Radiator fin and radiator fin component thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Below, the preferred embodiments of the present invention are described in detail incorporating the drawings.

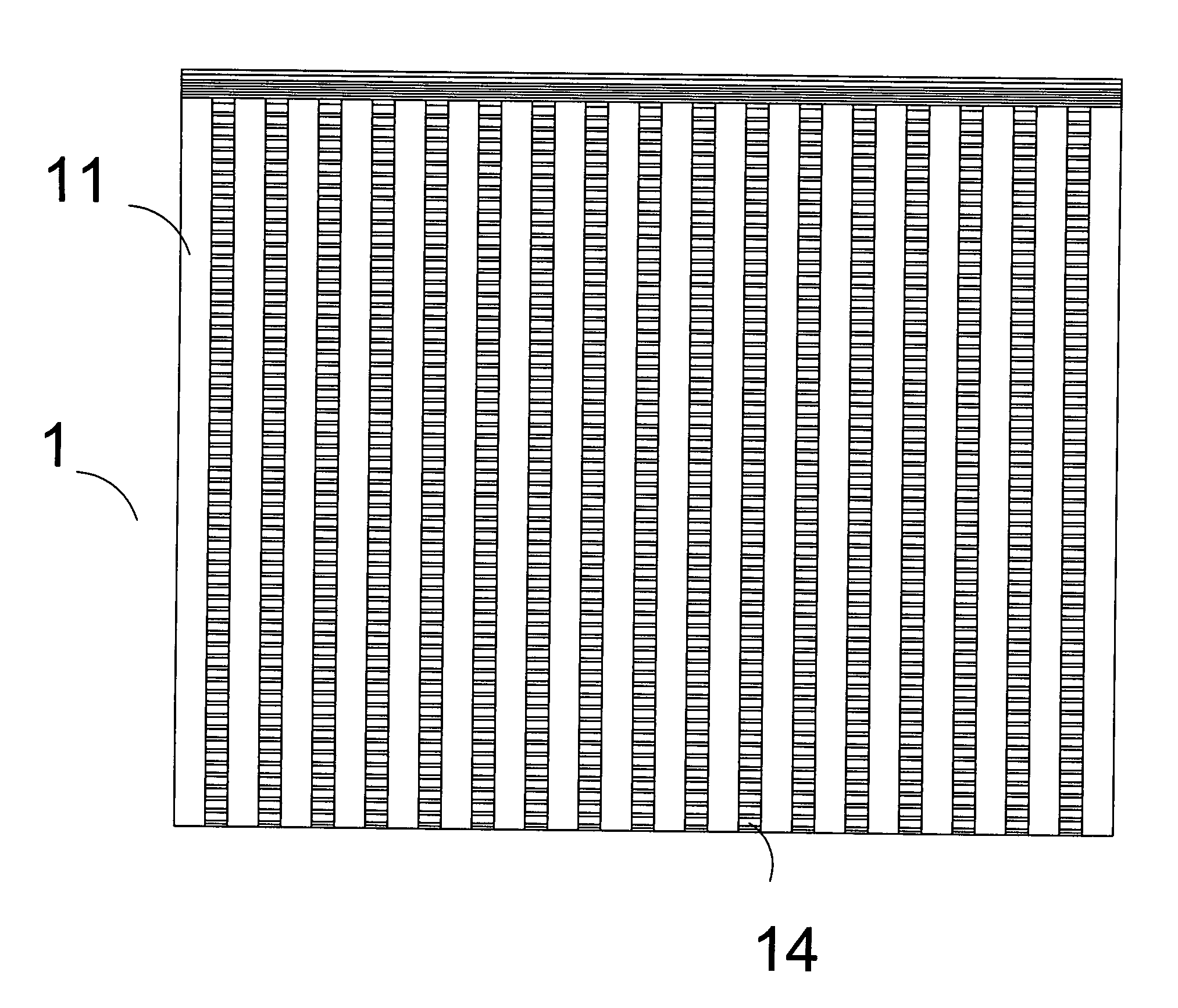

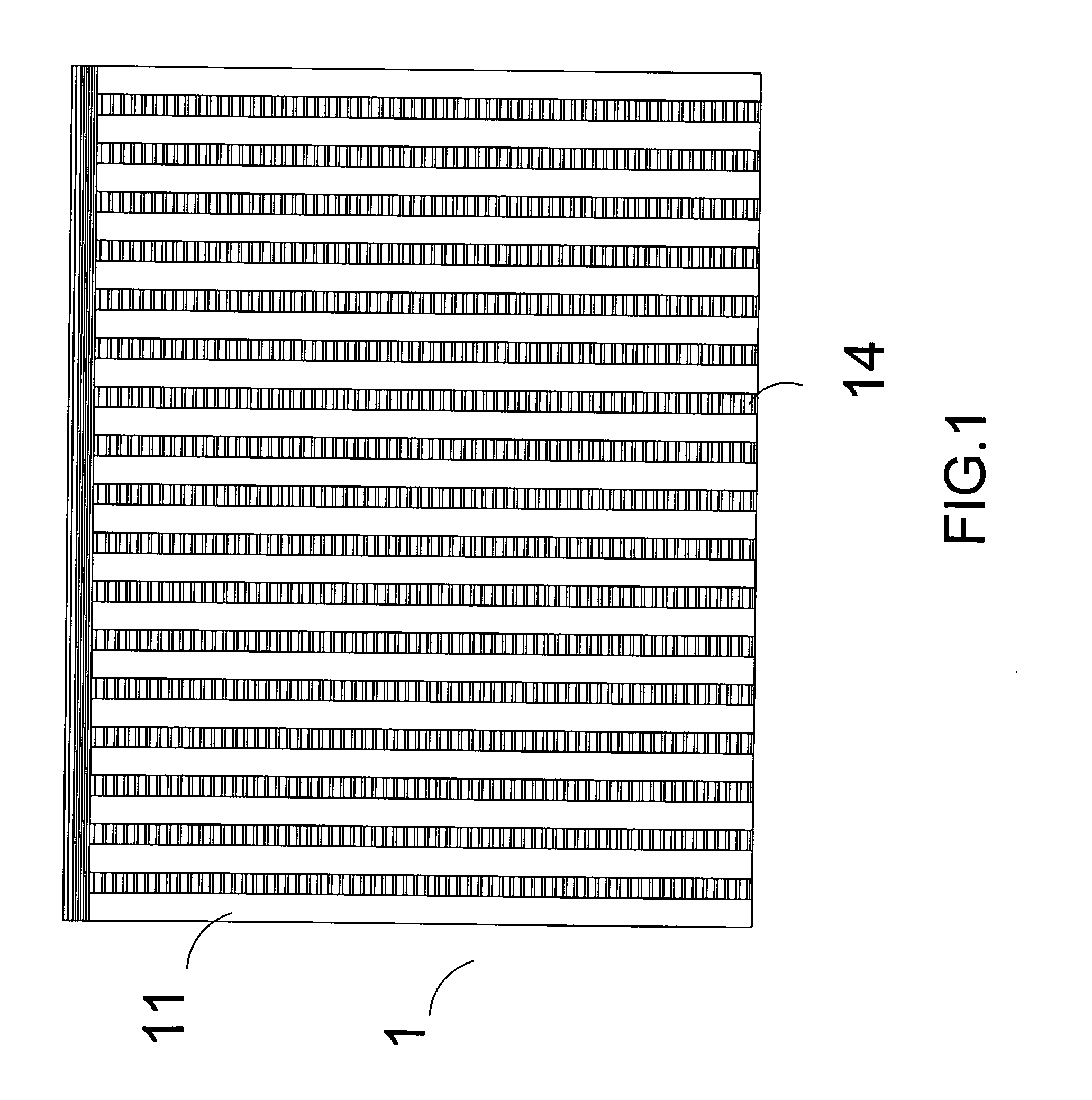

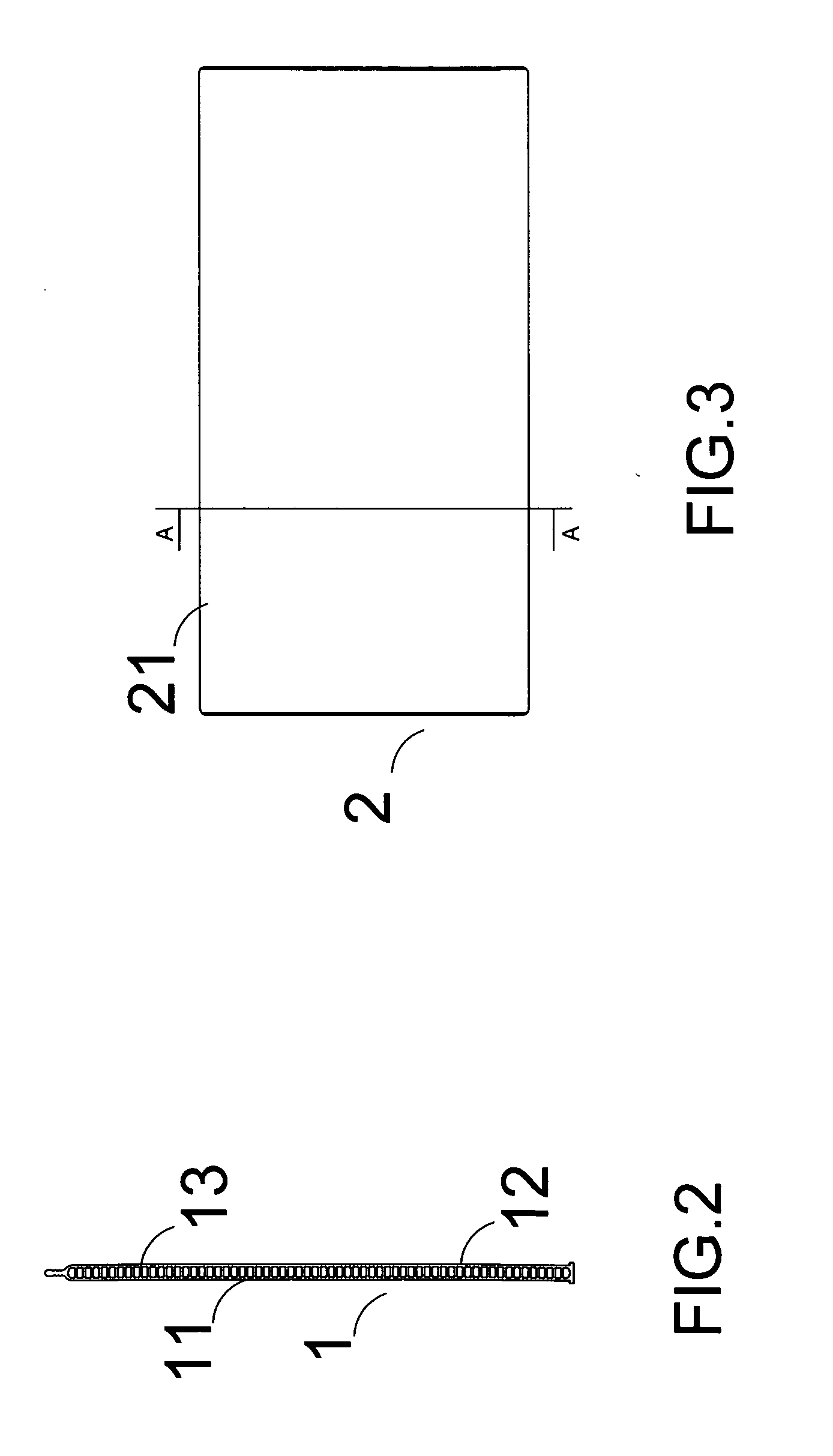

[0026]Referring to FIG. 1 to FIG. 2 of the drawings, a radiator fin according to the first preferred embodiment of the present invention is illustrated. The radiator fin comprises two heat conducting vanes 11, 12 which are joined end to end and top to top, and the two heat conducting vanes 11, 12 are made of aluminum or other materials which possess a high coefficient of heat conduction and multiple strength vanes 13 next to inner walls of the heat conducting vanes 11, 12 are provided in the space between the two heat conducting vanes. The two heat conducting vanes 11, 12 and the strength vanes 13 are all in porous structure. Further, the two heat conducting vanes 11, 12 provide allowing ventilation regions correspondingly, and the allowing ventilation regions are breather holes or continuing breather grooves 14 correspondingly provided in the heat conducting vanes. Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com