Strip edge shape control apparatus and method in strip casting process

a strip casting and control apparatus technology, applied in the direction of manufacturing tools, foundation moulding apparatus, melt-holding vessels, etc., can solve the problems of high roll force, deterioration of the quality of the side, and non-solidification of molten steel and strip breakdown, so as to prolong the life of the edge dam, suppress the generation of strip scraps, and improve the quality and productivity of the strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

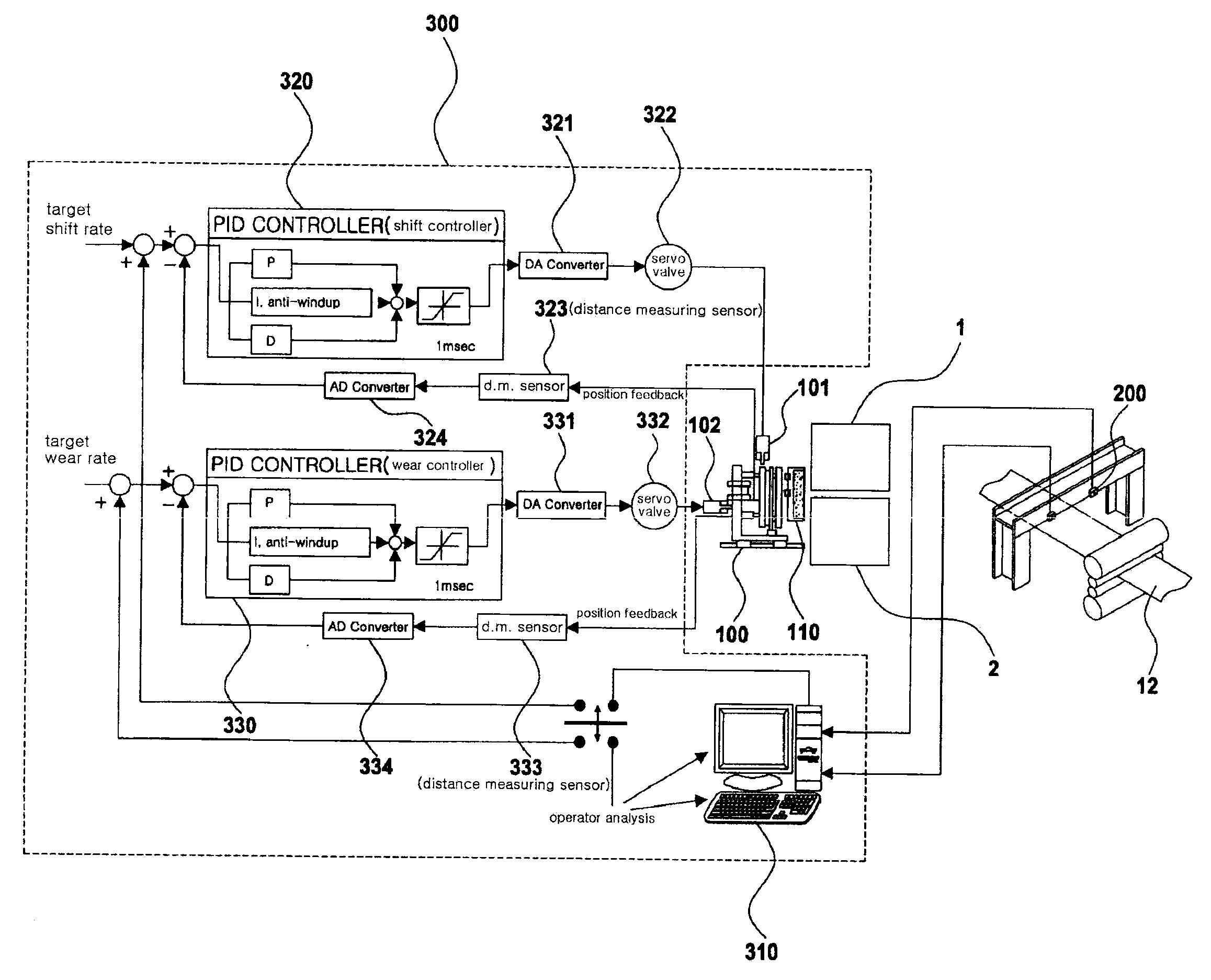

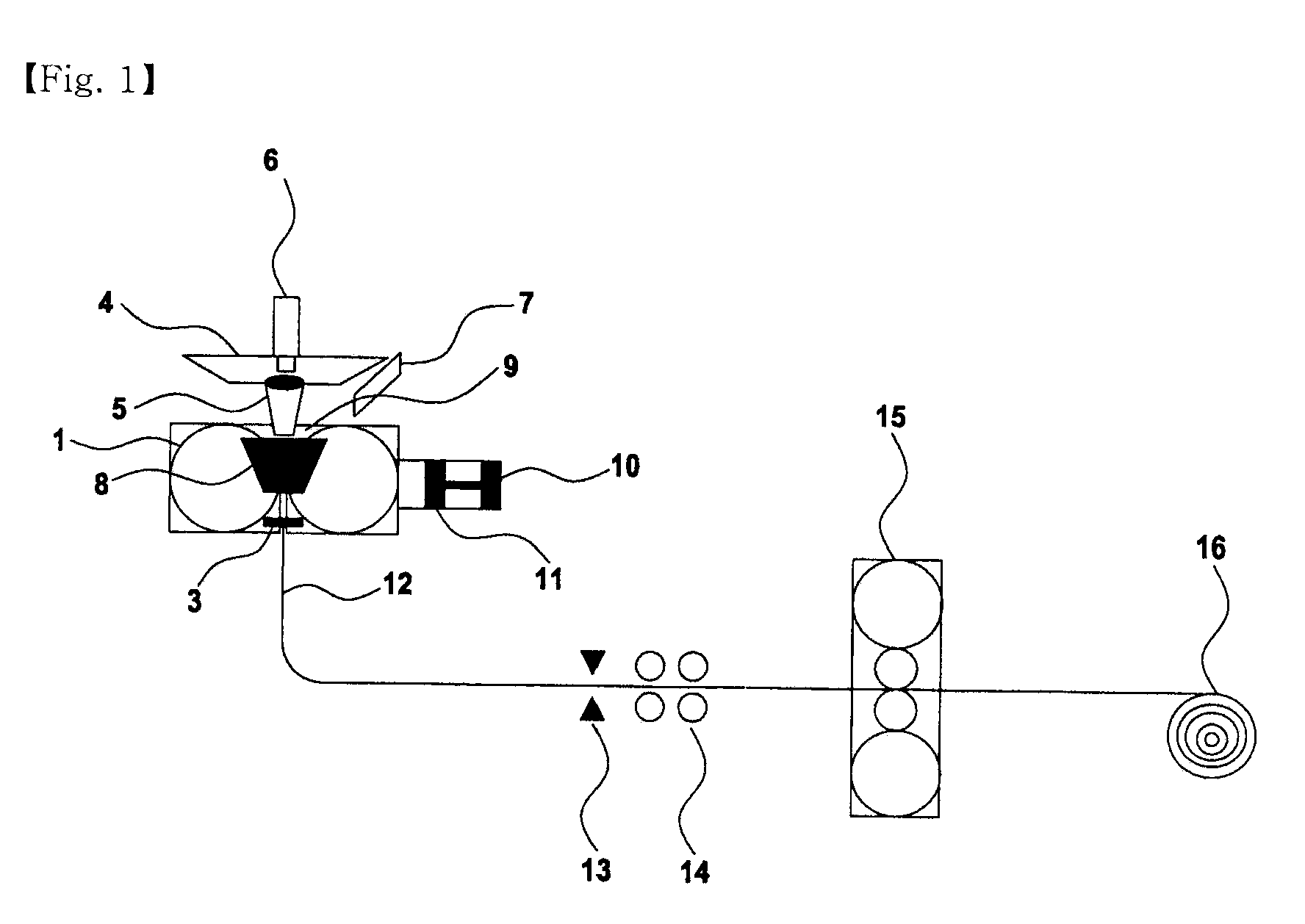

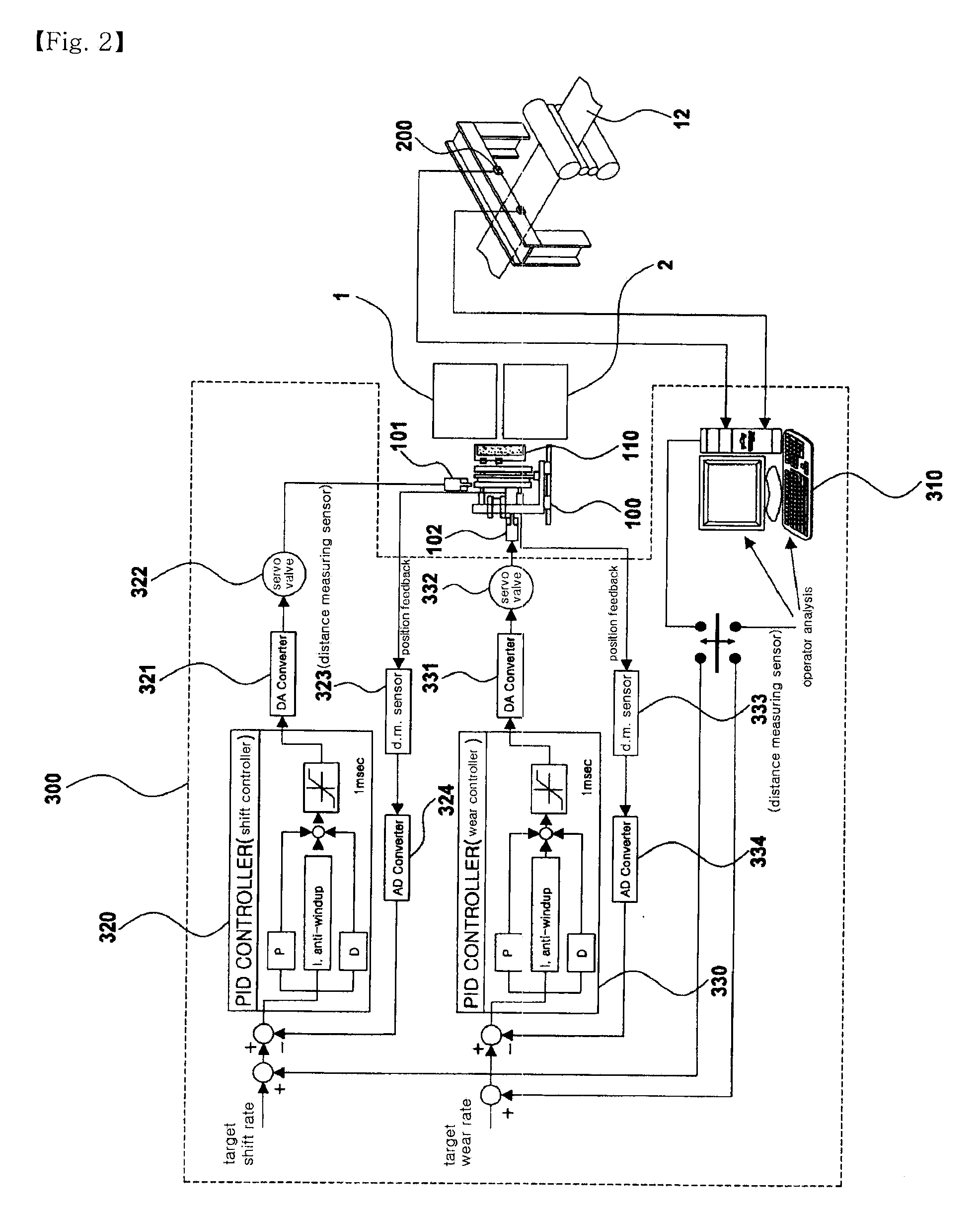

[0031]FIG. 2 is a block diagram showing the construction of an apparatus for controlling the edge shape of a strip in a twin-roll strip casting process (hereinafter referred to as “edge shape control apparatus”) according to an embodiment of the present invention, and FIG. 3 is a view showing the position of cylinders attached to an edge dam.

[0032]As shown in FIG. 2, the edge shape control apparatus comprises an edge dam driving unit 100 which is attached to both sides of casting rolls so as to control the pressing force of the edge dams against the casting rolls and the upward shift of the edge dams depending on the wear and upward shift rate of the edge dams; cameras 200 which are disposed at both sides of the edge dams at the outlet side of the casting rolls 12 through which a strip 12 is discharged, the cameras serving to photograph the edge portion of the strip; and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com