Permaback, Long Life, Bleach Proof Latex Coated Rugs

a technology of bleach-proof latex and rugs, applied in weaving, automatic machines, transportation and packaging, etc., can solve the problems of short cracking and splitting of coatings, cracking and peeling of latex, etc., and achieves the effect of preventing yellowing and prolonging the life of latex coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Particulars of Latex Coating Mixture with Cotton Yarn Tuft

Latex Composition Recipe for Drylon Tufted Rug:

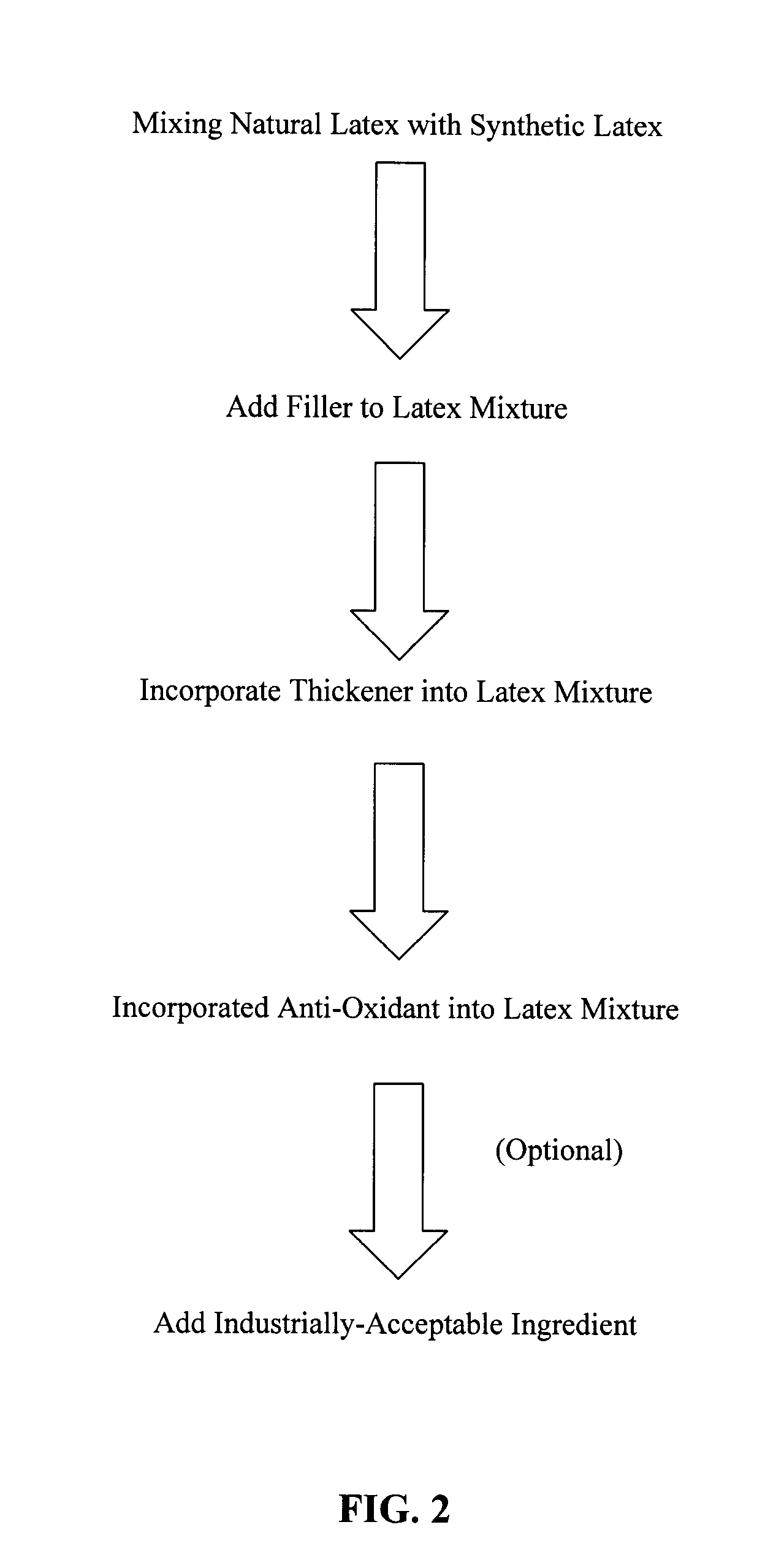

[0054]

