Very large mode slab-coupled optical waveguide laser and amplifier

a laser and amplifier technology, applied in the field of very large mode slab coupling optical waveguide lasers, can solve the problems of limiting the power in a single mode, affecting the performance of the amplifier, and becoming more difficult to provide sufficient gain to the fundamental mode,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]The invention provides a novel design for a VLM SCOWL to increase its single spatial mode output power. Increasing the output power of the SCOWL is accomplished by an increase of the optical mode size of the fundamental SCOWL mode.

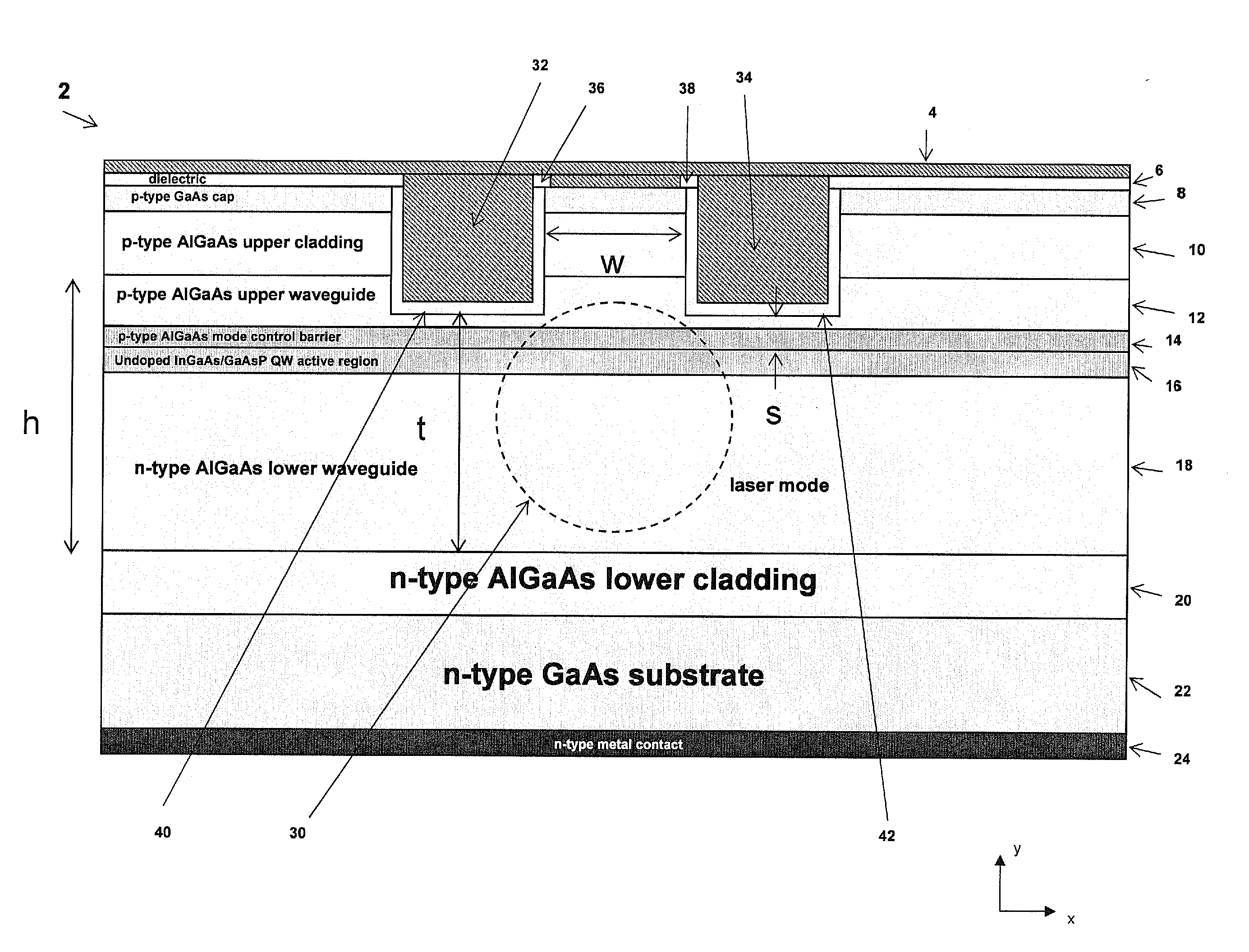

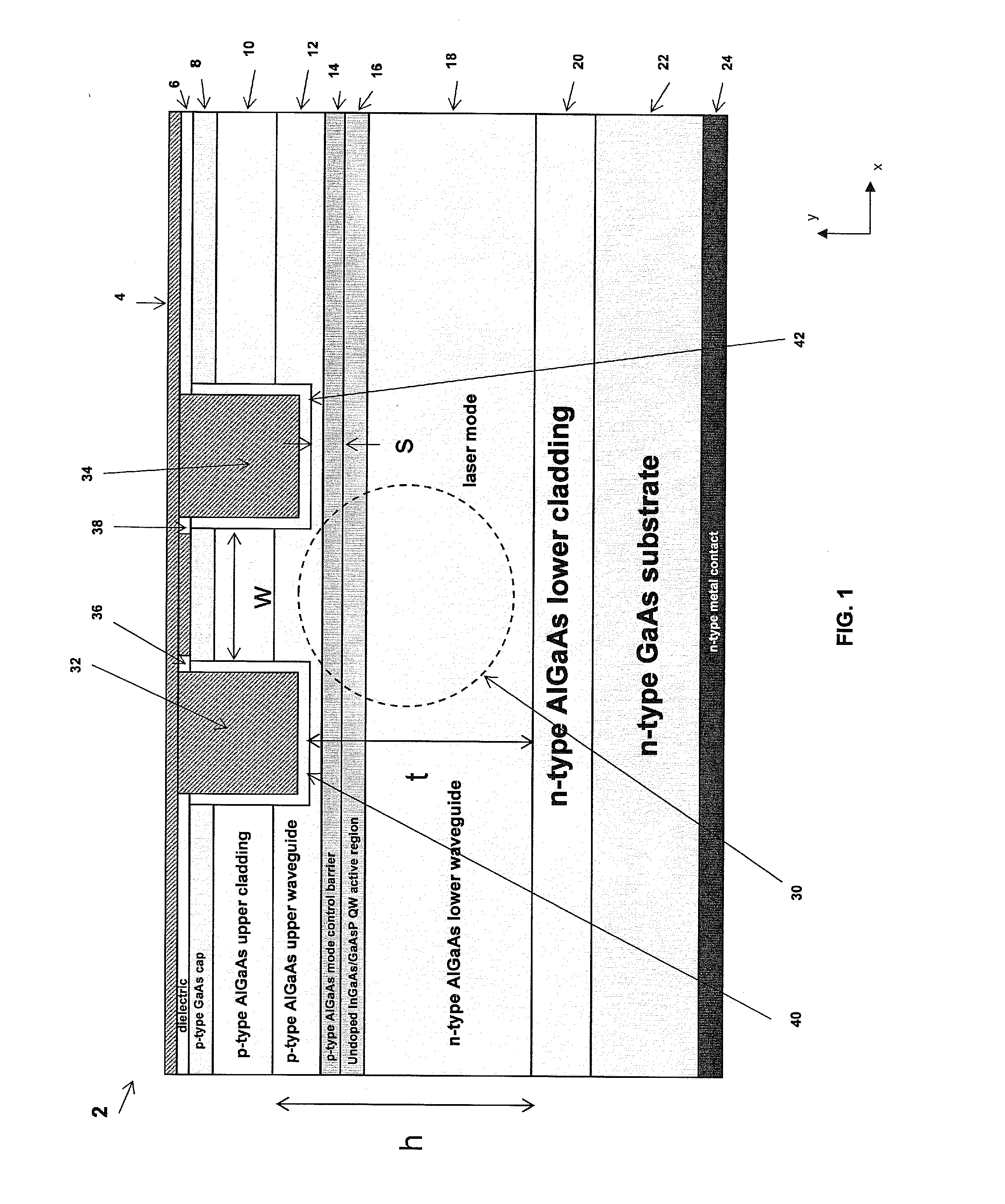

[0015]FIG. 1 shows a cross-sectional view of a VLM SCOWL 2 formed in accordance of the invention. The VLM SCOWL 2 includes a p-type metal layer 4 positioned on a dielectric layer being 6. The dielectric layer 6 is positioned on a p-type GaAs cap layer 8. The VLM SCOWL 2 also includes a p-type upper cladding layer 10 where the p-type GaAs cap layer 8 is positioned on. The p-type upper cladding layer 10 is formed on a p-type AlGaAs upper waveguide region 12. A p-type mode control barrier layer 14 is positioned between the p-type upper waveguide region 12 and an undoped active region 16. The undoped active region 16 is placed on an n-type lower waveguide region 18. The n-type lower waveguide region 18 is positioned on an n-type lower cladding layer 20.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com