Self contained water-to-water heat pump

a heat pump and self-contained technology, applied in heat pumps, lighting and heating apparatus, heating types, etc., to achieve the effect of preventing coolant freezing, reducing the cost of implementation, and reducing the cost of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

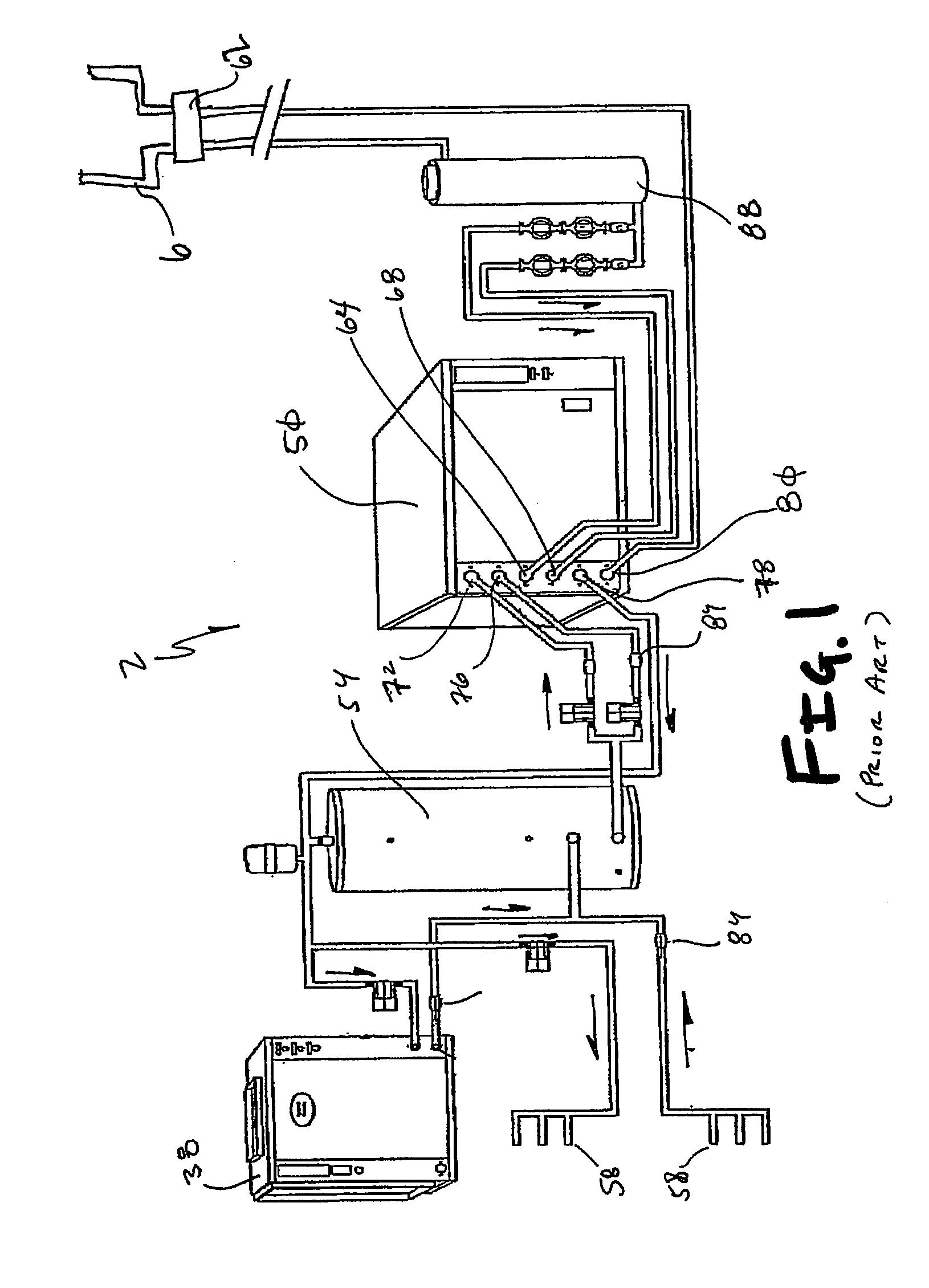

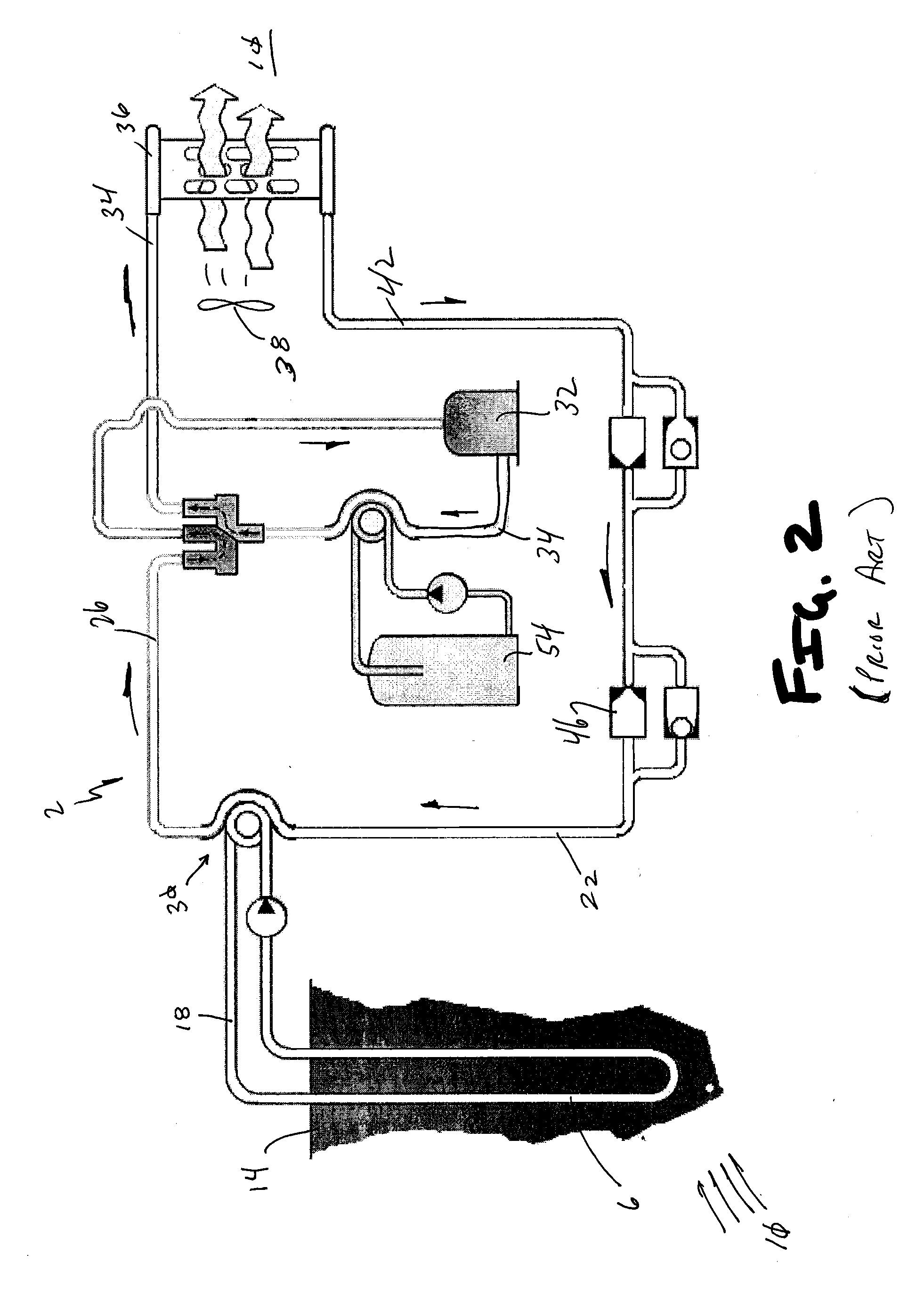

[0021]Referring now to FIGS. 1 and 2, a ground source heat exchange system 2 of the prior art is shown. More specifically, as is well understood by one skilled in the art, the prior art heating system 2 employs a ground loop 6 that is positioned either horizontally or vertically within the earth surface. The latent heat 10 of the ground 14 is transferred to the cooler fluid 18 in the ground loop 6 via heat conduction. The now heated warm fluid 18 in the loop is then placed in thermal communication with a coolant loop 22 via a heat exchanger 30 wherein the heat from the ground loop 6 is transferred to coolant contained in the coolant loop 22. The cold coolant vapor 26 produced by the heat exchanger 30 is then compressed by a compressor 32, thereby converting electro-mechanical energy into heat energy that increases the temperature of the vapor. The now hot vapor 34 is then directed to a condenser 36 wherein the heat energy may be extracted therefrom via a fan 38, for example, to heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com