Laser processing method

a laser processing method and laser technology, applied in the field of laser processing methods, can solve the problems of defective appearance, increased likelihood of air bubble growth and bursting, and increased likelihood of bursting, so as to achieve efficient heat in the vicinity of the first surface, and reduce the chance of bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

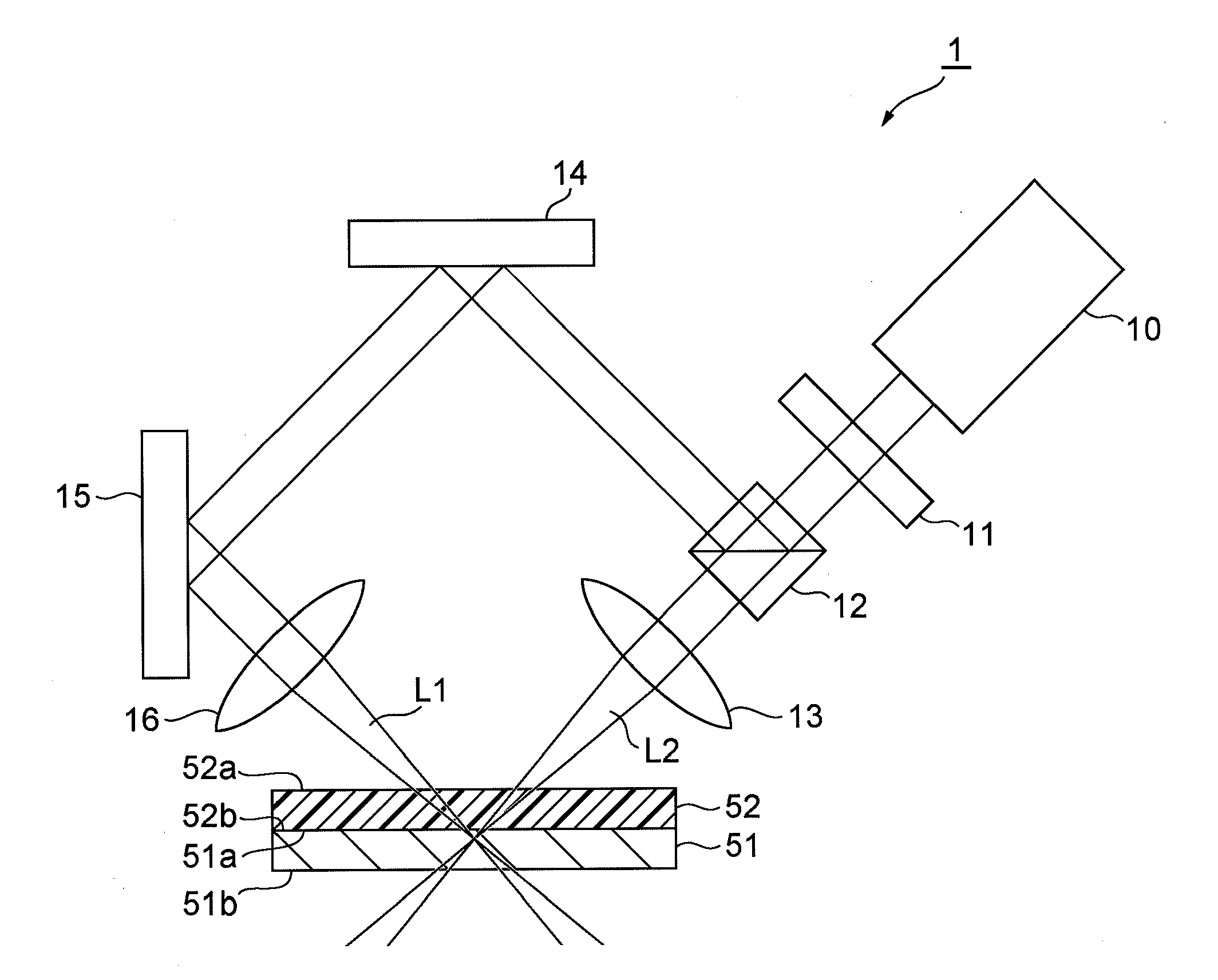

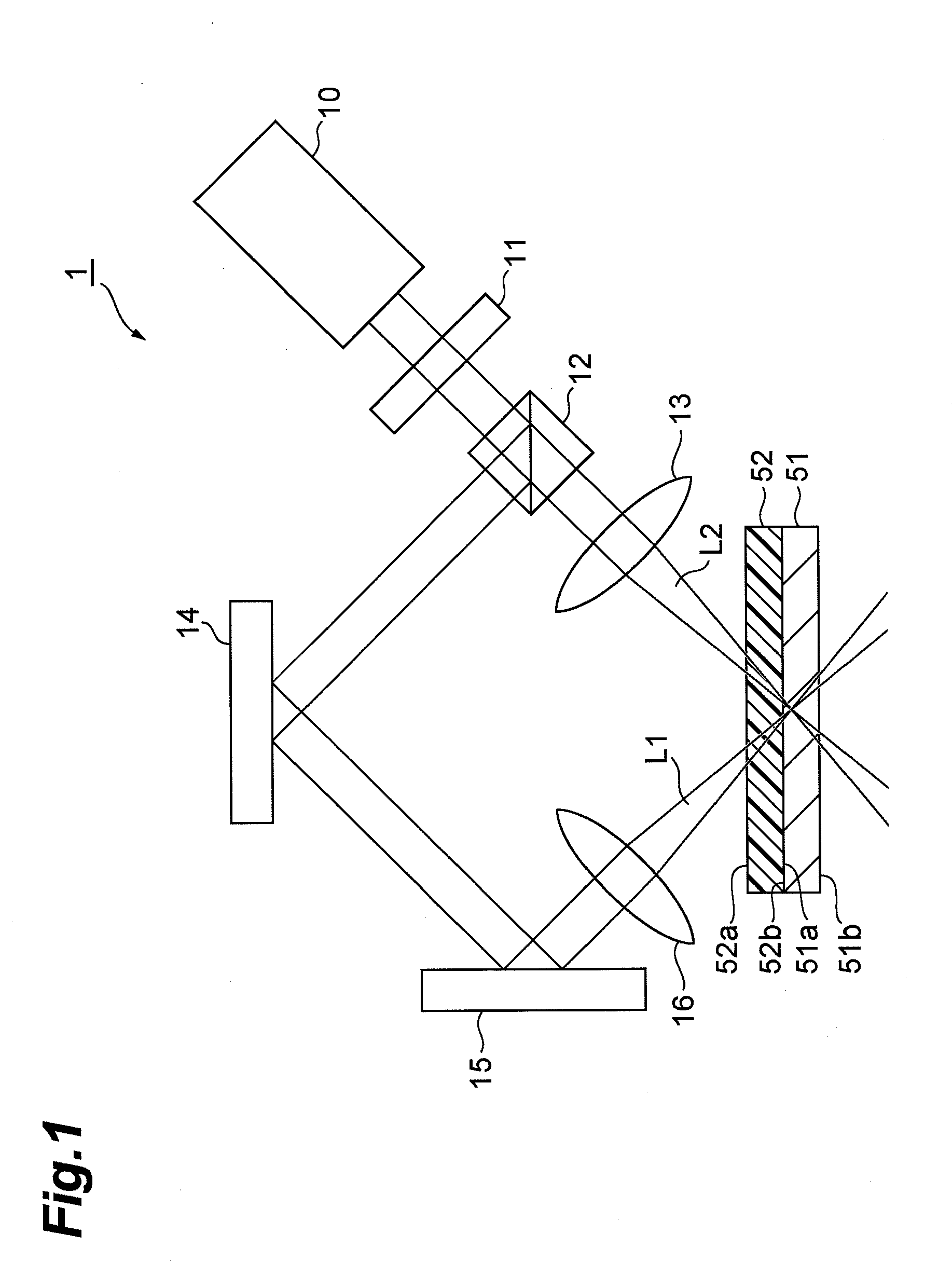

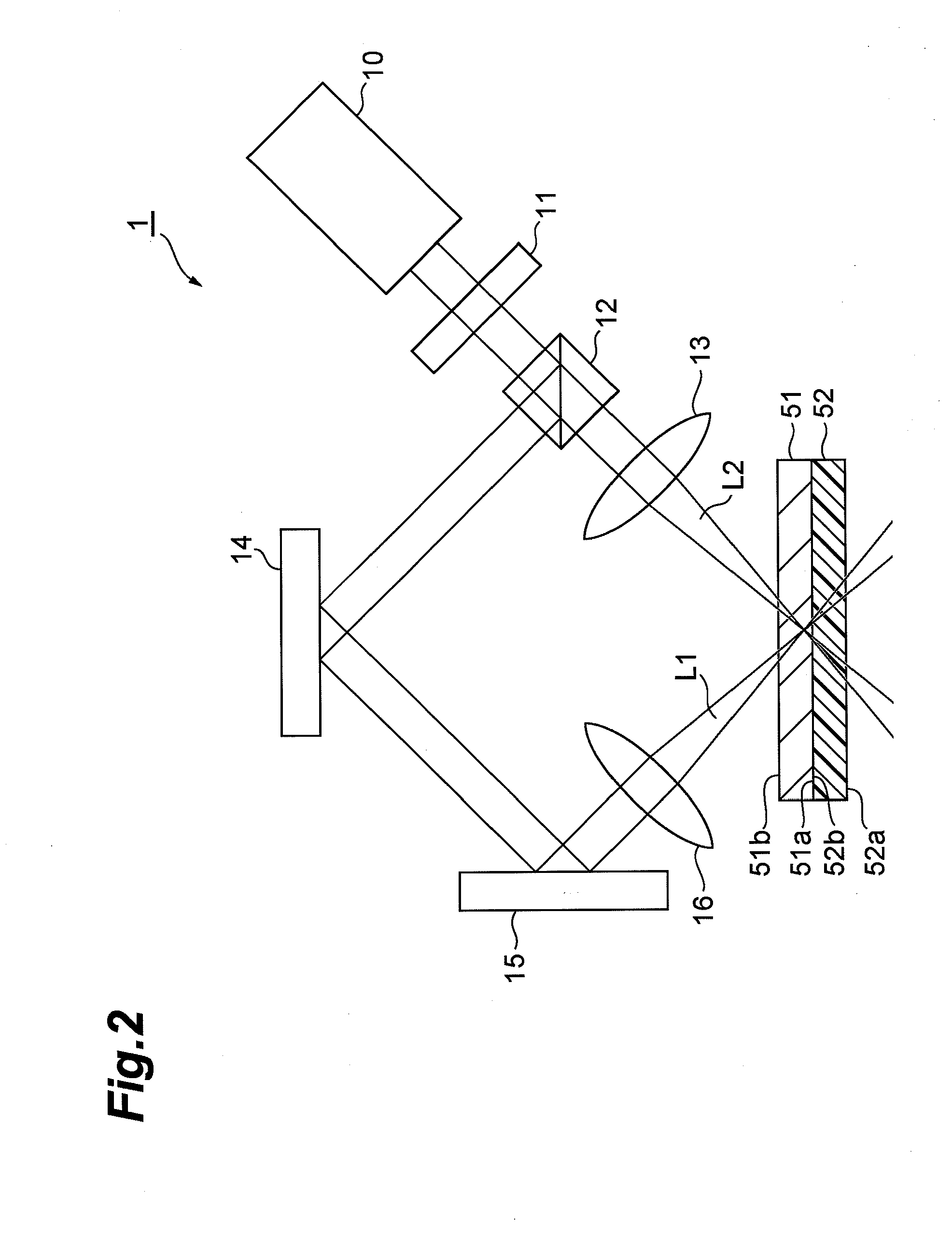

[0030]FIG. 1 is a view for explaining a first embodiment of the laser processing method according to the present invention. The laser processing apparatus 1 shown in FIG. 1 comprises a laser light source 10, diffractive optical element (DOE) 11, beam splitter 12, first lens 13, first mirror 14, second mirror 15, and second lens 16. The laser processing apparatus 1 shown in this FIG. 1 splits a laser beam from the laser light source 10 into two, and irradiates these two laser beams onto an object to be processed comprising a metal member 51 and a plastic member 52 so as to focus the laser beams in the vicinity of the surface of the metal member 51. Furthermore, the