Evaporative pre-cooler for air cooled heat exchangers

a technology of pre-cooler, which is applied in the field of evaporative coolers, can solve the problems of large air cooled heat exchangers with multiple independently staged fans, high complexity and variable air flow of evaporative pre-coolers, and monoblock pre-cooler systems cannot adapt, so as to improve the efficiency of power plants, reduce the temperature of combustion air, and enhance the effect of power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

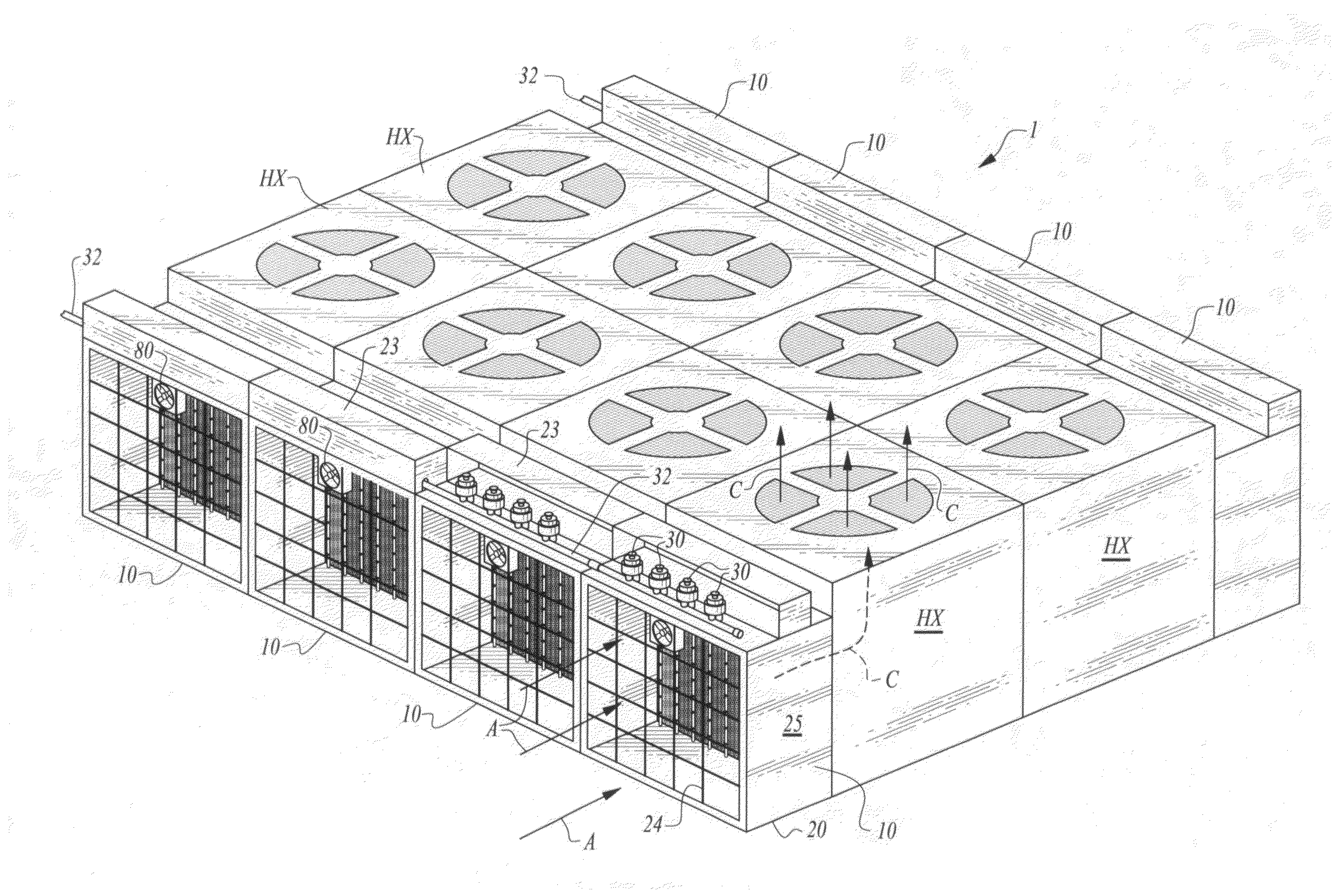

