Novel multi-analyte optical computing system

a multi-analyte, optical computing technology, applied in the direction of optical radiation measurement, instruments, spectrometry/spectrophotometry/monochromators, etc., can solve the problems of inability to accurately measure one's data, inability to convert simple light intensity measurement to information, and inability to accurately estimate the accuracy of one's data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example i

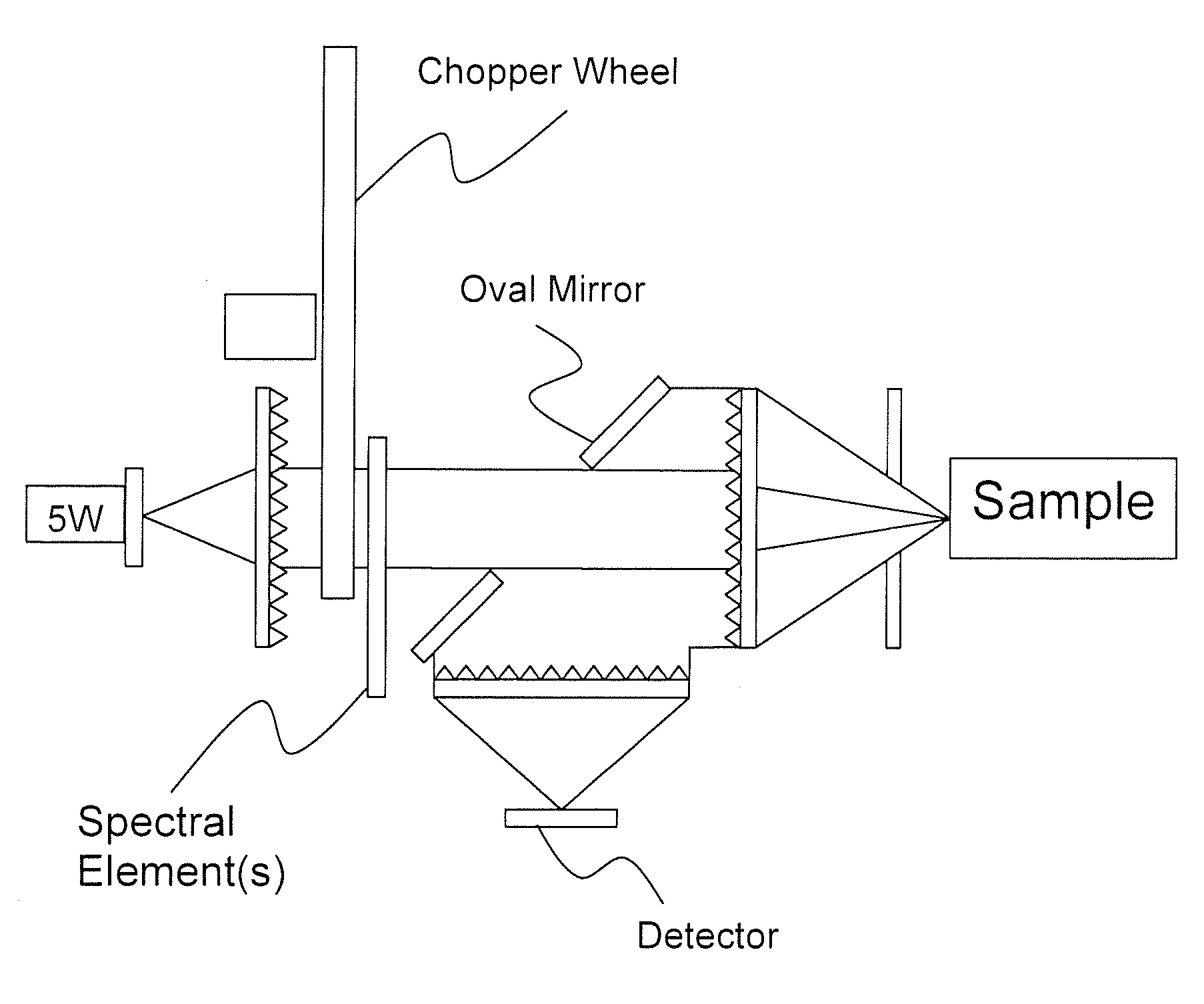

[0084]System I: A first breadboard system was constructed and used to test a mixture of powders. System I components included:

[0085]Illumination: 20 W Gilway lamp

[0086]Spectral elements: 5 mm deuterium oxide (D2O), 5 mm Germanium

[0087]Optical window: fiber optic probe

[0088]Detector: InAr detector from Judson

[0089]MOE: specific to test

[0090]Procedure and Results of static testing using System I: A powdered sample with a known composition was placed in a dish and the fiber optic probe was placed in contact with the powder. The output of the detectors was monitored and recorded.