Trial lotMixing quantityPartParticular(391 kgs latex)Part ANatural latex (Polyisoprene-60%Ammonia centrifuged naturalrubber)SBR (Bunatex ® T 4320 - Aqueous40%dispersion of styrene and 1,3Butadiene)Potassium Oleate soap10 kgs Water9 kgsAnti Oxidant Phenolic Acid2 kgsFiller Calcium / magnesium120 kgs Carbonate MgCO3 / CaCO3Thickener Potassium Acrylate / 2 kgsSodium polyacrylatePart BGEL Ammonium Acetate 3%(duringapplication)Part CAccelerator Mix Of Sulphur and 3%(duringZinc Oxideapplication)

[0055]

DesignSANNYPartyWILMachine 3 / 16 cutYarn6 / 6 OE 3.2 TPI S TWIST 100% COTTONmaterial codeFCC0788053MPFDN01Size21 × 34Backing110 ppCoating typefoam coatlatex typenatural and synthetic latex mixture (Permaback)Process routeReactive dyeingpercentage %ozgsminchcmgm / 100 mtrGmTufting width151384tuft yarn gsm28958backing width165420backing gsm3110Length100tuft rugs gsm311068...

example2

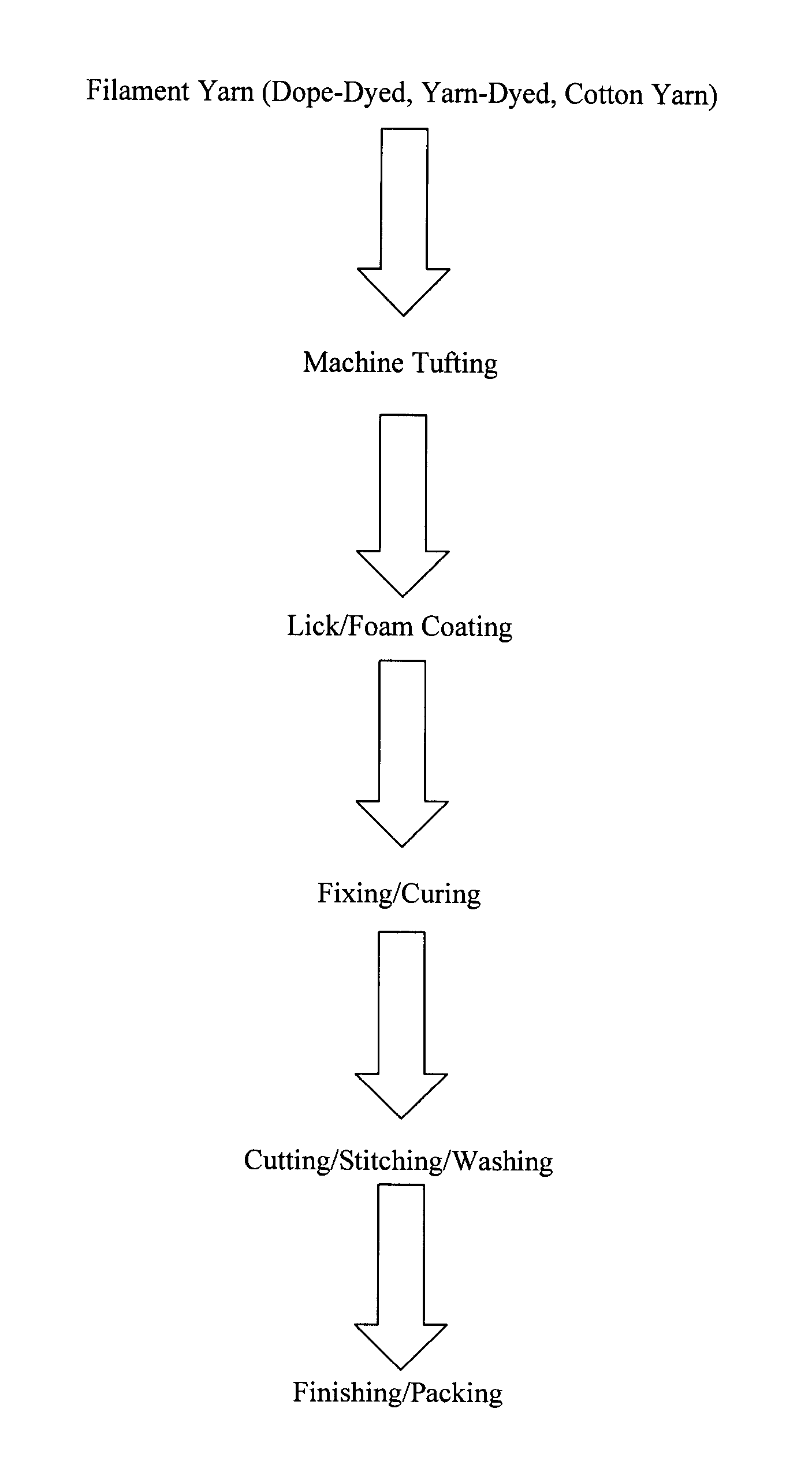

[0064]A process for making a latex-coated rug in accordance with the invention comprises use of dope dyed, micro denier, cabled and heat set polyester yarn, or micro denier per filament, cabled, heat set, yarn dyed, antimicrobial treated polyester yarn, for tufting of rugs, thereby eliminating the process of batch dyeing after the formation of rugs, further ensuring that the rugs are bleach safe, quick drying, anti-skid, long life and stain resistant. Such a process of making a latex-coated rug in accordance with the invention comprises the following steps:[0065](a) Tufting