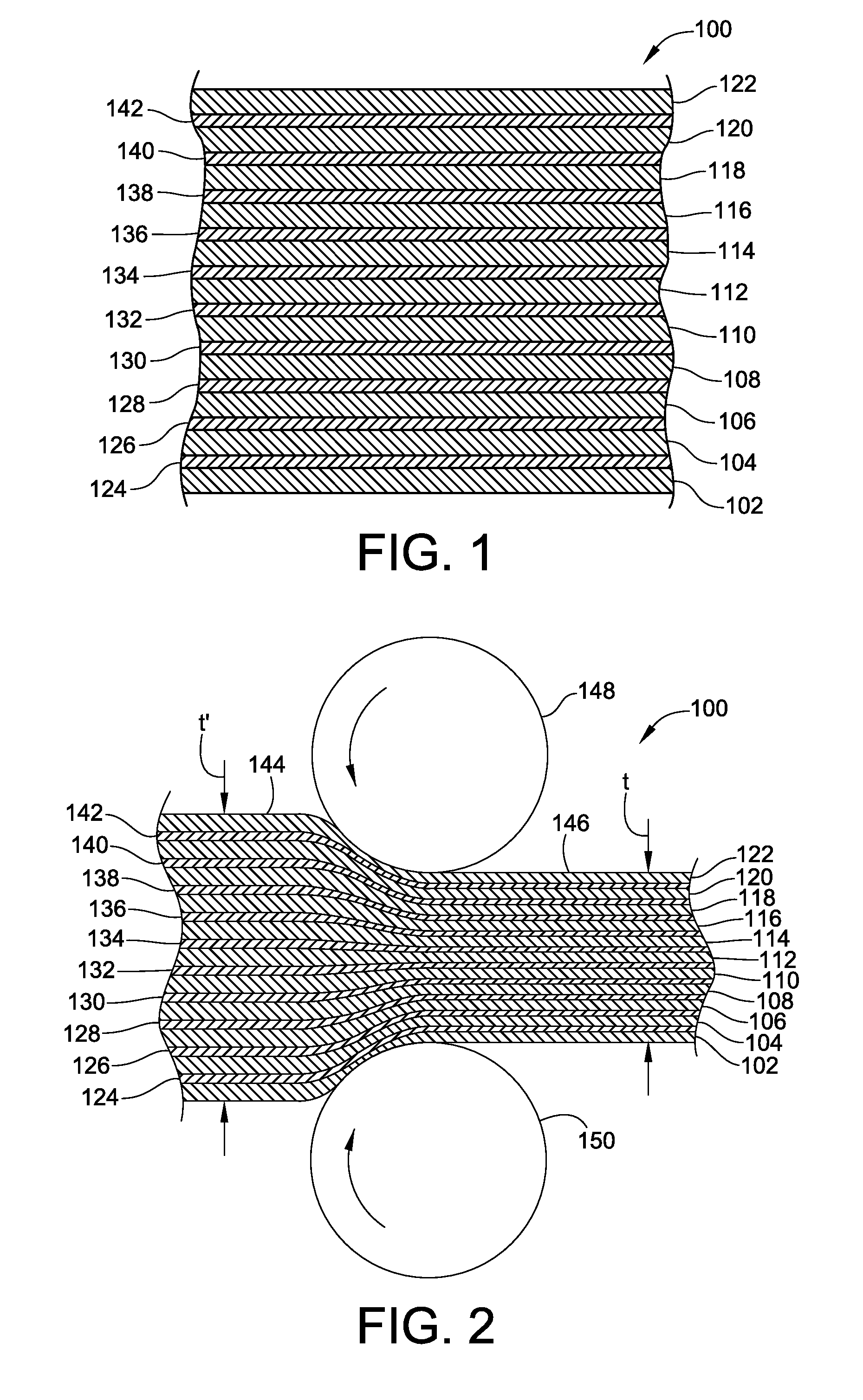

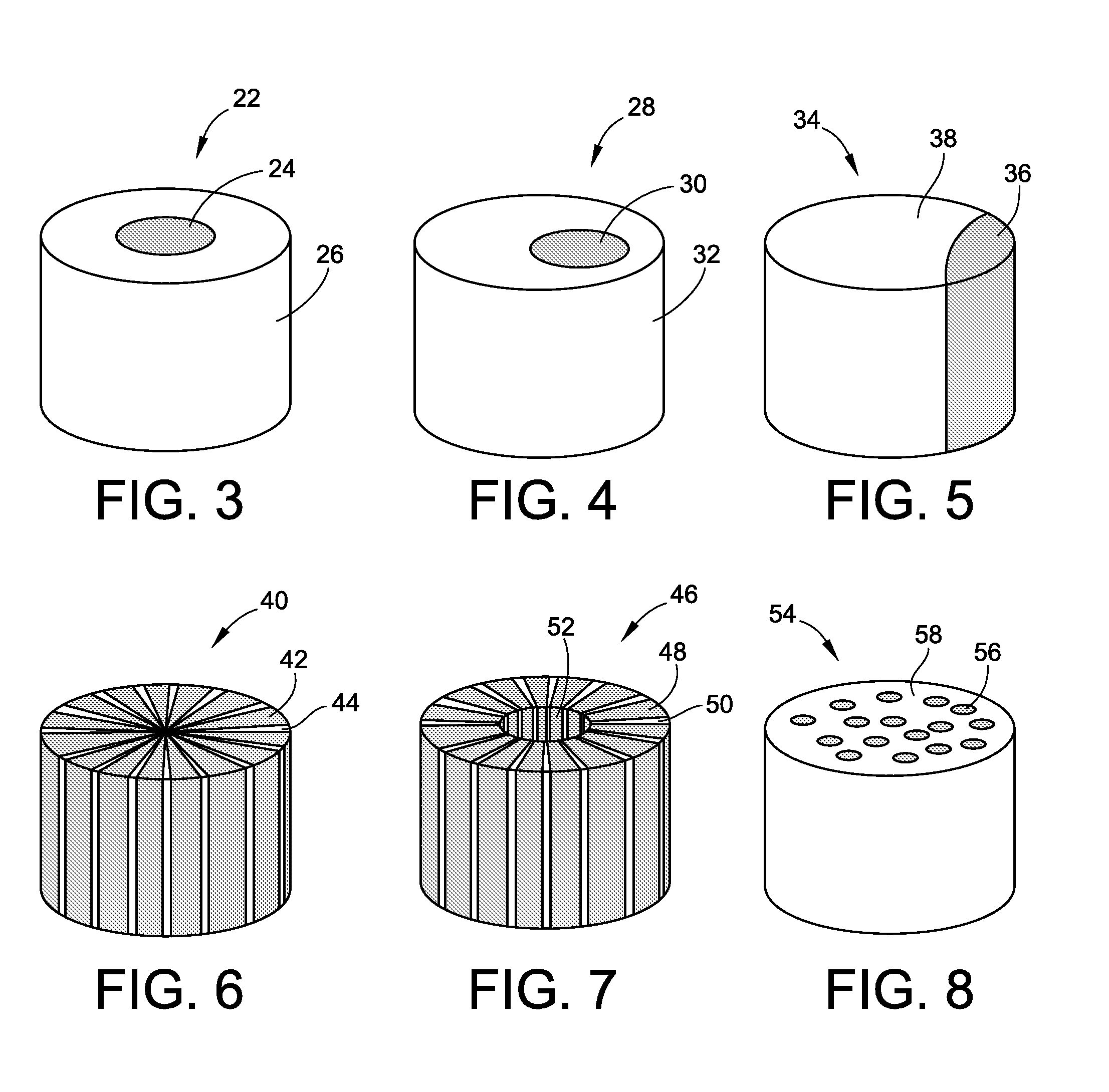

Compressed nanofiber composite media

a composite media and nanofiber technology, applied in the field of filter media, can solve the problems of engine damage, engine injector damage, engine flame-out,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]Prior to turning to the details, some lexicography will be developed to assist in understanding the present invention. As used herein, the term “substrate” is meant to be broad in nature and meant to include any structure upon which fine fibers are carried or deposited. “Substrate” may include conventional formed filter medias such as scrims and the like that may be unwound from media rolls. Such filter medias have a fiber entanglement that typically bonded or secured together mechanically, chemically, adhesively and / or otherwise and thereby have strength such that they cannot be easily torn manually (e.g. a 1 square foot sheet typically holds up to application of tension of 5 lbs force) and have filtrations properties. “Substrate” may also include looser fiber entanglements that may not be bonded together or secured together (e.g. a 1 square foot sheet may fall apart upon application of tension of 5 lbs force). A “scrim” used as herein refers to woven or non-woven fiber entan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com