Substrate processing method

a processing method and substrate technology, applied in the field of substrate processing method, can solve the problems of strong isotropy in etching, inability to achieve the desired shape of a hole or a trench, etc., to achieve the effect of improving processing controllability in the etching process and low energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Hereinafter, illustrative embodiments will be described with reference to the accompanying drawings.

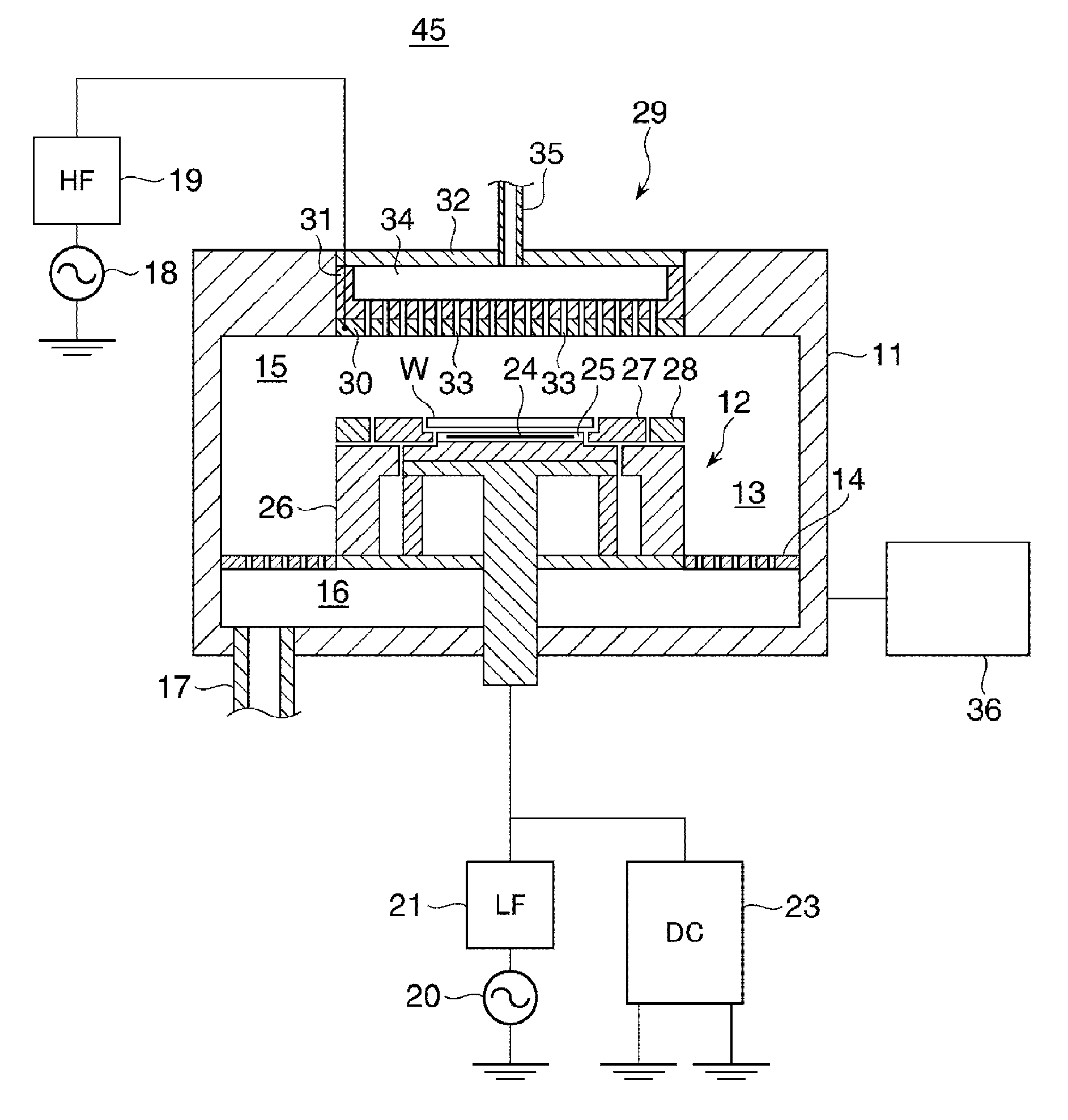

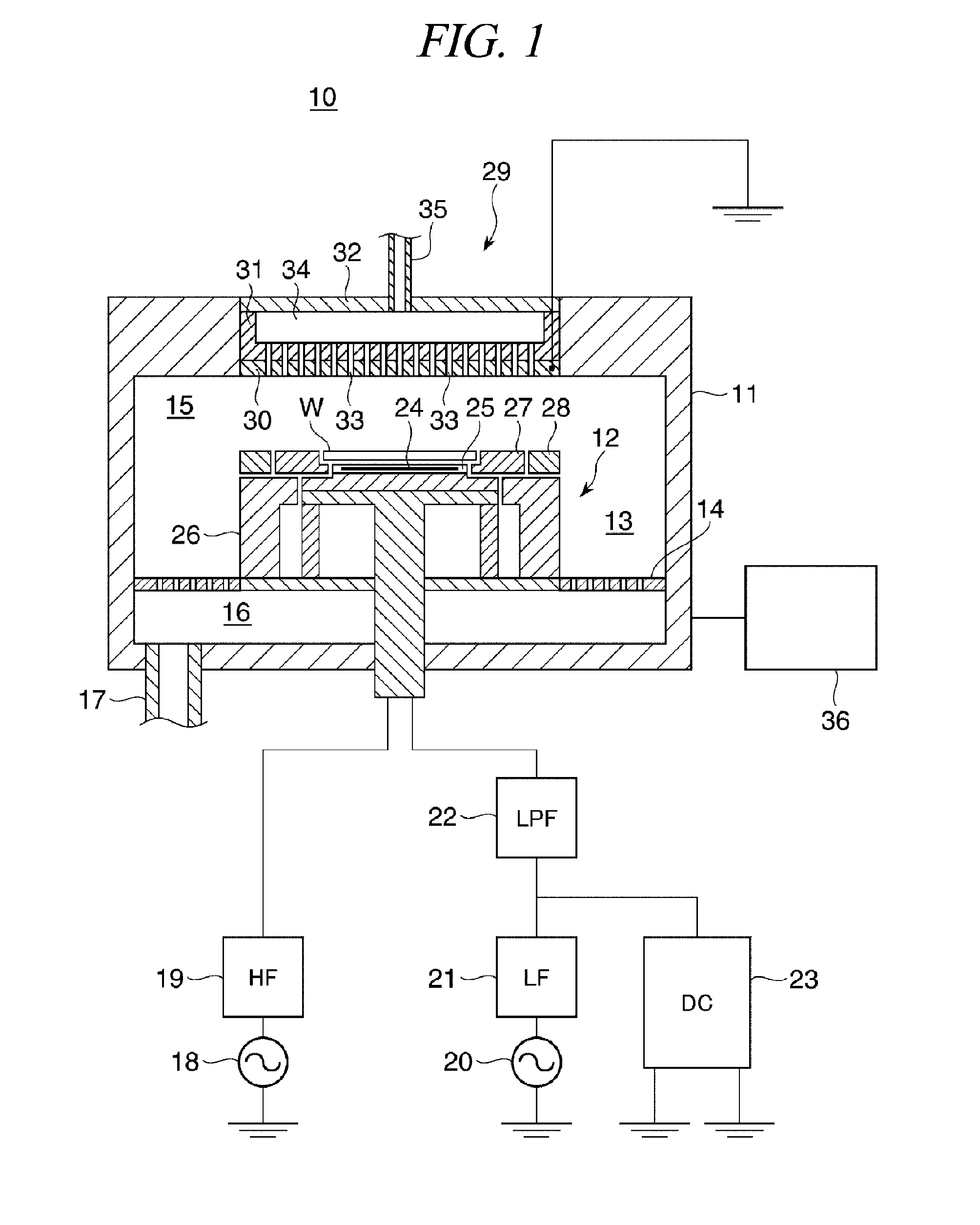

[0026]FIG. 1 is a schematic configuration view of a substrate processing apparatus in accordance with an illustrative embodiment. In the substrate processing apparatus, a plasma etching process is performed on a semiconductor device wafer (hereinafter, simply referred to as a “wafer”) as a substrate.

[0027]In FIG. 1, a substrate processing apparatus 10 includes a chamber 11 for accommodating a wafer W having a diameter of, e.g., about 300 mm, and a circular column-shaped susceptor 12 (mounting table) for mounting there on the wafer W is provided within the chamber 11. In the substrate processing apparatus 10, a side exhaust path 13 is formed between an inner sidewall of the chamber 11 and a side surface of the susceptor 12. An exhaust plate 14 is provided at a certain portion of the side exhaust path 13.

[0028]The exhaust plate 14 is a plate-shaped member having a multiple number ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com