Coupling

a technology of coupling and sealing surface, applied in the direction of sleeve/socket joint, non-disconnectible pipe-joint, joints with sealing surfaces, etc., can solve the problems of reducing the corrosion resistance of surfaces, adding to the assembly time, and leaking paths with these fittings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

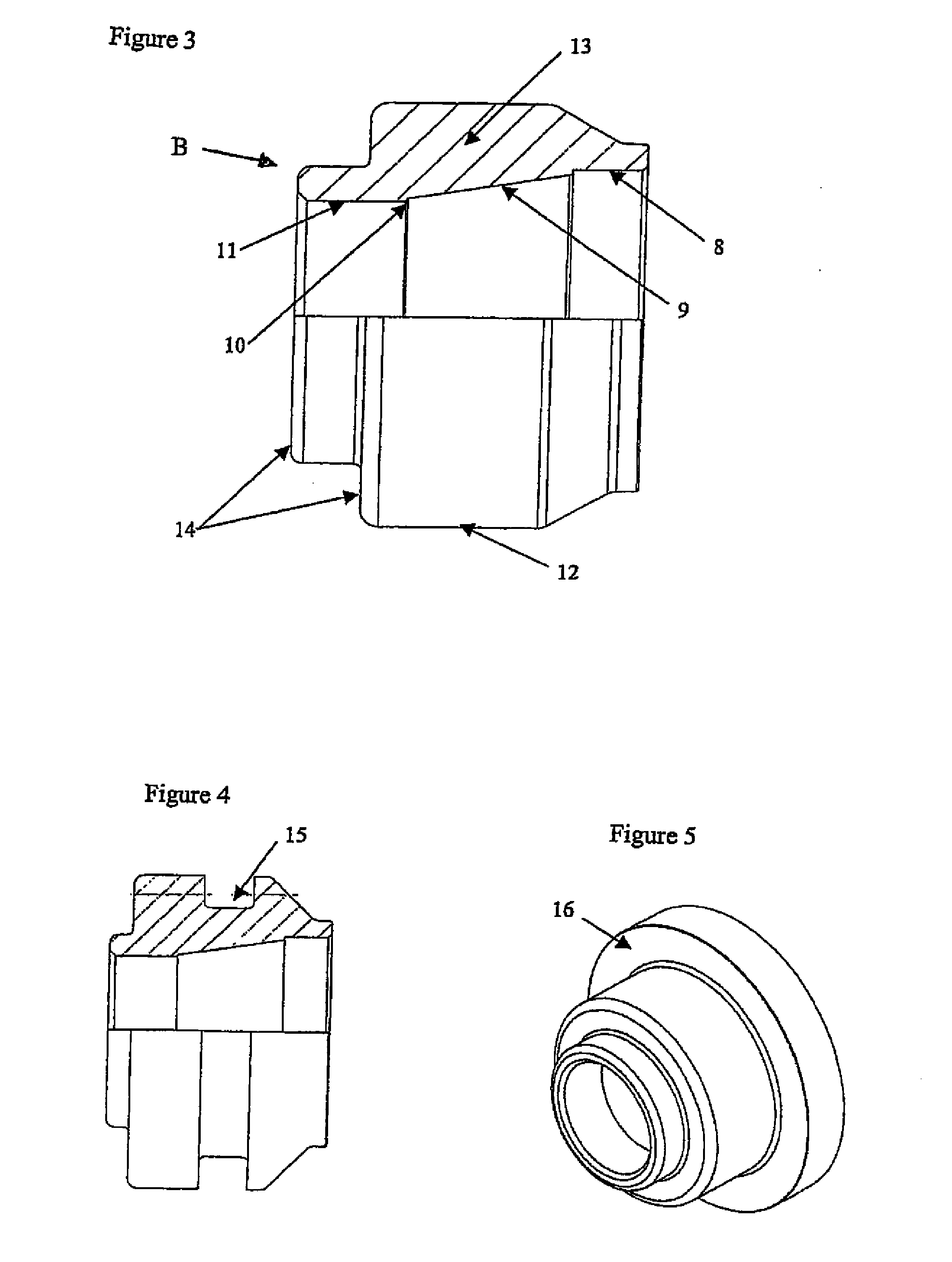

[0044]The following examples discuss the invention being used in conjunction with a traditional tube. However the invention can also be used with a pipe, solid rod, wire rod or any other round section.

