Water cooling device for model toy engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

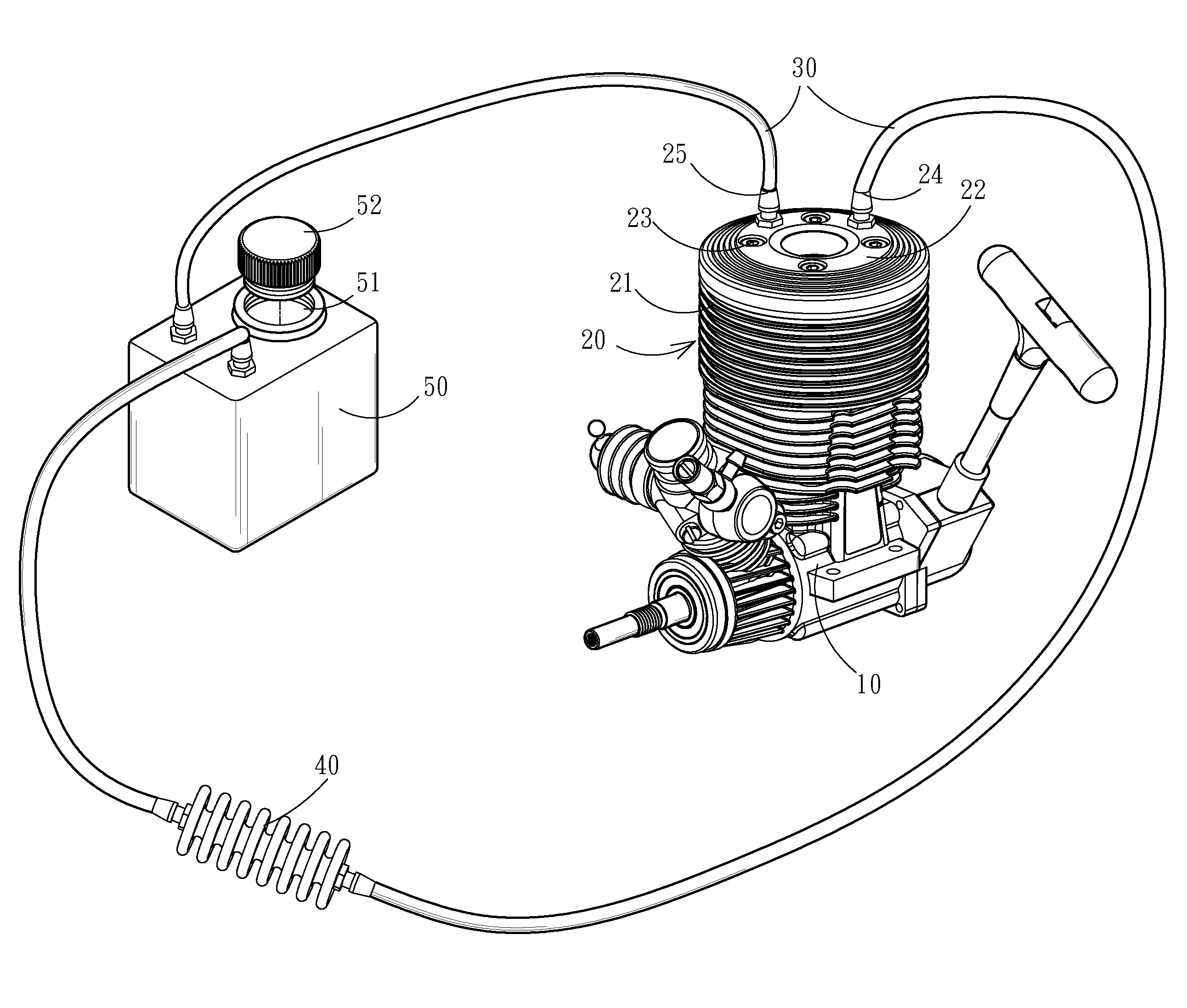

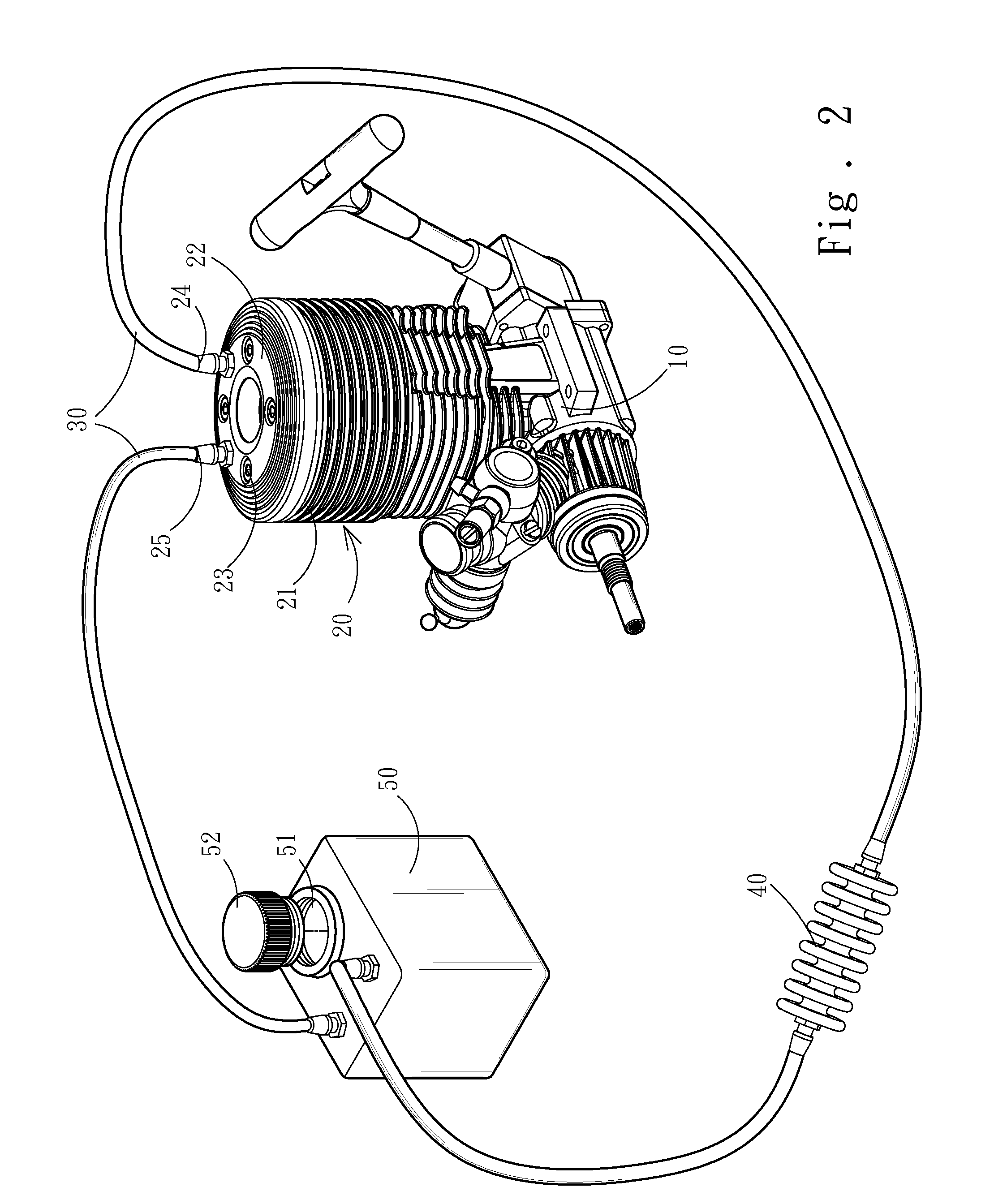

[0014]Refer to FIG. 2, FIG. 3A, and FIG. 3B. The water cooling device for a model toy engine of the present invention comprises an engine 10, a radiator 20, a pipe 30, a cooler 40, and a water tank 50.

