Medicine, Food and Drink or Feed Containing Sphingomyelin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

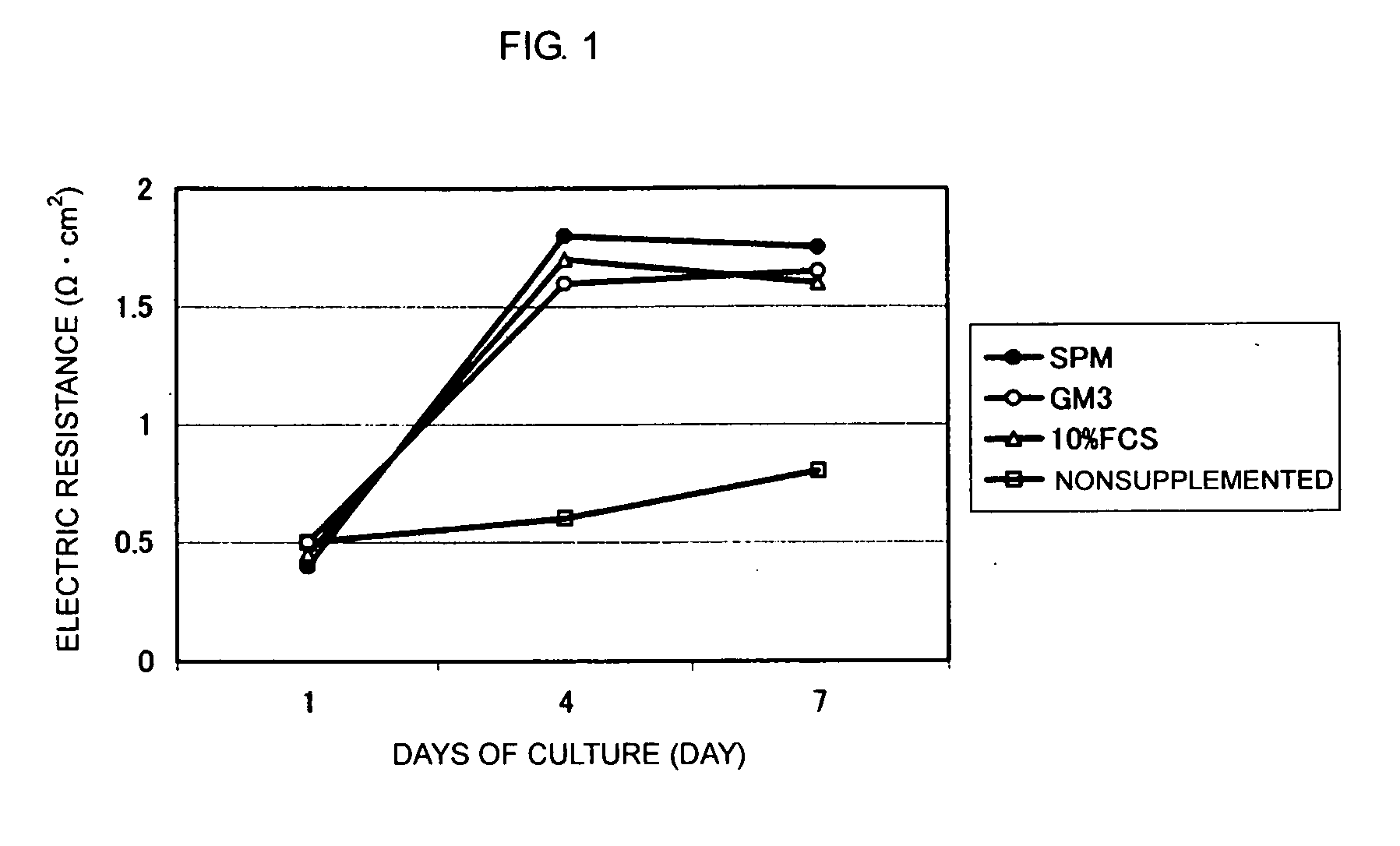

Image

Examples

example 1

[0021]A reaction solution obtained by allowing protease to act on a 10% aqueous solution of a whey protein concentrate (WPC) was subjected to extraction with a chloroform-methanol (2:1) solution, and the extract was then concentrated and further subjected to acetone extraction to obtain a complex lipid fraction. Next, this complex lipid fraction was subjected to stepwise extraction with a chloroform-methanol solution using Florisil column chromatography to obtain a phospholipid fraction. This phospholipid fraction was subjected to stepwise extraction with a chloroform-methanol solution using silica gel chromatography to obtain a fraction, which was then freeze-dried to obtain a sphingomyelin raw material. This sphingomyelin raw material was treated by thin-layer chromatography, followed by color development with a Dittmer reagent. A sphingomyelin content measured by a densitometry method was 95.2%. This sphingomyelin raw material can be used directly as an agent of the present inven...

example 2

[0082]Raw materials were mixed according to formulation shown in Table 18 and then compressed into 1 g by a standard method to produce the pharmaceutical agent of the present invention in a tablet form.

TABLE 18Hydrous crystalline glucose83.5(% by weight)Sphingomyelin raw material10.0(sphingomyelin content: 10%,Phospholipid 500,manufactured by Fonterra)Mineral mixture5.0Sugar ester1.0Flavor0.5In this context, this pharmaceutical agent (1 g) contained 10 mg of sphingomyelin.

example 3

[0083]50 g of a sphingomyelin raw material having a sphingomyelin content of 25% (Phospholipid 700, manufactured by Fonterra) was dissolved as the agent of the present invention in 4950 g of deionized water, and the solution was heated to 50° C. and then mixed by stirring at 6000 rpm for 30 minutes using a TK homomixer (TK ROBO MICS; manufactured by Tokushu Kika Kogyo Co., Ltd.) to obtain a sphingomyelin solution having a sphingomyelin content of 250 mg / 100 g. Into 4.0 kg of this sphingomyelin solution, 5.0 kg of casein, 5.0 kg of soybean proteins, 1.0 kg of fish oil, 3.0 kg of perilla oil, 18.0 kg of dextrin, 6.0 kg of a mineral mixture, 1.95 kg of a vitamin mixture, 2.0 kg of an emulsifier, 4.0 kg of a stabilizer, and 0.05 kg of a flavor were formulated, and this formulation was packaged into a 200-ml retort pouch and sterilized at 121° C. for 20 minutes using a retort sterilizer (primary pressure vessel, TYPE: RCS-4CRTGN, manufactured by Hisaka Works, Ltd.) to produce 50 kg of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com