Process for producing methionine

- Summary

- Abstract

- Description

- Claims

- Application Information

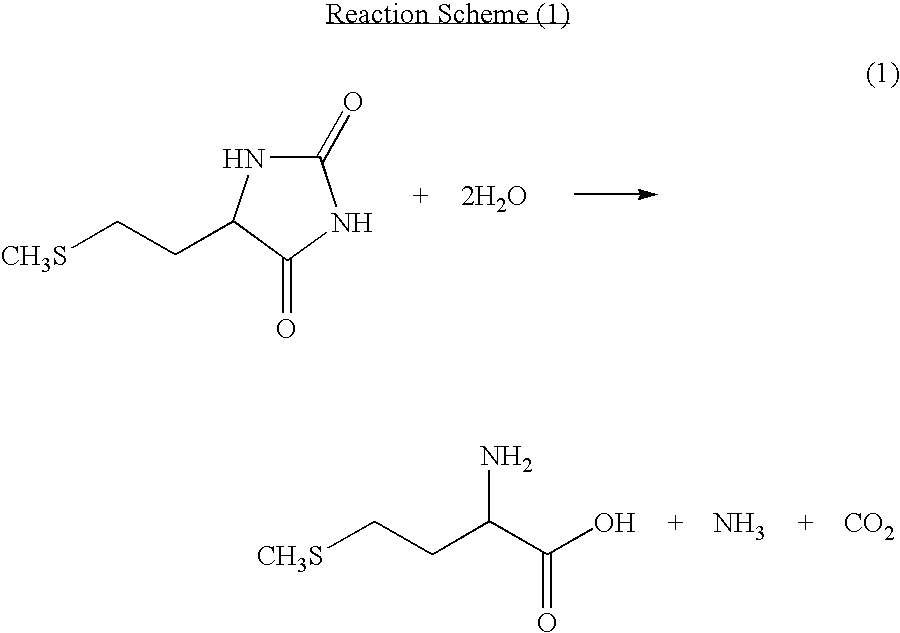

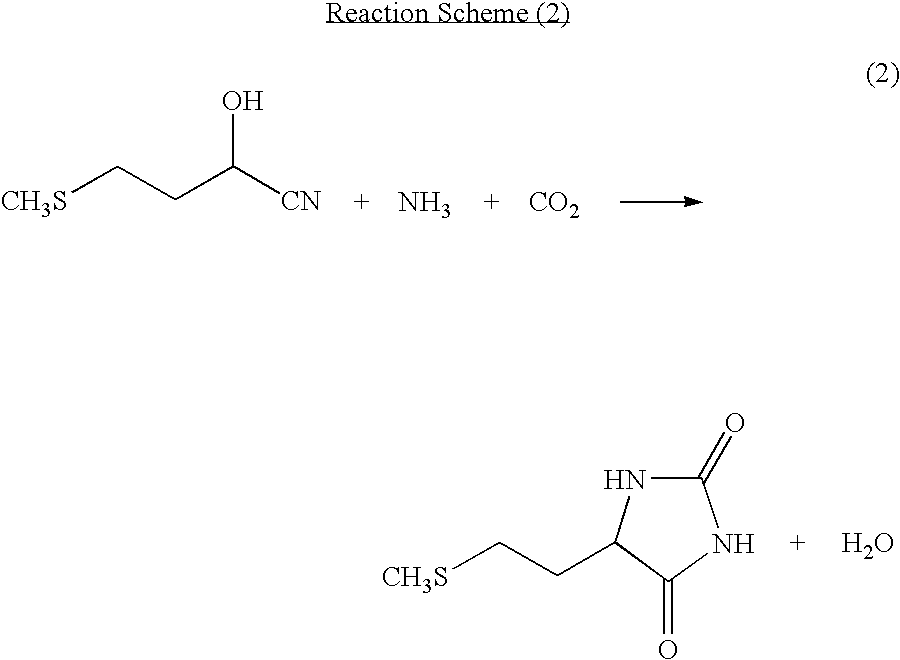

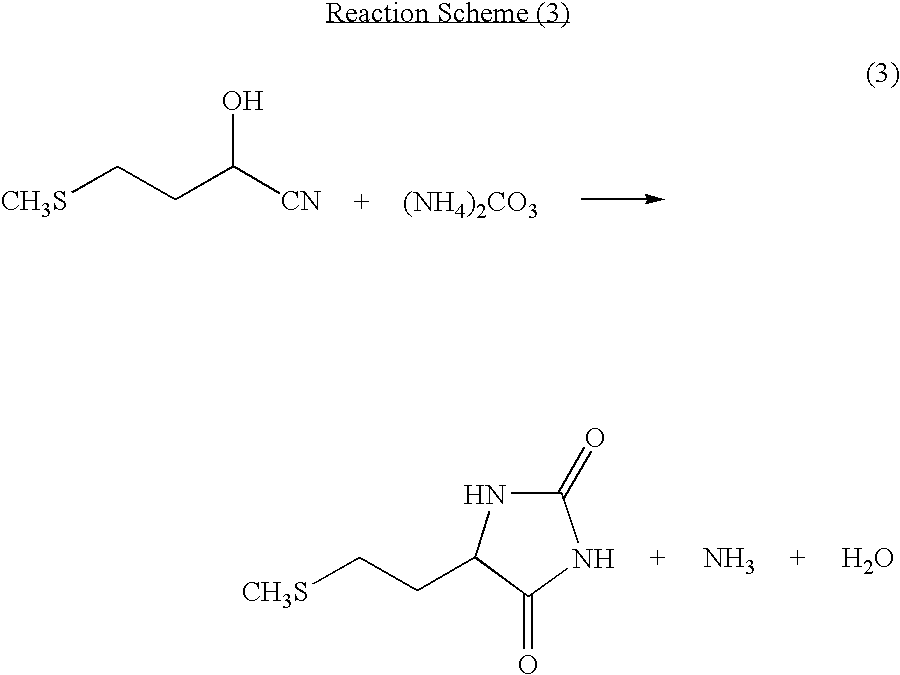

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0055]Into a non-stirred continuous first reaction tank, 5.4 parts per hour of a mixture of a solution containing 5-[2-(methylthio)ethyl]imidazolidine-2,4-dione and a potassium hydroxide aqueous solution was continuously charged. While carbon dioxide and ammonia produced as by-products were continuously distilled off together with water, the reaction solution was continuously charged into a second non-stirred continuous reaction tank which was different from the first reaction tank. At this point, the temperature of the reaction tanks was 177° C. and the gauge pressure was 0.88 MPa. The residence time in the first reactor was 30 minutes, and the residence time in the second reaction tank was 6 minutes, totaling 36 minutes. After reaction, the hydrolyzed solution thus obtained contained 10.4% of potassium, 13.1% of methionine, and 1.29% of methionine dipeptide, and the proportion of methionine dipeptide to methionine was 9.9%.

[0056]Into a reactor, 1 part of the hydrolyzed solution wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com