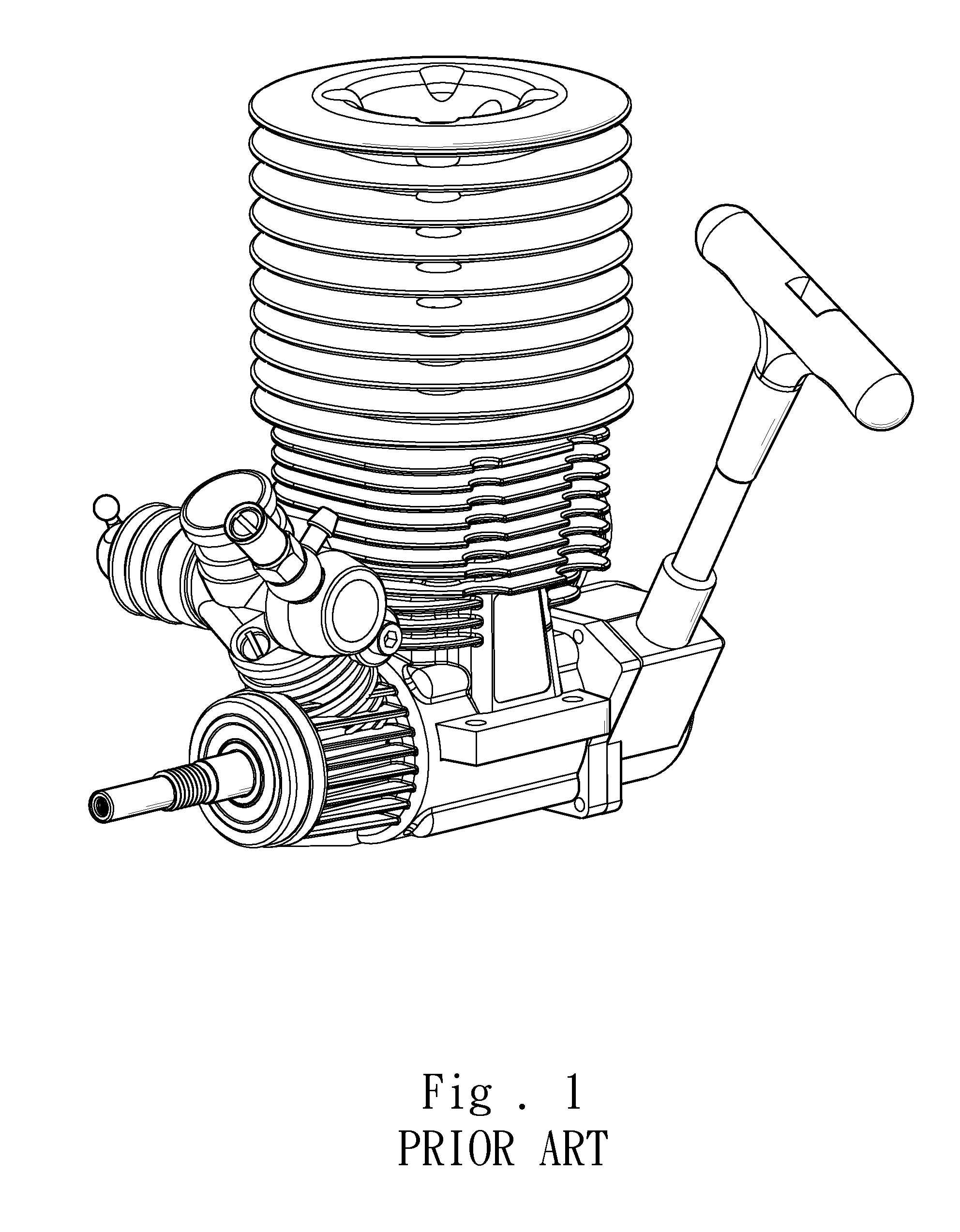

[0015]The engine 10 is installed on a model toy, such as a model toy car or a model airplane.

[0016]The radiator 20 is arranged on the engine 10. The radiator 20 is a hollow body and has a plurality of fins 21 on the surface thereof. The top of the radiator 20 has a cover 22, and the cover 22 has four screws 23. The screws 23 pass through the body of the radiator 20 and fasten the radiator 20 to the engine 10. The top of the radiator 20 also has a water outlet 24 and a water inlet 25. A tube 26 extends from below the water outlet 24 to an appropriate depth inside the radiator 20. Water is filled into the radiator 20 to about 80% capacity.

[0017]One end of the pipe 30 is connected with the water outlet 24 of the radiator 20, and the other end is connected with the water inlet 25 of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com