example ii

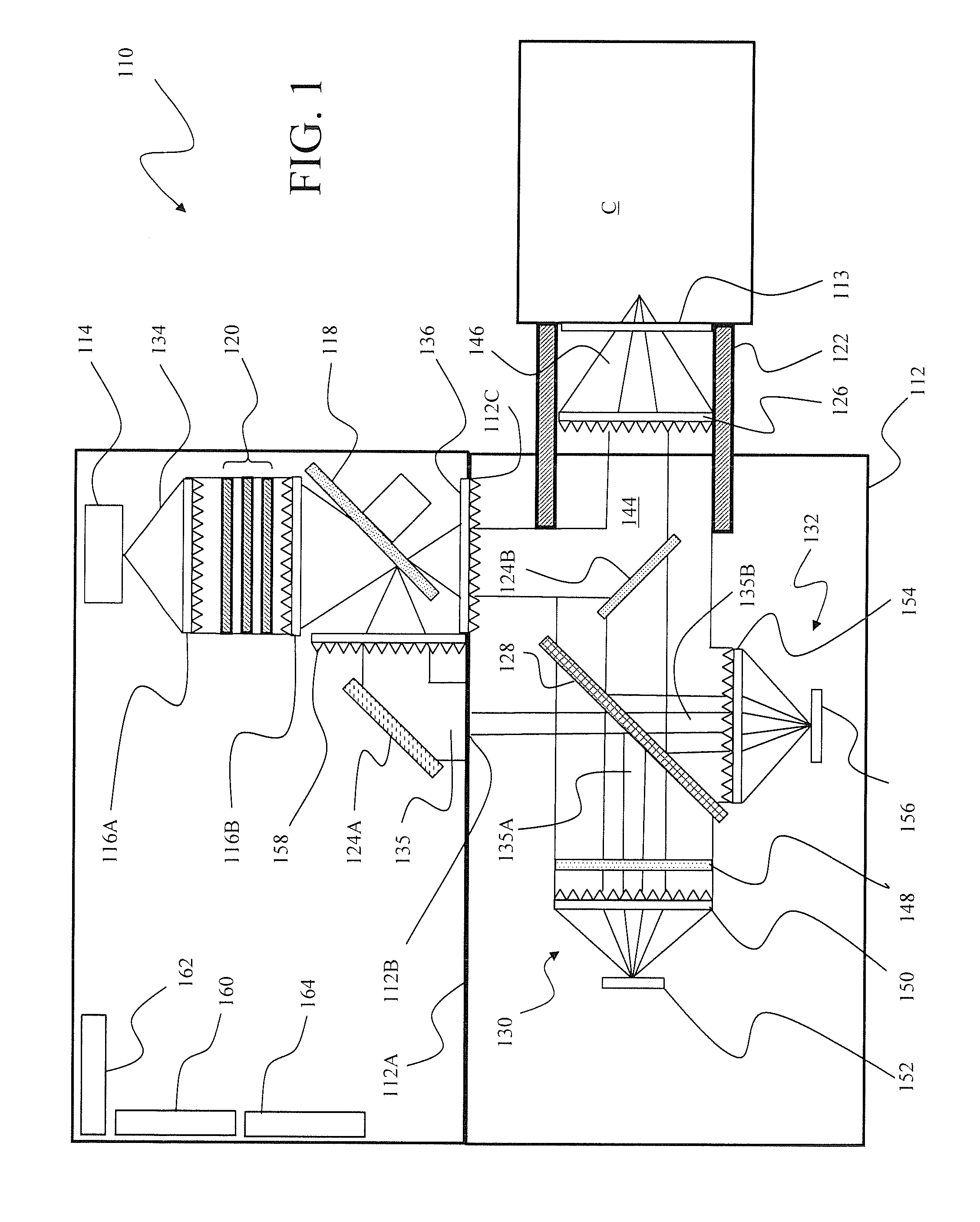

[0091]System II: A system similar to the optical analysis system 110 shown in the figures was constructed and used to make static measurements on aspirin / lactose. System II components included:

[0092]Illumination: 20 W Gilway lamp

[0093]Spectral elements: 5 mm D2O, 5 mm Germanium

[0094]Optical window: none

[0095]Detector: PbS detector from New England Photoconductor

[0096]MOE: specific to test conditions.

[0097]Procedure and Results of static testing using System II: A powdered sample with a known composition was placed in a dish and the system light beam was focused on the powder. The output of the detectors was monitored and recorded. Aspirin / lactose samples covering the range of 100% aspirin to 100% lactose were tested.

example iii

[0098]System III: A system similar to the optical analysis system 110 shown in the figures was constructed and used to make dynamic measurements on aspirin / lactose. System III components included:

[0099]Illumination: 20 W Gilway lamp

[0100]Spectral elements: 5 mm D2O, 5 mm Germanium

[0101]Optical window: sapphire window

[0102]Detector: PbS detector from New England Photoconductor

[0103]MOE: specific to test conditions.

[0104]Procedure and Results of dynamic testing using System III: The Aspirin / Lactose testing was made on a mixer bowl containing lactose and the system measured as aspirin was added to the system and mixed. Specifically, lactose powder was placed in the bowl of a mixer and the measurement system was attached the bowl using a Swagelok® brand fitting. A sapphire window was used to contain the powder in the bowl and allow the system to interrogate the powder. With the mixer turning, known amounts of aspirin were added and the system output signal was monitored and recorded. As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com