Hic-resistant thick steel plate and uoe steel pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

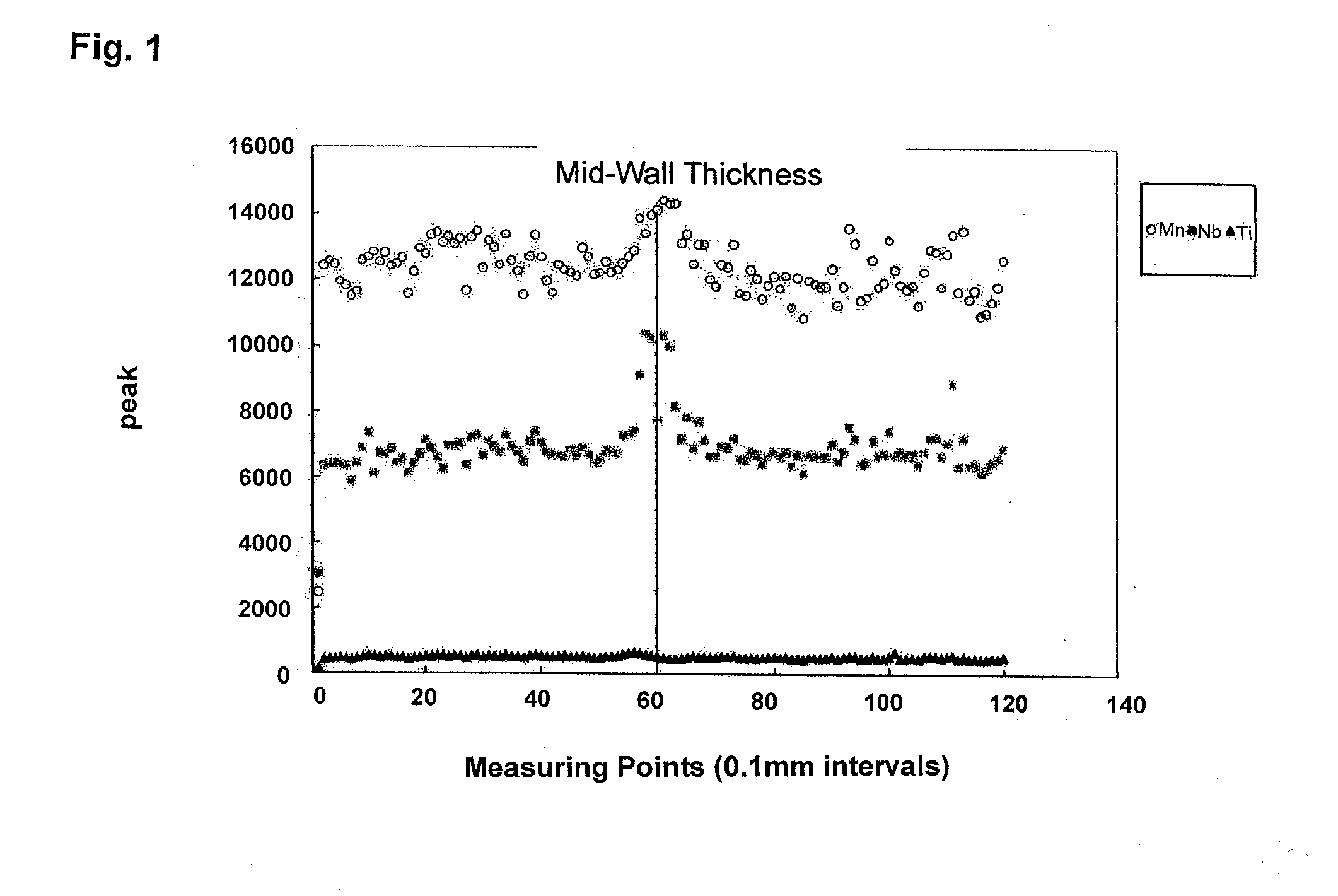

Image

Examples

example 1

[0091]The present invention will be explained more specifically while referring to examples.

[0092]Steels Nos. 1-14 having the chemical compositions and Ar3 points shown in Table 1 was subjected to continuous casting using a continuous casting machine of a vertical bending type with a thickness of 300 mm and a width of 2300 mm at a casting rate of at least 0.7 meters per minute and at most 0.8 meters per minute to obtain a cast slab.

[0093]The resulting cast slab was heated to at least approximately 1100° C. and at most approximately 1200° C., and then it was subjected to hot rolling to give a plate thickness of around 25.4 mm under conditions such that the finish rolling temperature was at least approximately 750° C. and at most approximately 850° C. Immediately after hot rolling, the plate was water cooled. Water cooling was stopped at a temperature of at least approximately 450° C. and at most approximately 550° C. and followed by air cooling. The cooling rate during water cooling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com