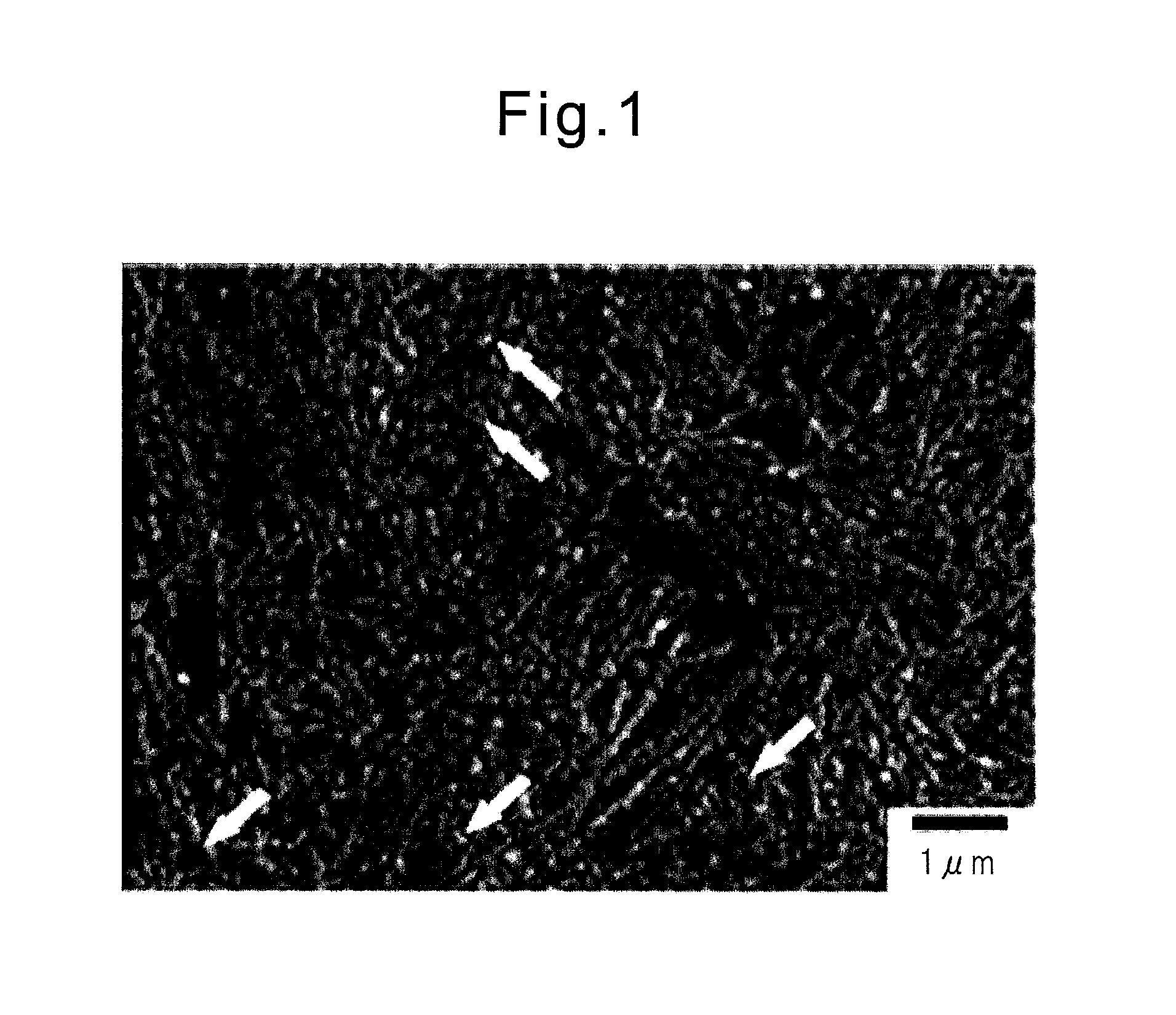

Image

Examples

examples

[0190]Steels having the chemical compositions shown in Tables 1-1 to 1-4 were smelted in a 10 kg vacuum melting furnace and cast to obtained blooms or billets. These vacuum melted materials were hot forged up to φ8 mm. After that, the materials hot forged up to φ8 mm were heated at 1270° C.×4 hr. Further, part of the samples were refined in a 250 ton converter, continuously cast to prepare blooms, then heated at 1270° C.×4 hr or more, then made into cross-section 160 mm×160 mm billets. Furthermore, these were rolled to obtained φ8 mm rolled wire rods. The heating temperature of the billets before rolling was made 1200° C. or more.

