Method for tandem gas metal arc welding, and welding torch and welding apparatus used therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

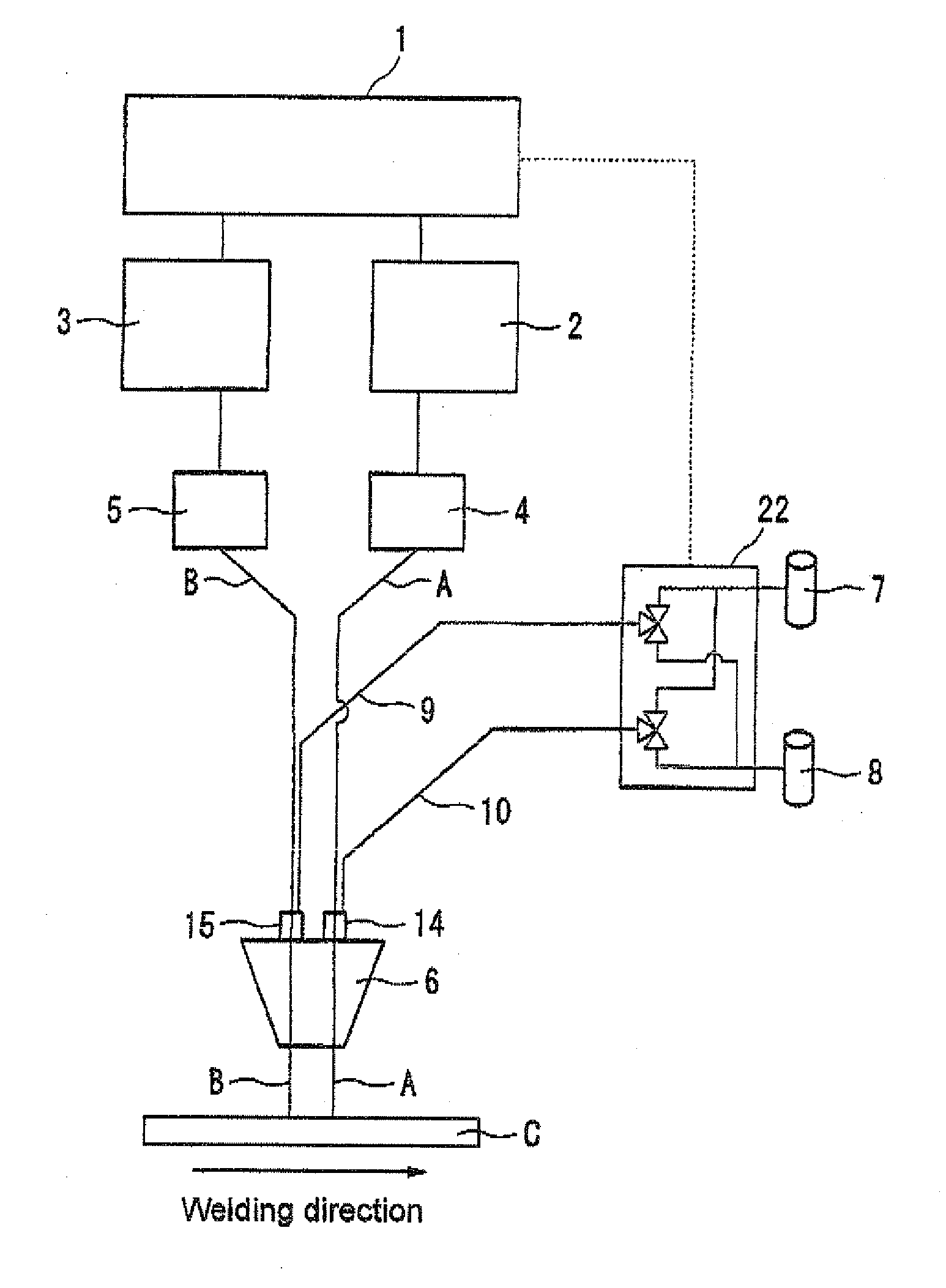

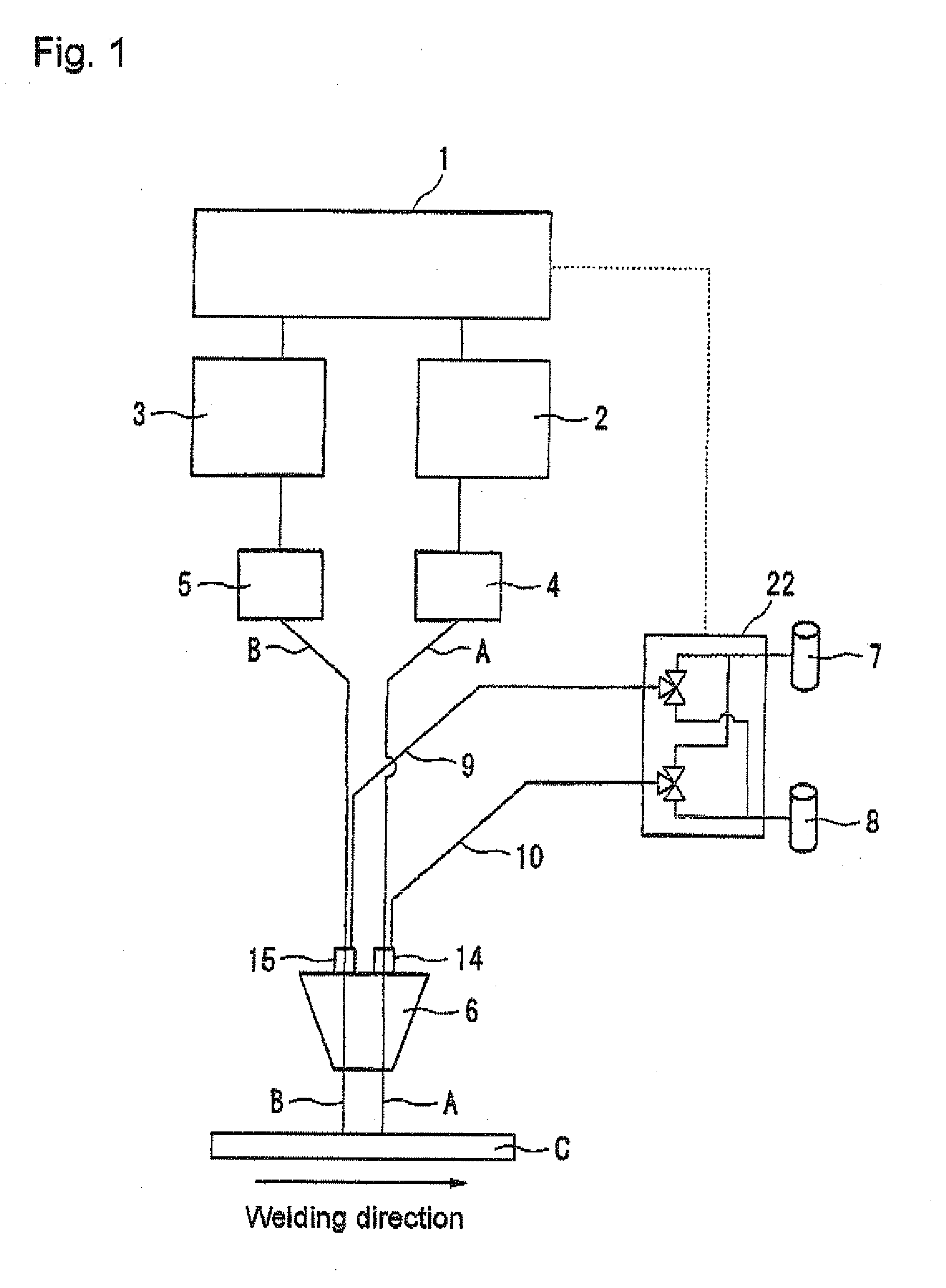

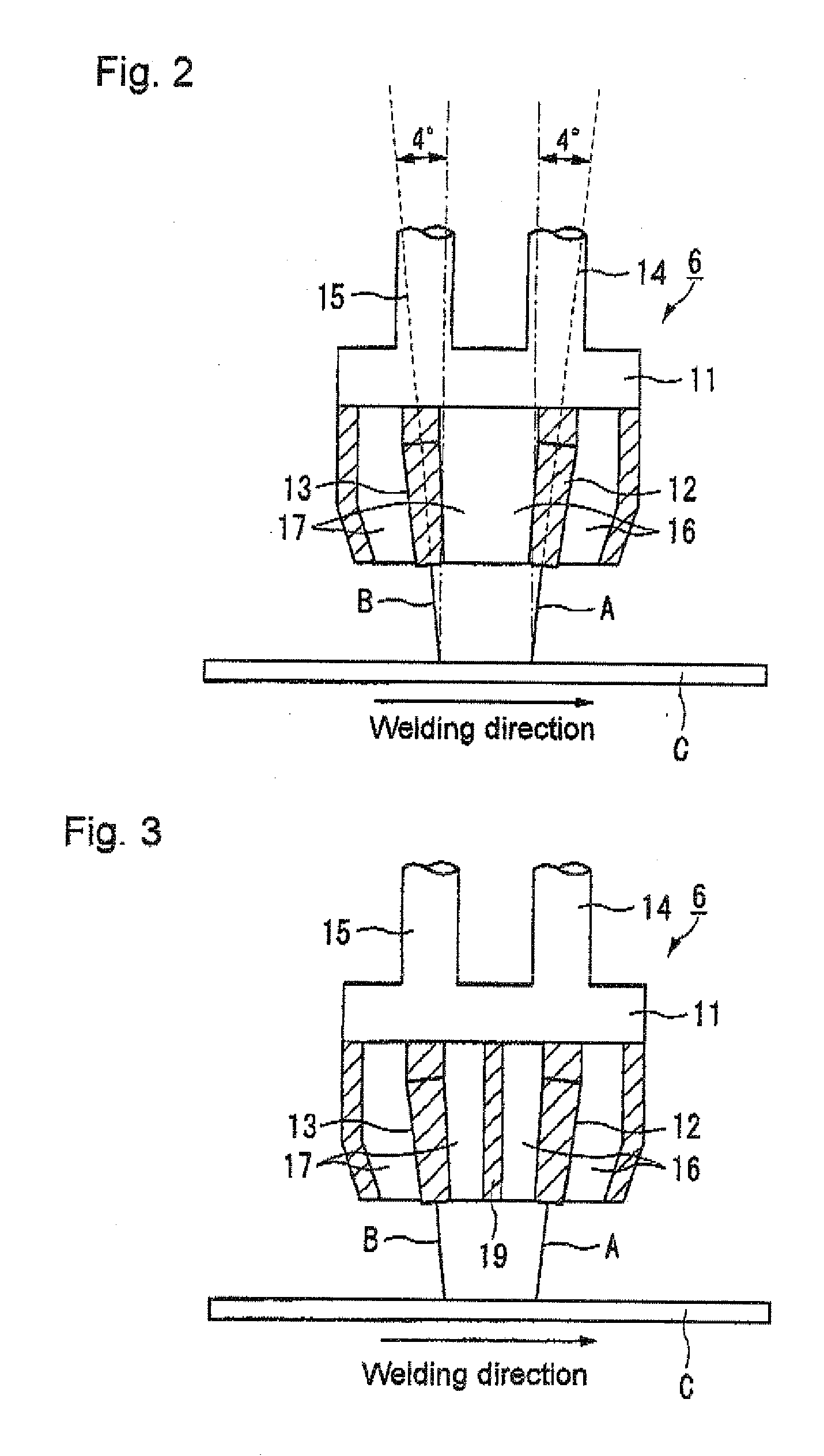

[0089]In order to confirm the effects obtained by the present invention, bead-on-plate welding was carried out using the tandem GMA welding apparatus and the welding torch shown in FIGS. 1 and 2, and then the amount of the spatter generated and penetration conditions were evaluated.

[0090]As the shielding gas for the leading and trailing electrodes, a two-component mixed gas containing argon and carbon dioxide was used. Moreover, the composition of the shielding gas was changed. All of the spatter generated in welding was corrected using a spatter collection box, and the amount of the spatter was measured. The flow rate of the shielding gas for the leading electrode and the trailing electrode was adjusted to 25 L / min individually.

[0091]A solid wire (YGW11) having a diameter of 1.2 mm was used as the welding wire. The welding current for mild steel in both electrodes was fixed at 325A. The arc voltage was adjusted to a boundary voltage, at which the short circuiting transfer changes t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by volume | aaaaa | aaaaa |

| Percent by volume | aaaaa | aaaaa |

| Percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com