of micro-denier, dope dyed, cabled and heat-set polyester filament, or micro denier per filament, cabled, heat set, yarn dyed, antimicrobial treated polyester yarn, on cheeses, which is creeled on tufting machine to form a tufted fabric roll;[0066](b) loading the tufted rolls of step (a) on a latex coating machine followed by application of the latex composition coating to form a latex-coated rug fabric;[0067](c)...

example 3

Latex Composition Recipe for Drylon Yarn Tuft.

[0075]

Trial lotMixing QuantityPartParticular(391 kgs latex)Part ANatural latex (Polyisoprene-60%Ammonia centrifuged naturalrubber)SBR (Bunatex ® T 4320 -40%Aqueous dispersion of styreneand 1,3 Butadiene)Potassium Oleate soap10 kgs Water9 kgsAnti-Oxidant Phenolic Acid2 kgsFiller Calcium / magnesium120 kgs Carbonate MgCO3 / CaCO3Thickener Potassium Acrylate / 2 kgsSodium polyacrylatePart BGEL Ammonium Acetate 3%(duringapplication)Part CAccelerator Mix Of Sulphur and 3%(duringZinc Oxideapplication)

Technical Specification:

[0076]

DesignGEMINYIPartyWILMachine 3 / 16 cutYarn1200 / 2 DENIER 1 DPF 3.3 TPI S-TWIST 100%DRYLONmaterial codeFCC0787053MPFDN01Size21 × 34Backing100 ppCoating typefoam coatlatex type“PERMABACK”Process routeWashing and softnesspercentage %Ozgsminchcmgm / 100 mtrgmTufting width151384tuft yarn gsm28958backing width165420backing gsm3110Length100tuft rugs gsm311068grey tufted rugs wt / 100 mtr409498yarn waste1yarn wt369143yarn scrap1846backin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com