Biorenewable naphtha

a biorenewable naphtha and biomass technology, applied in the direction of hydrocarbon preparation catalysts, hydrocarbon oil treatment products, fuels, etc., can solve the problems of reducing the efficiency of this process as a source of biorenewable naphtha, gasifiers with low reliability record, and f-t conversion capital costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Hydrotreating of a Biorenewable Feed Stock

[0043]The present example demonstrates how naphtha was made from a renewable feedstock. A 100 cc isothermal tubular reactor was filled with 80 cc of a commercial NiMo catalyst and +70-100 mesh glass beads. The catalyst was sulfided with dimethyl disulfide. The sulfiding procedure included step-wise temperature increase to 650° F. After sulfiding, the reactor was cooled to 400° F.

[0044]Next a triglyceride / fatty acid feed was introduced to the isothermal reactor. The reactor was slowly heated to 650° F. to achieve full conversion of the triglyceride / fatty acid feed to n-paraffins. The reactor temperature was further increased to 700° F. to maintain good catalyst activity at 80 cc / hr feed rate (1 LHSV).

[0045]The hydrotreater performance with beef tallow as the triglyceride / fatty acid feed is summarized in Table 1. The yield of total products on feed basis exceeds 100% in part due to addition of hydrogen and also due to measurement errors associ...

