Energy recovering system for an internal combustion engine

a technology of energy recovery and internal combustion engine, which is applied in the direction of engines, machines/engines, mechanical equipment, etc., can solve the problems of unrecoverable additional heat or energy sources, unusable energy content of known engines, and worse global energy balance, etc., to achieve the effect of reducing backpressure on the main exhaust line, reducing thickness, and reducing volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

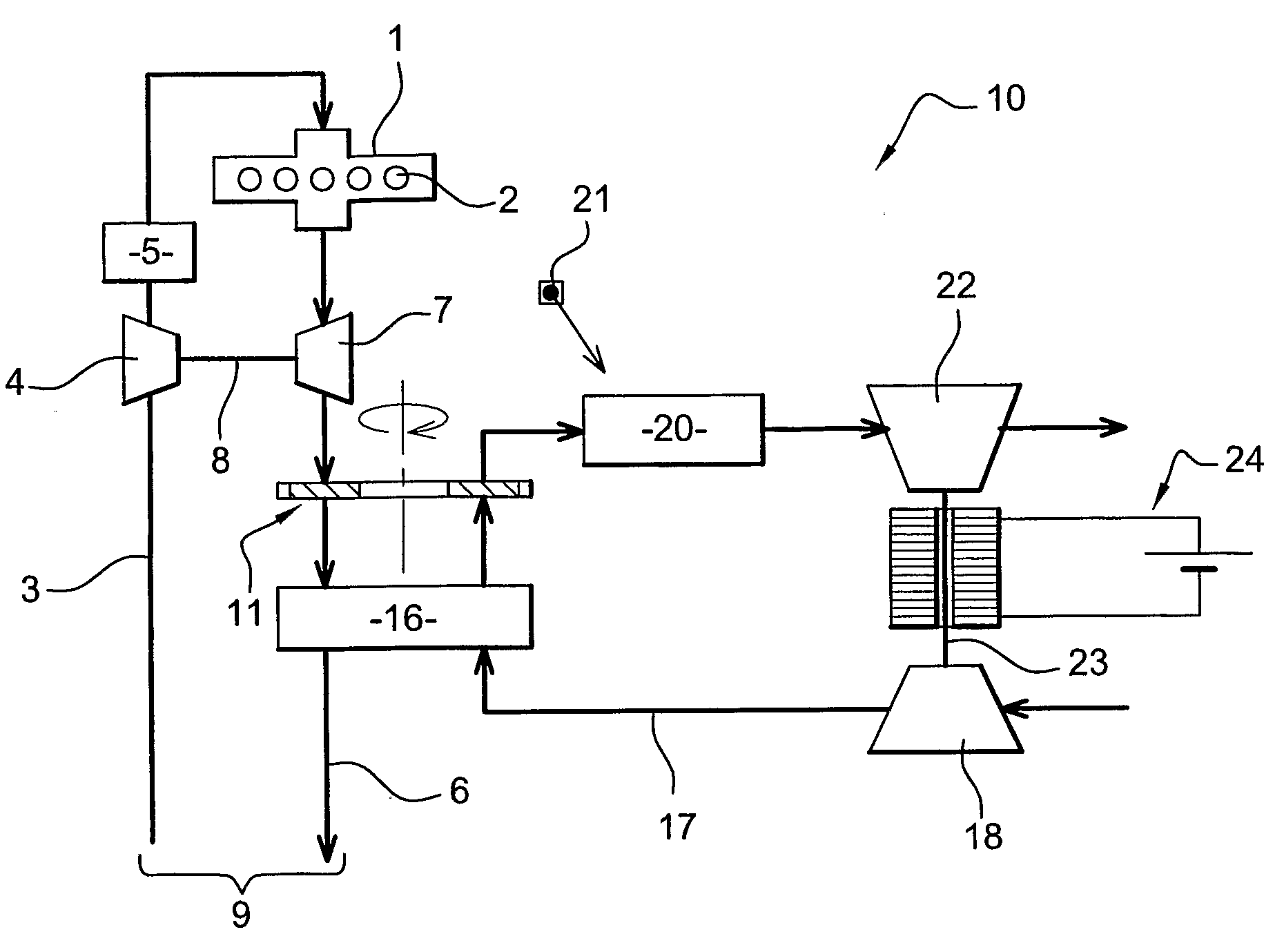

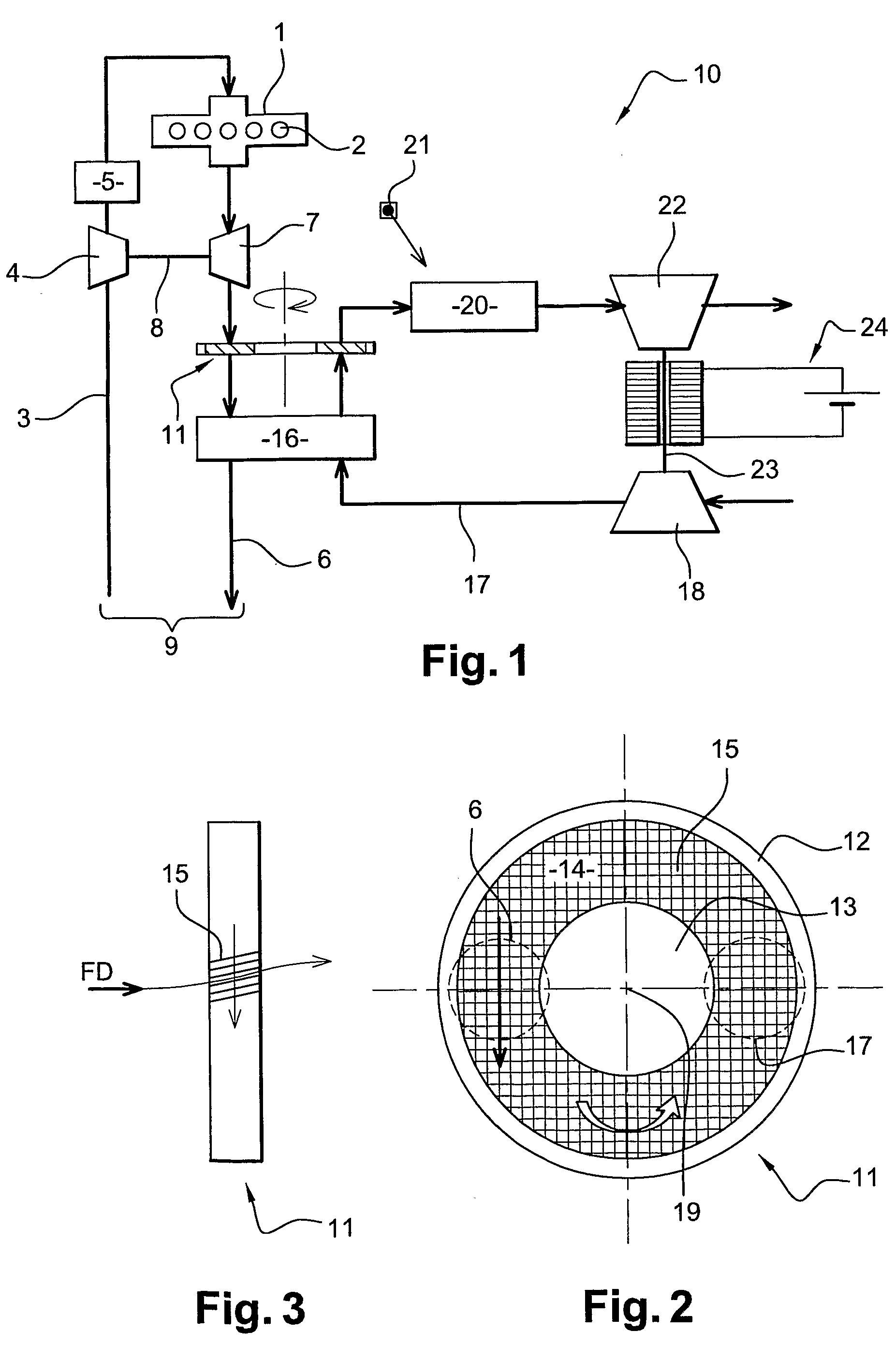

[0040]As depicted in FIG. 1, an internal combustion engine typically comprises an engine block 1 defining a plurality of cylinders 2, namely six cylinders in the illustrated embodiment. The engine is for example a diesel engine. However the invention may concern any type of internal combustion engine needing a particle filter to meet ongoing or future legislation limits.

[0041]Intake air is carried towards an intake manifold feeding the cylinders 2 through an air intake line 3. Air intake line 3 can include a compressor 4 and an air intake cooler 5 located downstream from said compressor 4.

[0042]Exhaust gas formed in each cylinder 2 is collected by an exhaust manifold and then carried through an exhaust line 6 towards the atmosphere. The exhaust line 6 can suitably comprise a turbine 7 driven by the exhaust gas, said turbine 7 being mechanically connected to compressor 4 by means of a shaft 8.

[0043]Intake line 3 and exhaust line 6 define a main line 9 of an energy recovering system 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com