metal member 51 has a first surface 51a, and a second surface 51b that is opposite this first surface 51a, and similarly, the plastic member 52 also has a first surface 52a, and a second surface 52b that is opposite this first surface. Therefore, when the object to be processed is constituted by placing the plastic member ...

second embodiment

[0046]FIG. 4 is a view for explaining a second embodiment of the laser processing method according to the present invention. The laser processing apparatus 2 shown in FIG. 4 comprises a laser light source 10, DOE 11, first axicon lens 17, second axicon lens 18 and a lens 19. The laser processing apparatus 2 shown in FIG. 4 individually focuses a plurality of laser beams, and irradiates an object to be processed, which comprises a metal member 51 and a plastic member 52. Furthermore, in this second embodiment, the metal member 51 has a first surface 51a, and a second surface 51b that is opposite this first surface 51a, and the plastic member 52 also has a first surface 52a, and a second surface 52b that is opposite this first surface 52a. Therefore, when the object to be processed is constituted by placing the plastic member 52 on the metal member 51, the first surface 51a of the metal member 51 and the second surface 52b of the plastic member 52 make contact. Further, the interface ...

third embodiment

[0055]FIG. 6 is a view for explaining a third embodiment of the laser processing method according to the present invention. The laser processing apparatus 3 shown in FIG. 6 comprises a first laser light source 20, first DOE 21, first lens 22, second laser light source 30, second DOE 31 and second lens 32. Further, the laser processing apparatus 3 shown in FIG. 6 irradiates an object to be processed constituted from a metal member 51 and a plastic member 52 by individually focusing a plurality of laser beams. In this third embodiment as well, the metal member 51 has a first surface 51a, and a second surface 51b that is opposite this first surface 51a, and the plastic member 52 also has a first surface 52a, and a second surface 52b that is opposite this first surface 52a. Therefore, when the object to be processed is constituted by placing the plastic member 52 on the metal member 51, the first surface 51a of the metal member 51 and the second surface 52b of the plastic member 52 make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com