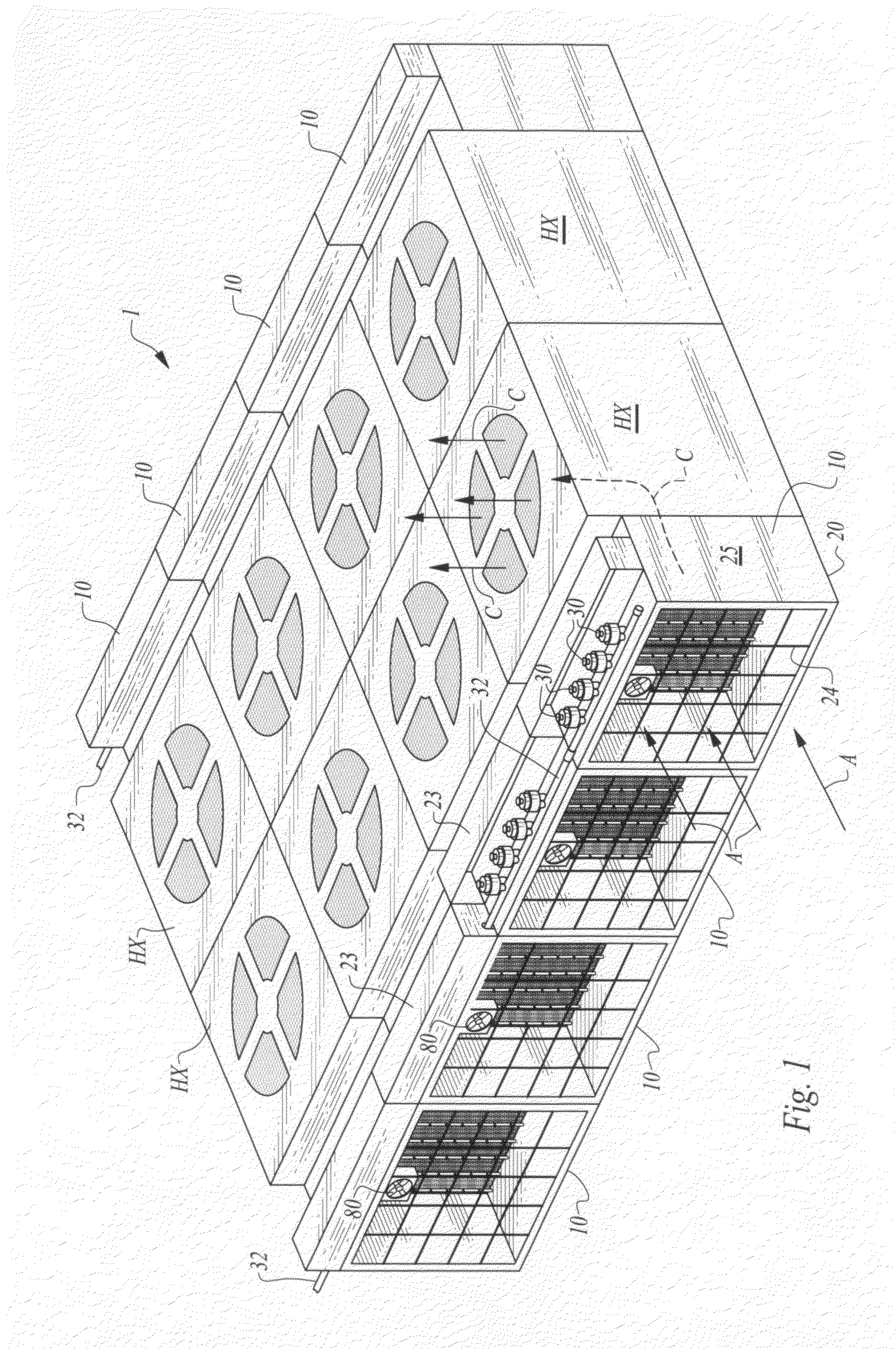

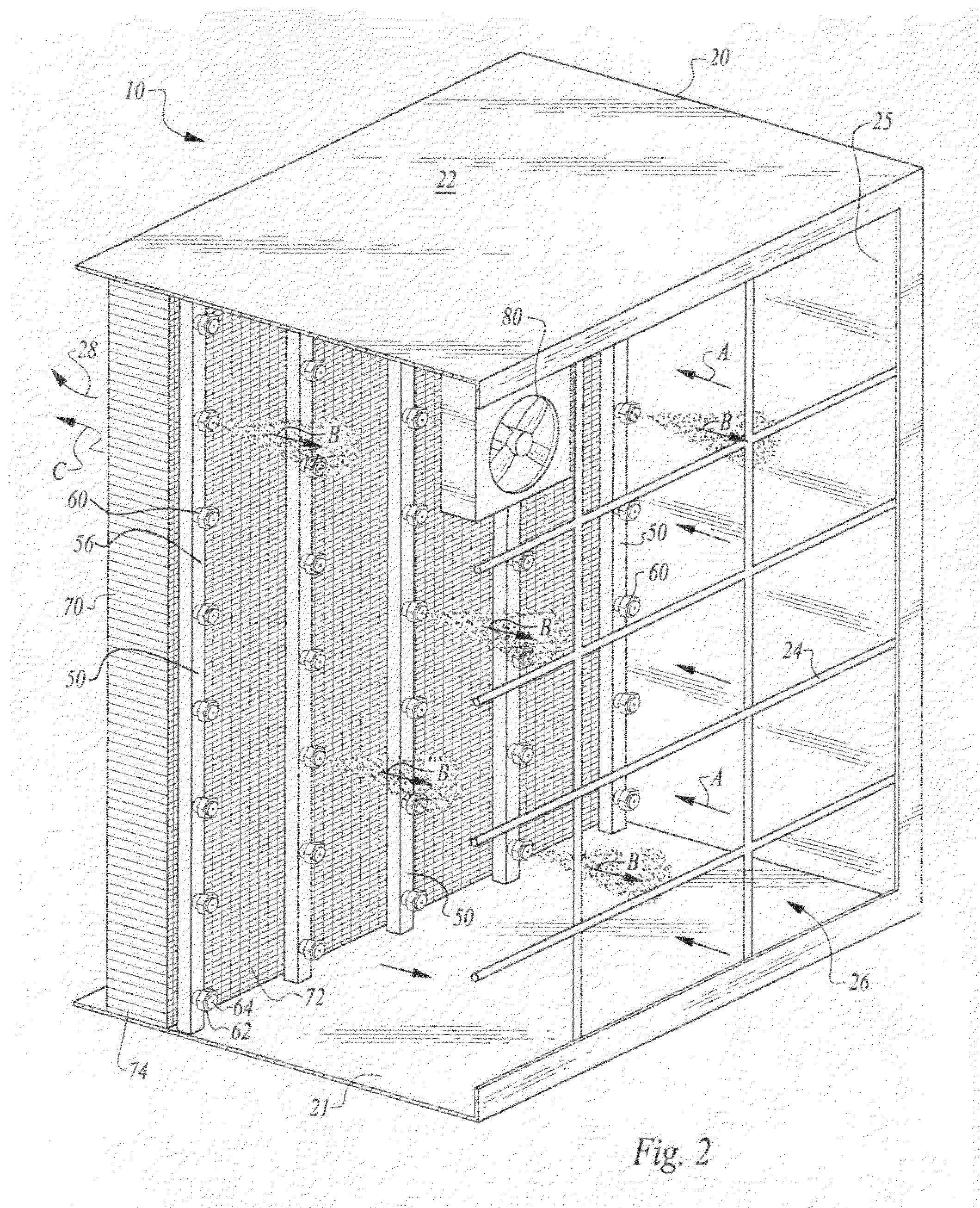

[0041]Referring to the drawings, wherein like reference numerals represent like parts throughout the various drawing figures, reference numeral 10 is directed to a pre-cooler cell (FIGS. 1 and 2) for use alone or together adjacent a heat exchanger HX or system 1 of multiple heat exchangers HX to pre-cool air (arrow A of FIG. 1) entering the heat exchangers HX. The pre-cooler 10 evaporates water into the air to reduce a temperature of the air and increase a mass of the air for enhanced effectiveness of the heat exchanger HX. The cells 10 are configured to have a precise and highly adjustable water flow rate while maintaining a fine spray of water for consistent evaporative effectiveness, maximizing air temperature reduction while avoiding water droplet carryover downstream.

[0042]In essence, and with particular reference to FIG. 2, basic details of the pre-cooler cell 10 of this invention are described, according to a most preferred embodiment. The cell 10 includes a housing 20 as a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com