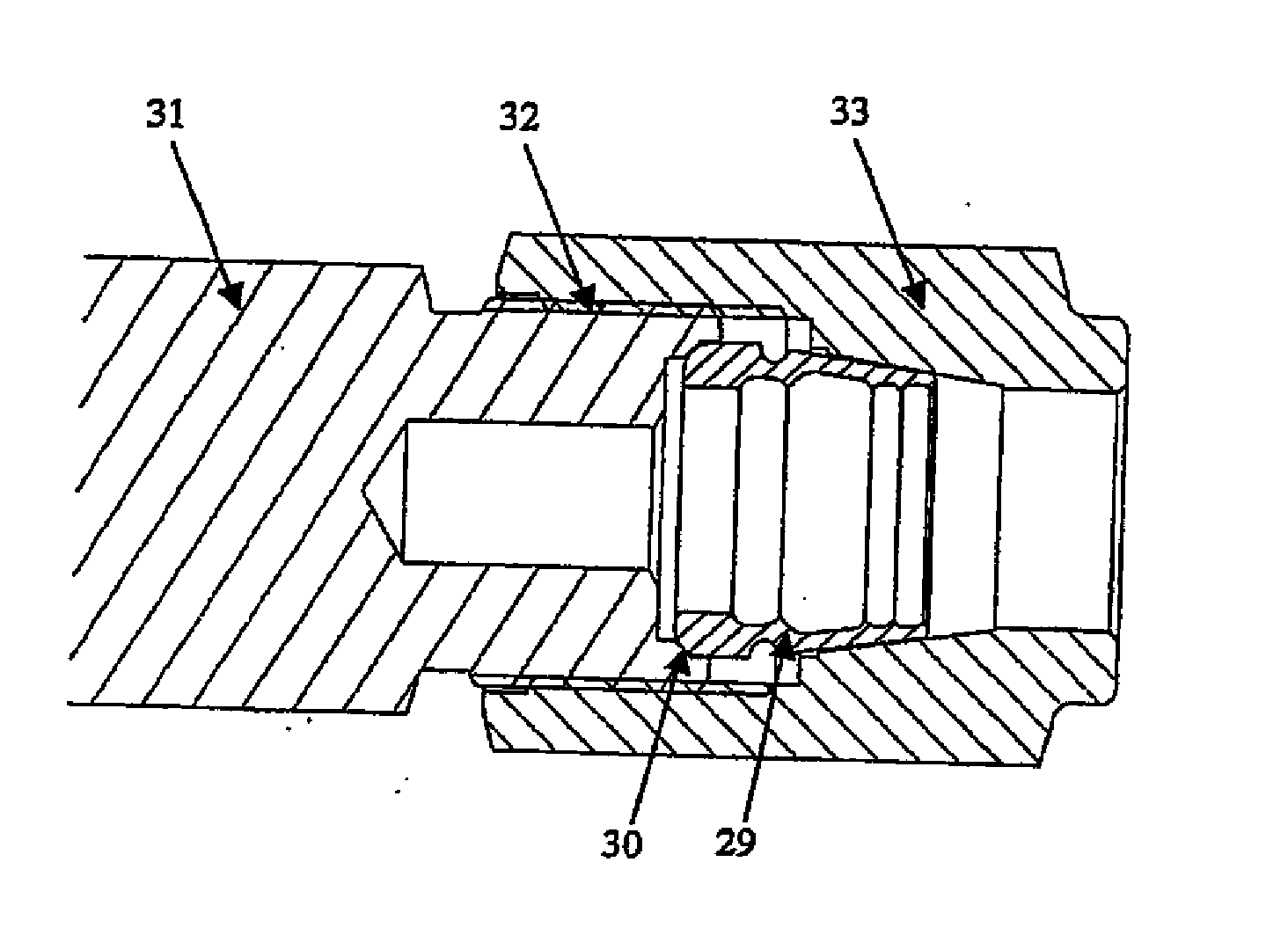

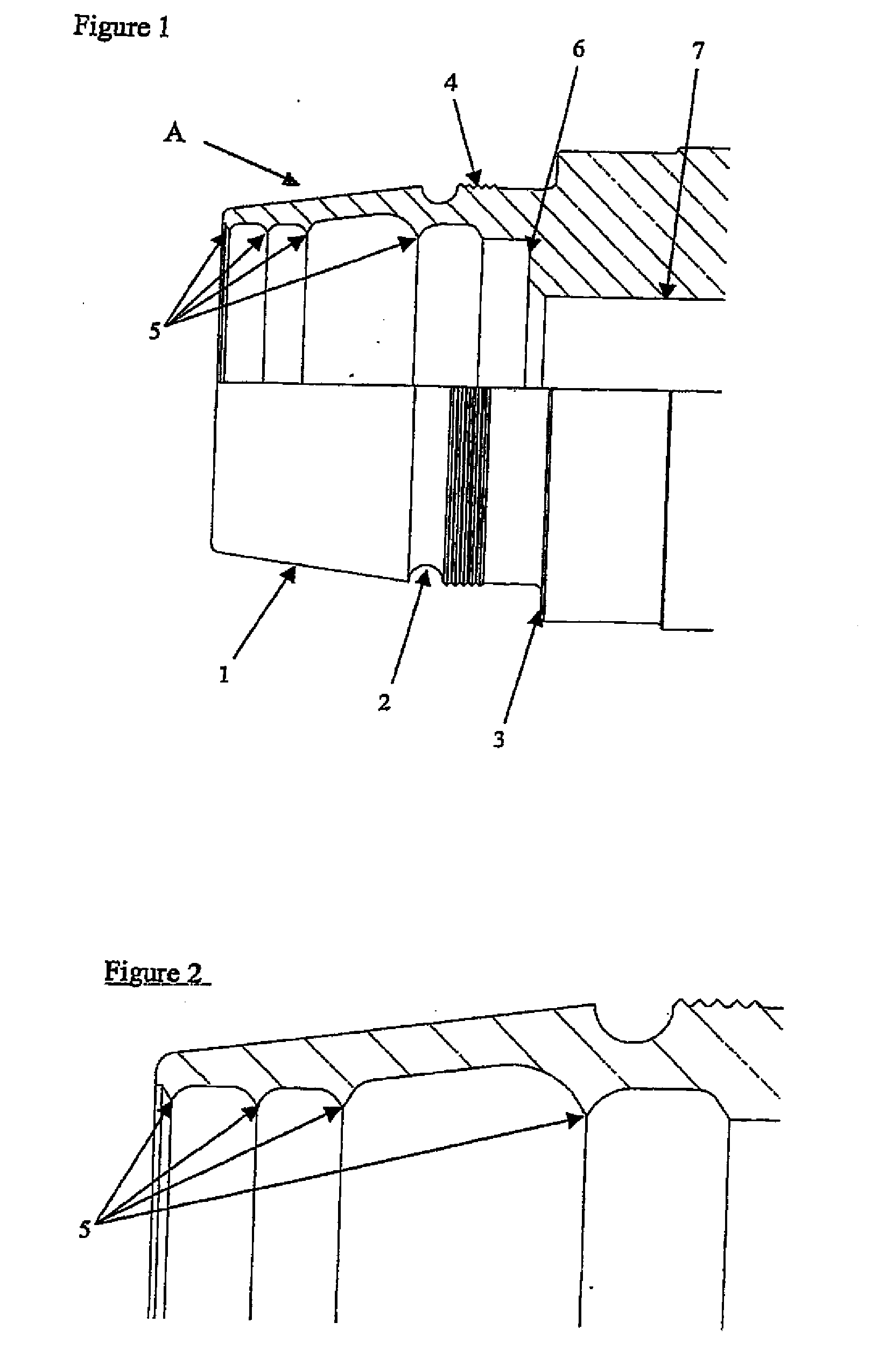

[0045]Embodiments of the invention include a method of attaching a coupling and a coupling that can for example, be machined into a traditional coupling, as will be shown in the following example, or machined onto existing equipment such as, but not limited to, valves, manifolds, pumps, hoses etc. The coupling comprises an inner body or a sealing member as shown for example in FIGS. 1 and 2 and a separate section or collar as shown for example in FIG. 3, which is used to modify the form of the sealing member.

[0046]The sealing member seals against a tube and also retains the tube in position. This member will be referred to as the claw end in the following description and is shown in FIGS. 1 and 2.

[0047]In this example the claw end A has an outside surface with an external frusto-cone 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| radii | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com