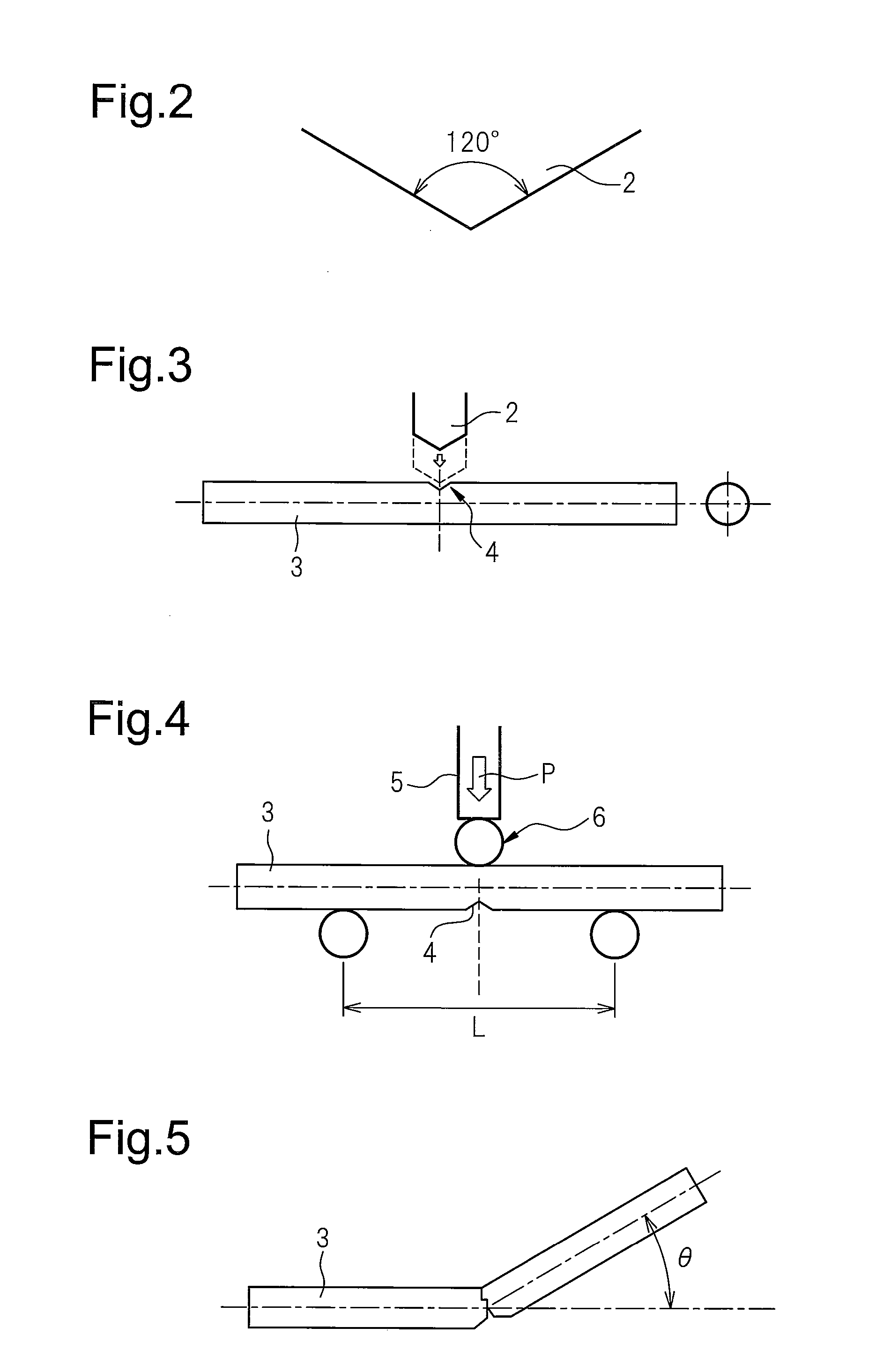

[0191]A diameter 8 mm pre-drawn steel wire (rolled wire rod) is preferably made an easily drawn structure by patenting it before drawing. The heating temperature at the patenting is preferably 900° C. or more so that the carbides etc. sufficiently dissolve. The patenting is performed by heating at 930° C., then charging the sample into a 600° C. flowing bed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com