Method And Device For Producing Operating Materials Or Fuels

a technology of operating materials and fuels, applied in the direction of fuels, charging-discharge devices, waste based fuels, etc., can solve the problem of limited use of operating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

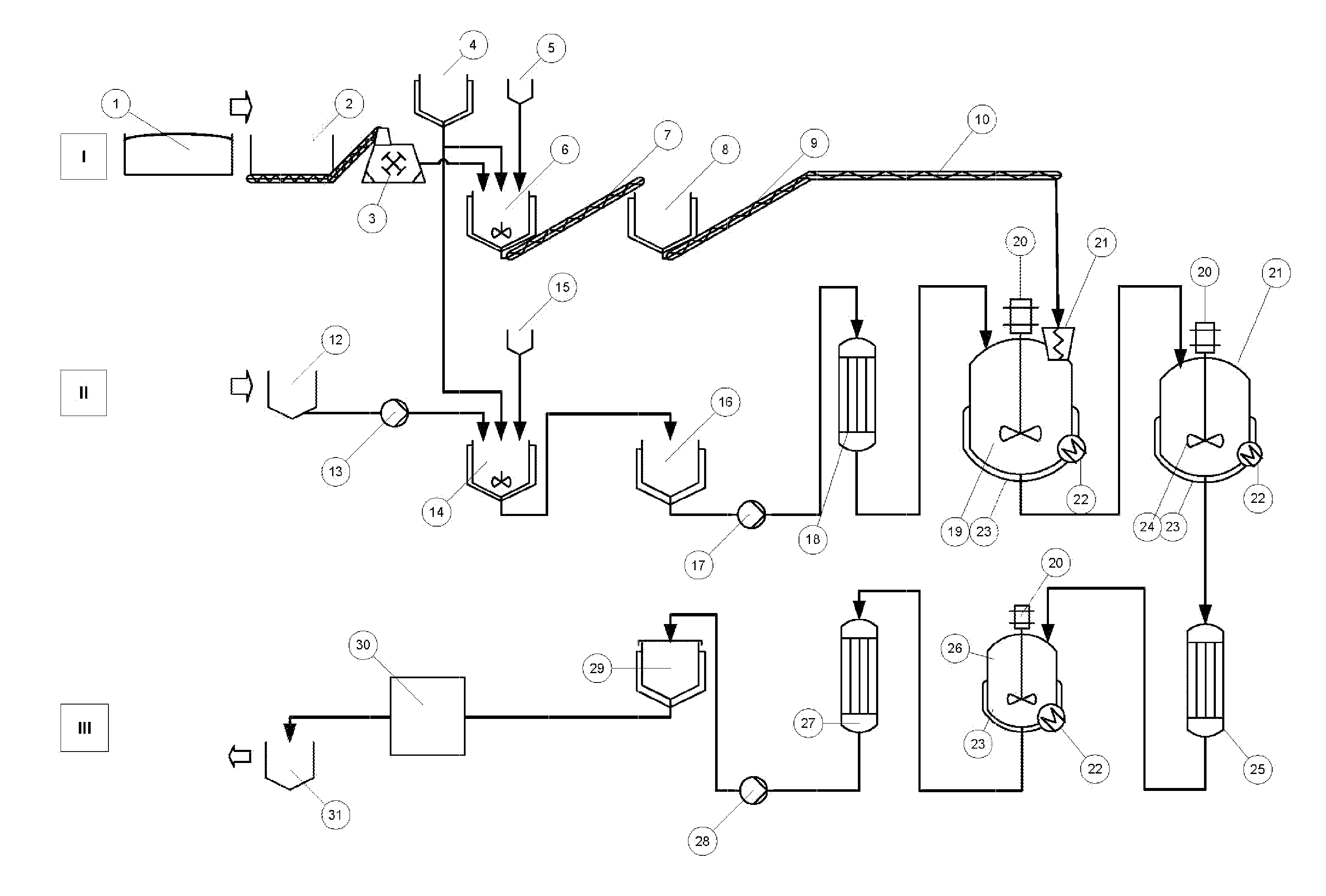

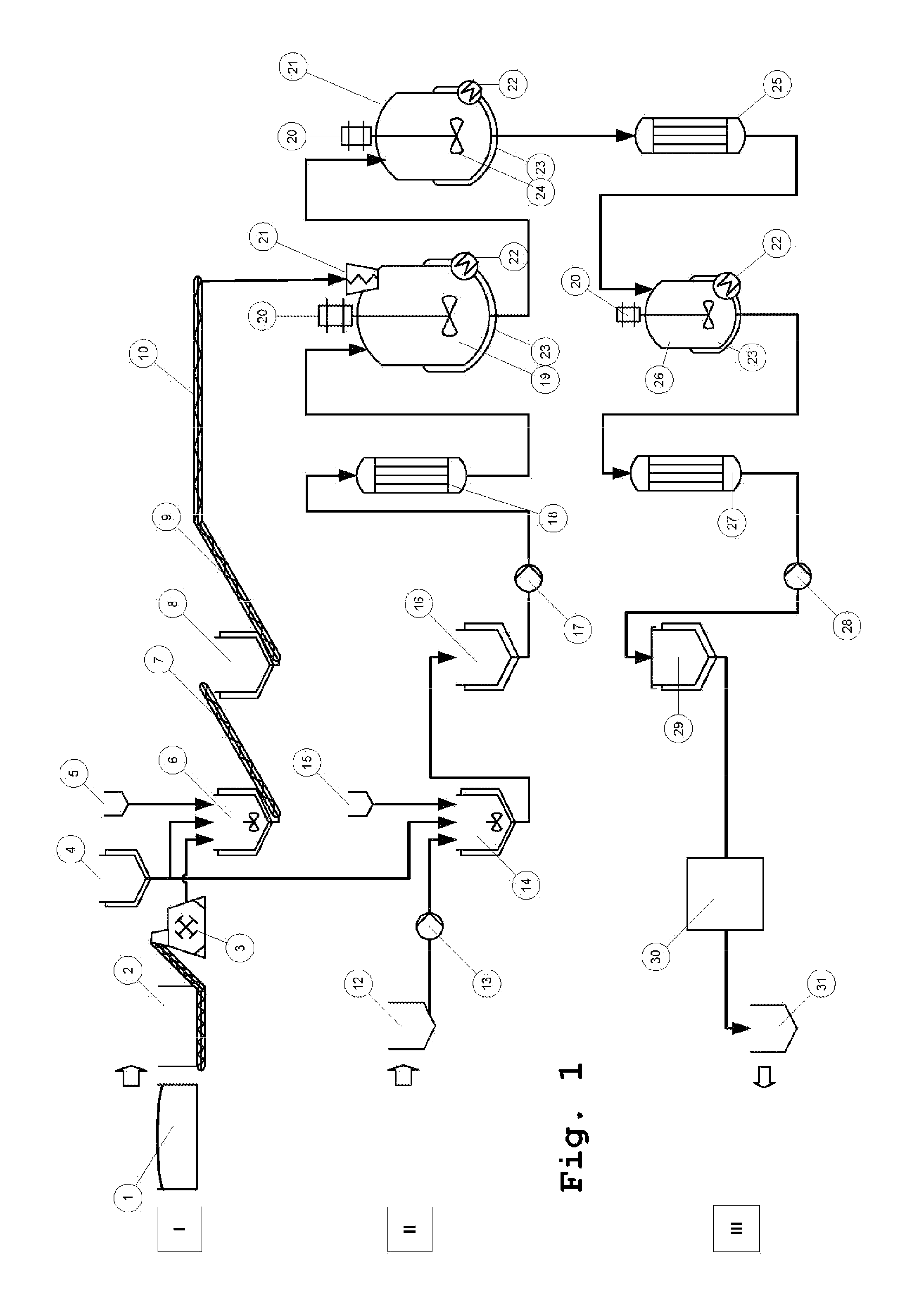

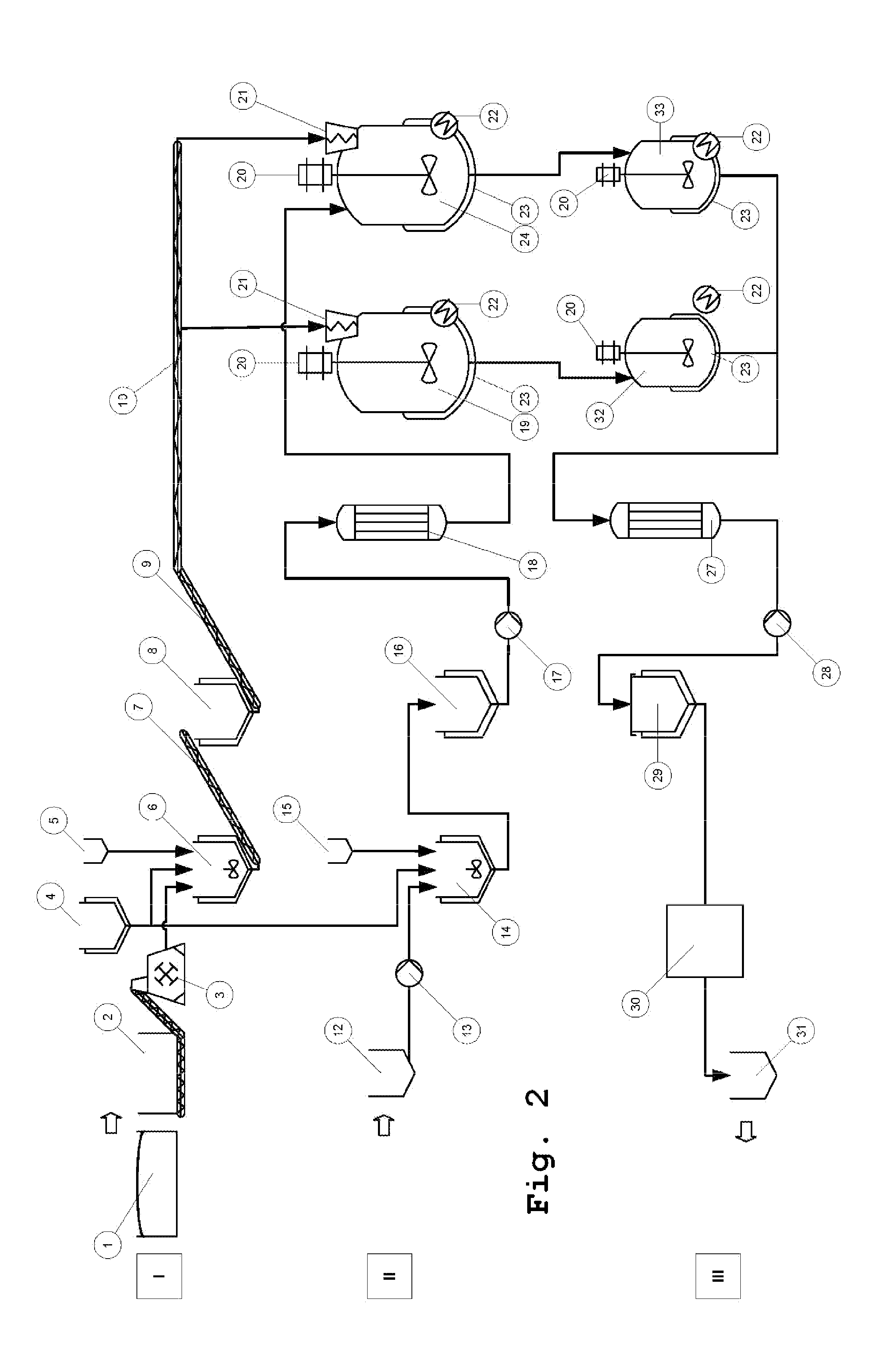

Image

Examples

Embodiment Construction

It is the object of the invention to develop methods and devices, by means of which fuels, humus, carbon-containing materials as well as Maillard or Maillard-like reaction products can be manufactured economically and with high efficiency from a solid-fluid mixture, in particular, on an industrial scale. The object is achieved according to the invention by the objects of the independent claims. Advantageous further developments of the objects of the invention result from the dependent claims.

The object is solved by advantageous method for the hydrolysis and / or production of materials or fuels, humus, Maillard or Maillard-like reaction products from a solid-fluid mixture of water and a carbon-containing component and for the treatment thereof, wherein the solid-fluid mixture is treated at a temperature of over 100° C. and a pressure of over 5 bar in a reactor for at least 1 hour. According to the invention, feed materials that cannot be pumped are fed into the at least one reactor vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com