example 2

Hydrocracking of Bio-Derived Heavy Hydrocarbons

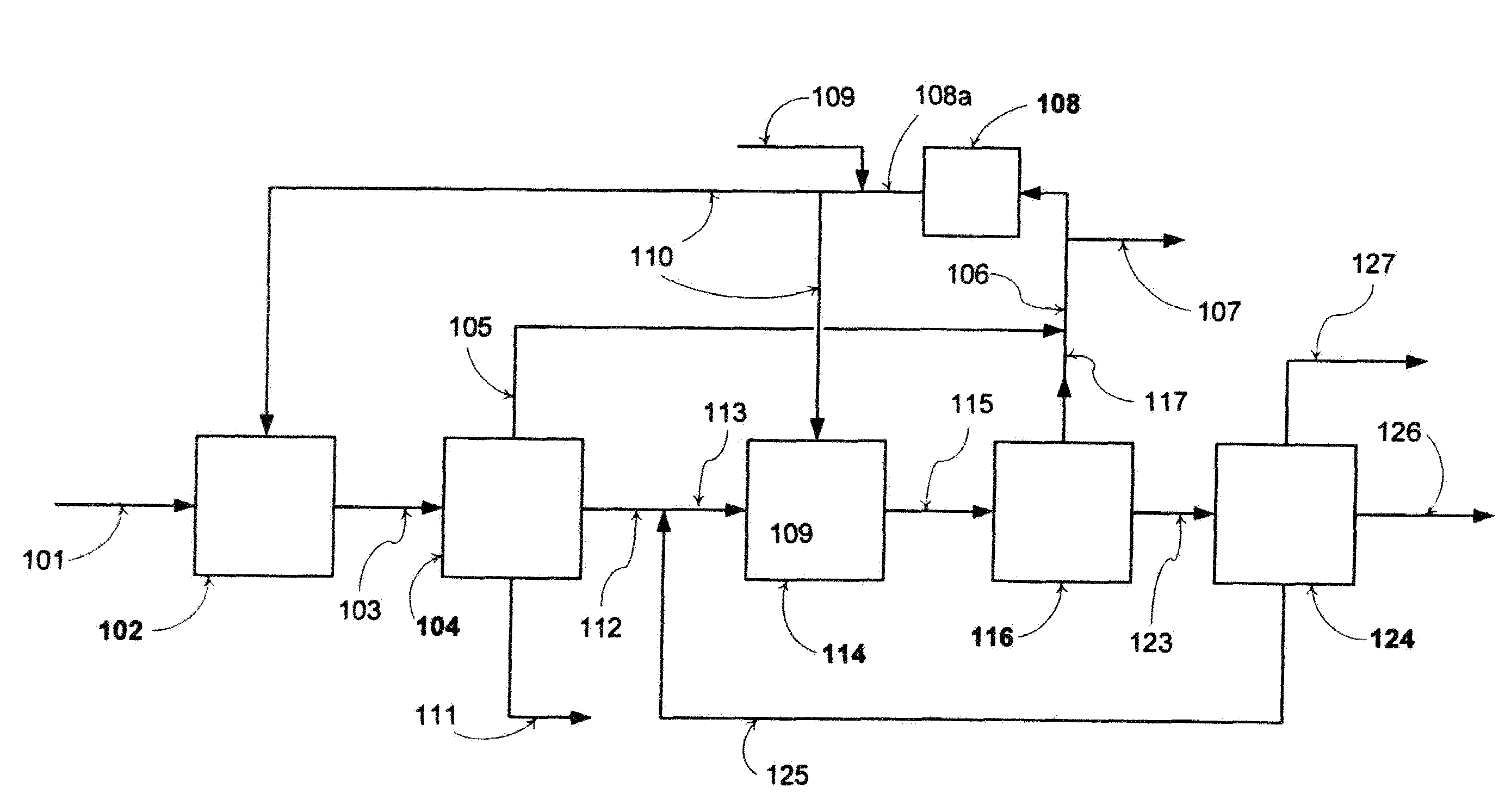

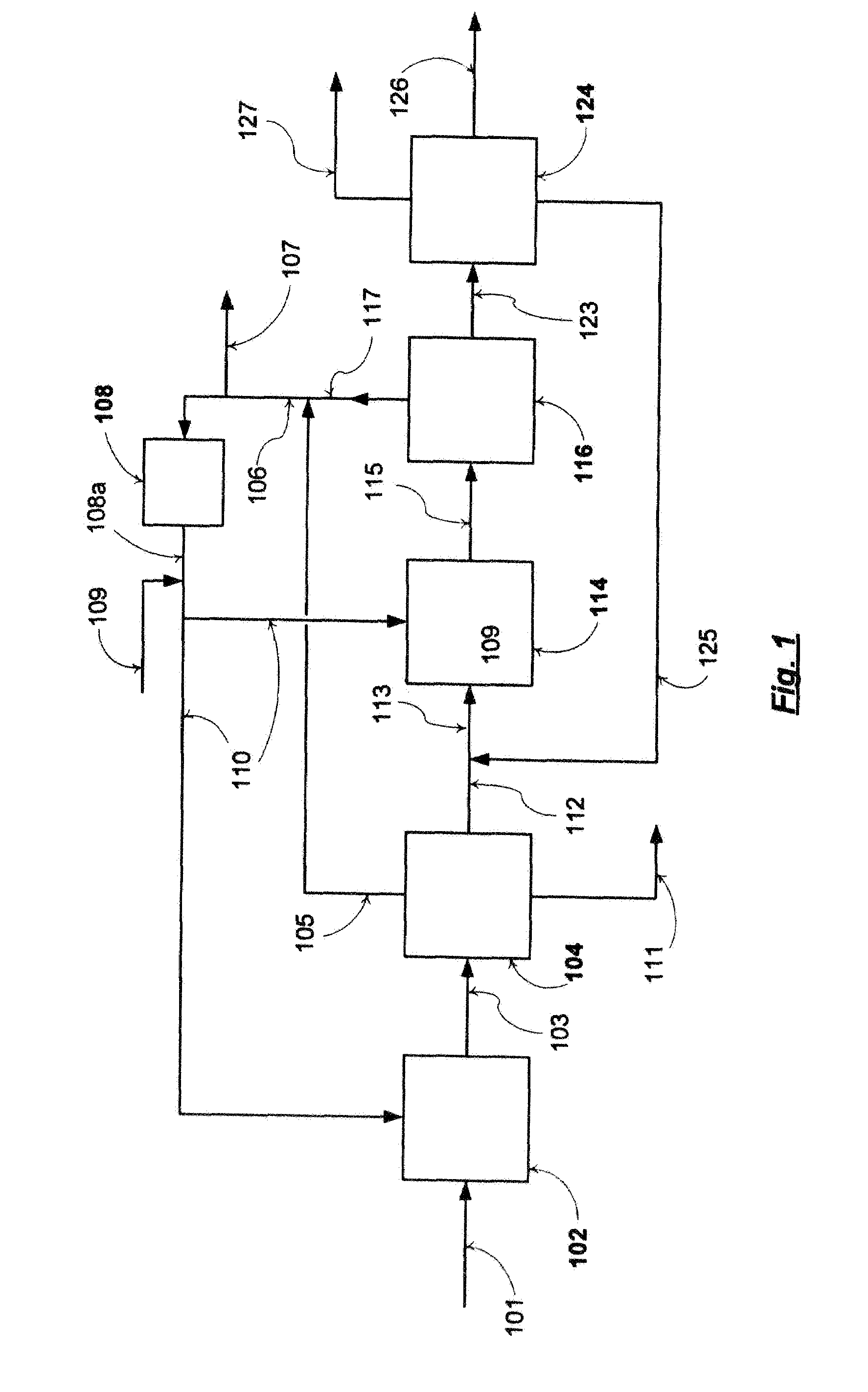

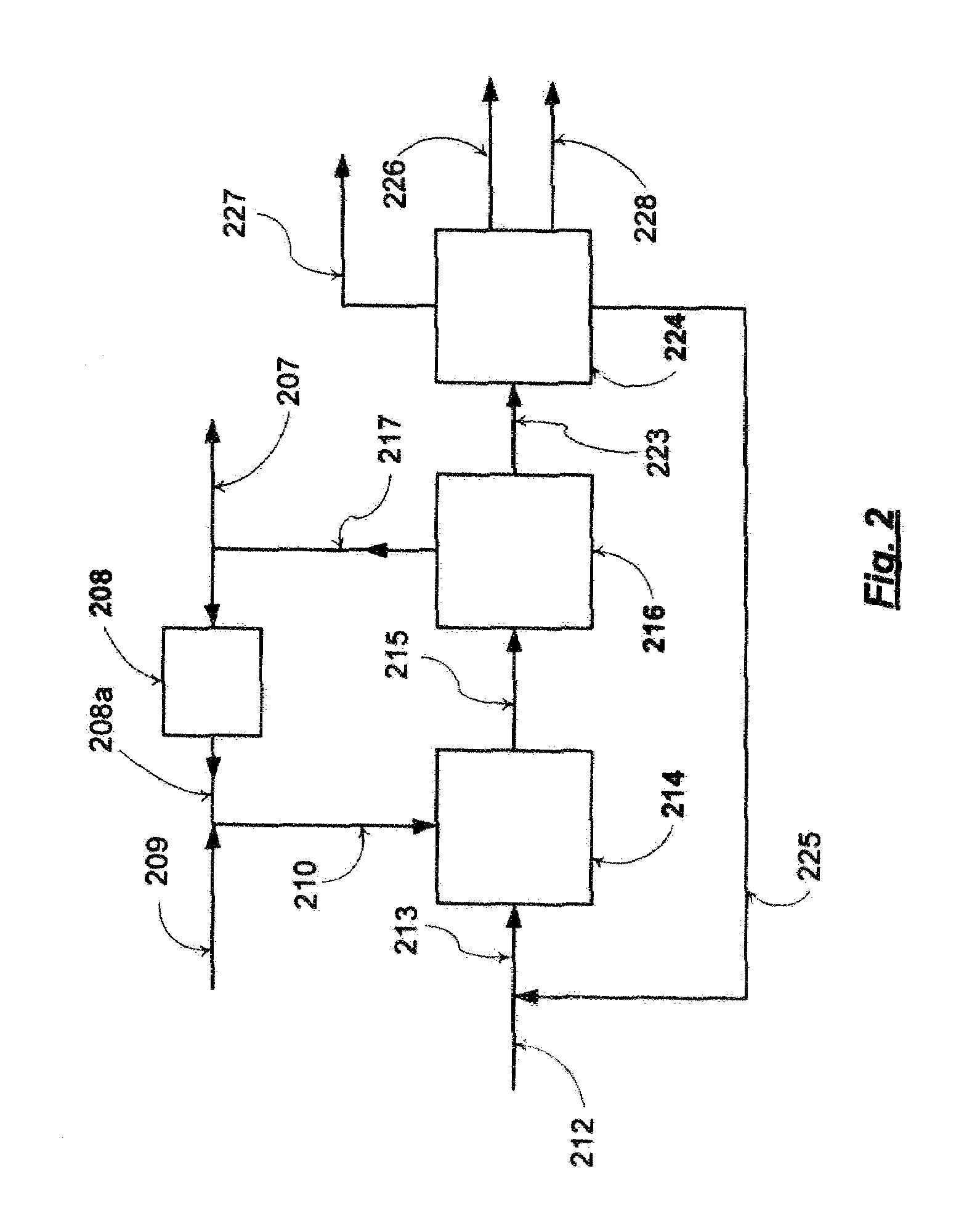

[0047]The mainly C15-C18 n-paraffin composition obtained from hydrotreating bio-renewable feed stocks was used as feed for a hydrocracking pilot plant. These long chain hydrocarbons were derived via hydrotreating a biorenewable feed in a procedure similar to Example 1. The bio-renewable feed was a blend of chicken fat (45%), brown grease (19%), yellow grease (18%), floatation grease (9%), and miscellaneous waste animal fats from industrial food processing operations (9%). The hydrocracking pilot plant was a prototype of the embodiment of the present invention represented by FIG. 2.

[0048]The hydrocracker reactor system was loaded with 4.8 liters of a commercial hydrocracking catalyst. The catalyst was platinum-palladium on amorphous alumina / silica

[0049]The reactor was pressurized to 1,000 psig. After catalyst preconditioning, the temperature was increased again to achieve the desired level of hydrocracking to produce the biorenewable nap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com