Roofing granules with high solar reflectance, roofing products with high solar reflectance, and process for preparing same

a technology of solar reflectance and roofing products, applied in the field of roofing granules and roofing products, can solve the problems of reducing the effective service life of such roofs, affecting the appearance of the roof, and affecting the service life of the roof,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

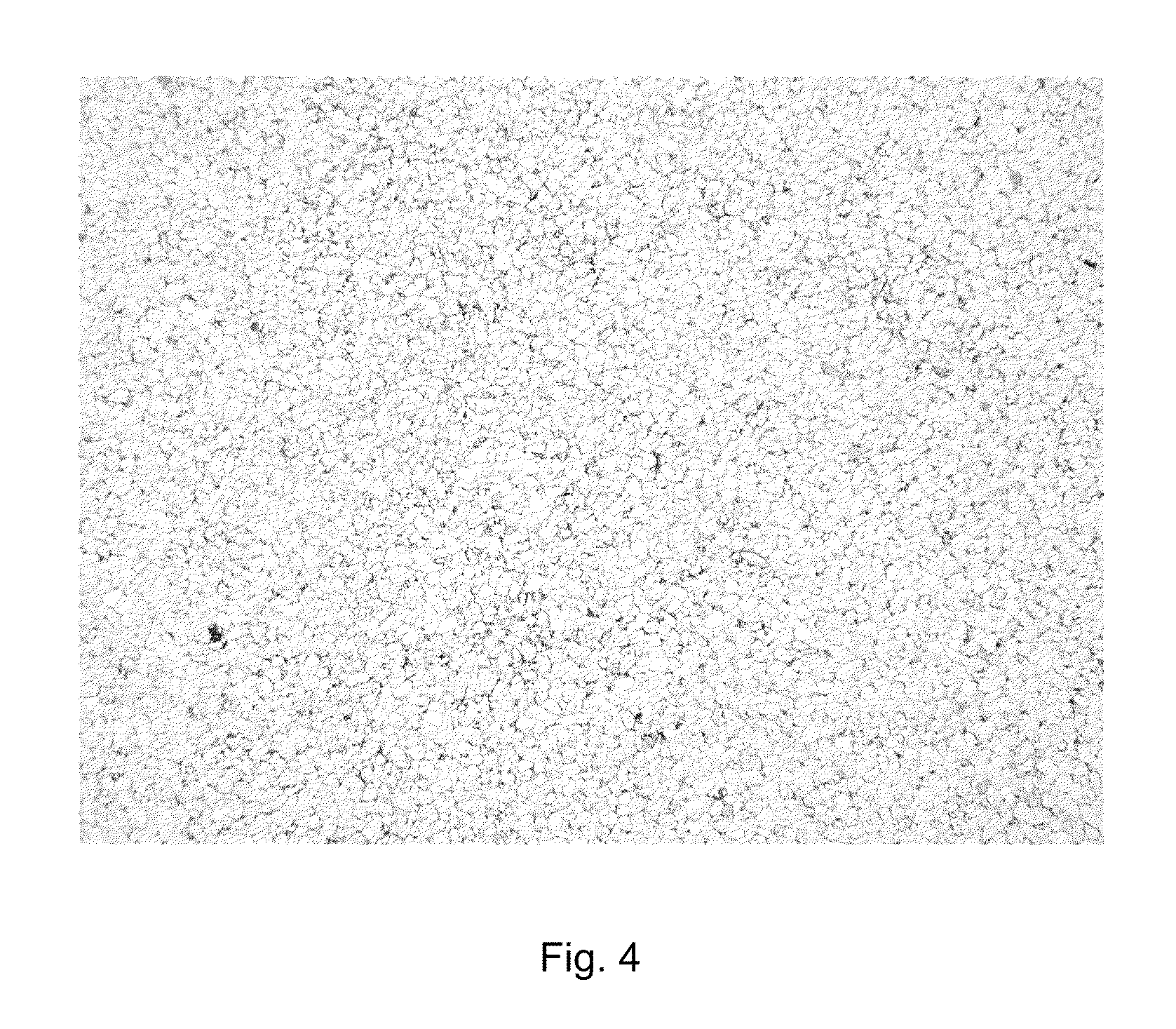

[0099]140 Kg of slate granules (PN15 slate granules, available from ARTI-Groupe CARLAC Parc d'Entreprises I'Esplanade 7, rue Paul-Henri Spaak F-77462 Saint Thibault des Vignes, France,) were employed as base particles. A representative base particle is shown in the micrograph of FIG. 5. The base particles were encapsulated with a white coating material using a fluidized bed coater (Model 1800 with W18-3 plate and CPI-#2 tip spray nozzle, available from The Coating Place Inc., Verona, Wis.). A representative roofing granule is shown in the micrograph of FIG. 6. The highly reflective coating consisted of 35.7 Kg of sodium silicate (Grade 40 from OxiChem Corp, Dallas, Tex.), 59.4 Kg water, 30 Kg of titanium dioxide pigment (R101 from DuPont Corp., Wilmington, Del.), and 15 Kg of kaolin clay (AF grade Snobrite from Unimin Corp). The coating is prepared by blending the ingredients in a tank using an air-driven mechanical agitator with air pressure of 80 psi till reaching uniform dispersi...

example 2

[0101]The particle size distribution of a sample of the slate particles used to form coated roofing granules of Example 1 was determined using a CPA Haver videogranulometer (No. Serie 061). The measured particle size distribution is provided in Table 2 below.

TABLE 2MinimumMaximumSievepercentpercentsize (mm)remainingremaining3.150022.500162.0006141.60012201.00012190.80010170.6307150.500360.315260.2500201

example 3

[0102]The coated roofing granules of Example 1 were inspected and representative flakes were selected by eye. Particle shape was determined using an Olympus SZ-PT stereo microscope with 4× objective and 10× eyepiece, coupled with VIA-170 image system with pre-calibrated dimension measurement to measure the length (L), width (W), and thickness (T). The results of the measurements are reported in Table 3 below.

TABLE 3aspectaspectParticlewidthlength L,thicknessratioratioNo.W, mmmmT, mmL / WL / T12.13863.39850.46421.5891247.32119822.3542.68470.49011.1404845.47786232.21293.81020.60891.7218136.25751442.22773.17960.62191.4273025.11271952.71783.56930.2451.31330514.5685761.89363.17960.37131.679138.56342672.07923.28030.36391.5776749.0142982.3023.14451.06191.3659862.96120291.80452.24670.2451.2450549.170204101.3964.80.49013.4383959.79392111.96042.60150.28221.3270259.218639121.58171.83940.30451.1629266.040722130.95791.80440.34161.8837045.282201140.68321.27880.2451.871785.219592152.07923.24530.28221....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com