Fabrication materials and techniques for plate heat and mass exchangers for indirect evaporative coolers

a technology of mass exchangers and fabrication materials, which is applied in the direction of domestic cooling apparatus, heating types, applications, etc., can solve the problem of limiting the height of plates that can be used, and achieve the effect of improving fabrication materials and techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

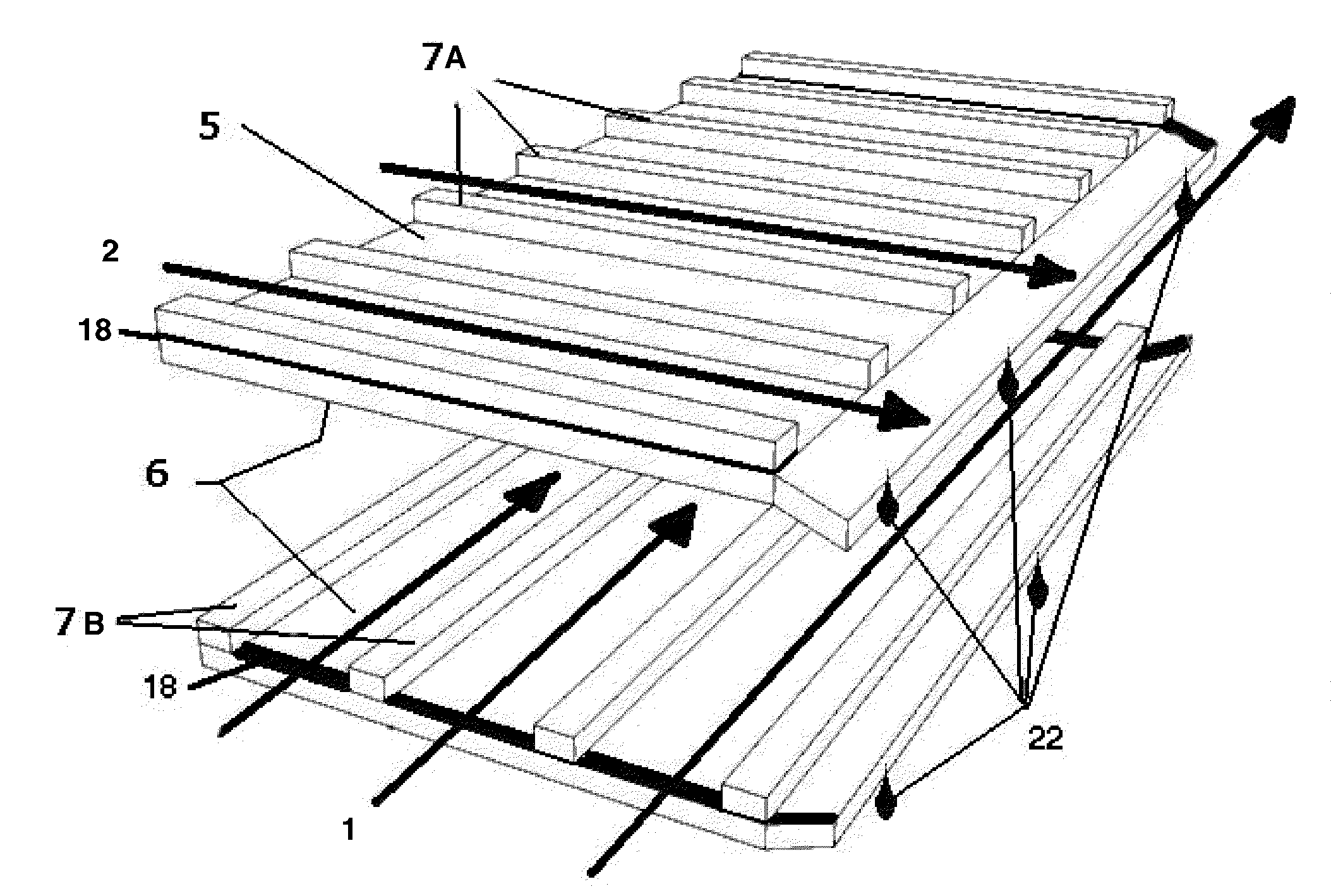

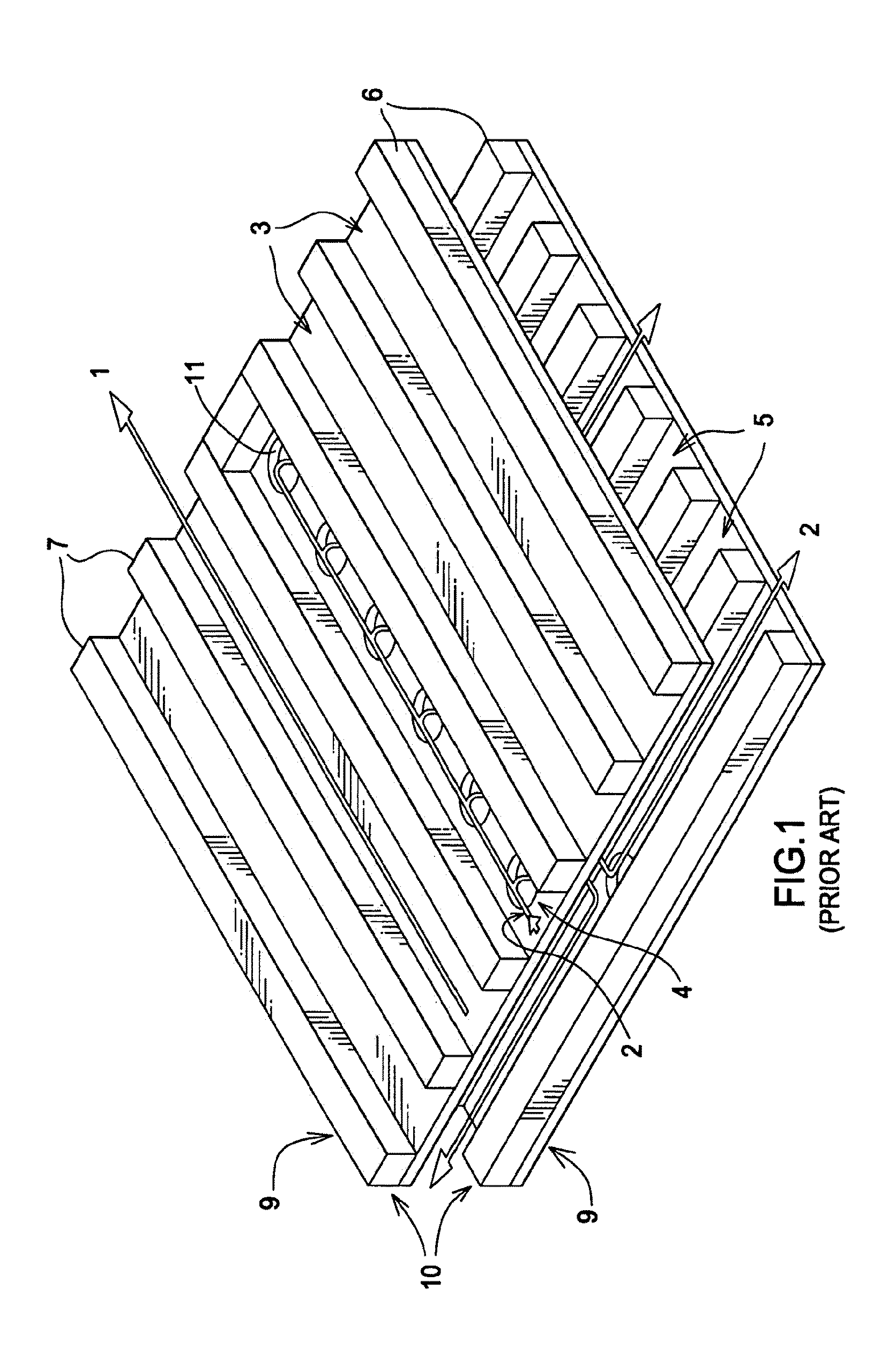

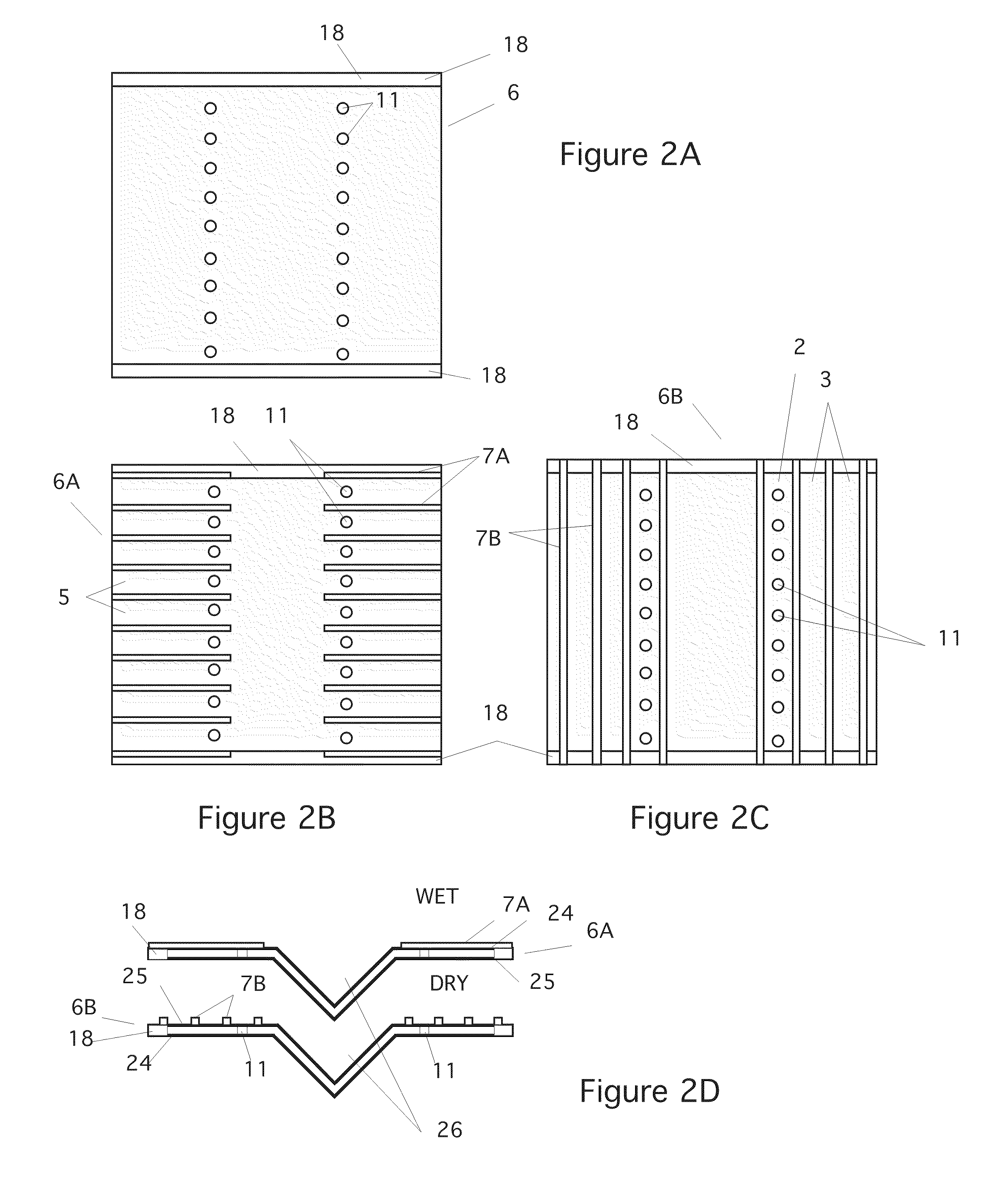

[0024]FIGS. 2 and 4A-D show embodiments of improved fabrication materials and techniques for heat transfer plates in indirect evaporative coolers. FIG. 3 shows an example of a fabrication process according to the present invention. While several embodiments are shown and discussed, it will be apparent to those skilled in the art that many other indirect evaporative cooler plate configurations are possible. U.S. Pat. Nos. 6,581,402, 6,705,096, and 7,228,699, incorporated herein by reference, show a variety of plate configurations, and others are known as well.

[0025]The following table lists reference numbers used in this patent:

1dry side product fluid (e.g. air) 2working gas (e.g. air) 3dry side product channels 4dry side working channels 5wet side channels 6Awet plates 6Bdry plates 7Awet channel guides 7Bdry channel guides 9dry sides of plates10wet sides of plates11perforations18seals22evaporative fluid (e.g. water)23trough for wetting plates24non-permeable side25wicking side26trou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| permeability | aaaaa | aaaaa |

| hydrophobic | aaaaa | aaaaa |

| non-permeable | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com