Bulk Metallic Glass/Graphite Composites

a graphite and metallic glass technology, applied in the field of composite materials, can solve the problems of inability to fully exploit the properties of properties, general brittleness of metallic glasses, and inability to deformation through dislocation movement, and achieve the effects of high yield strength, high plasticity, and high plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

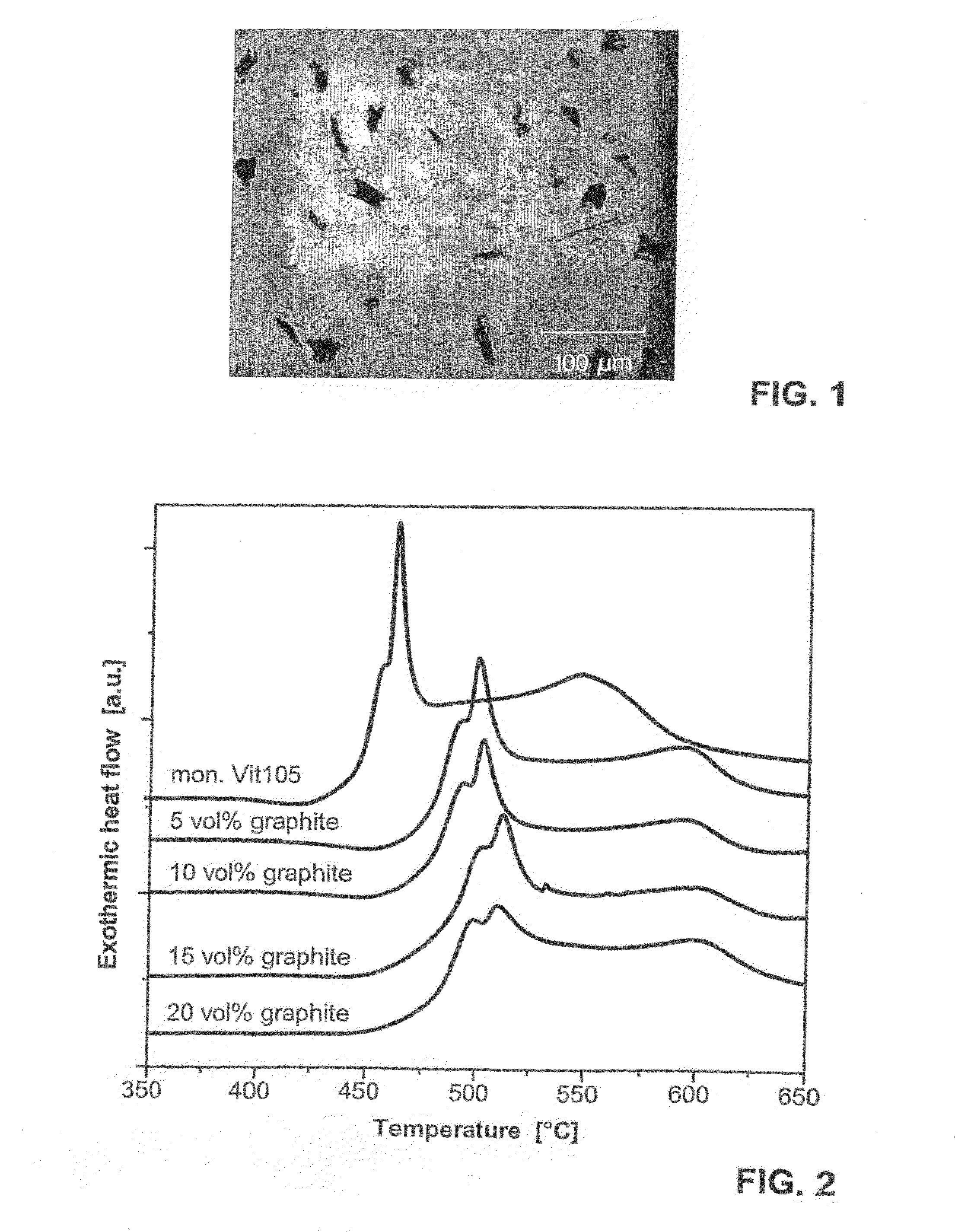

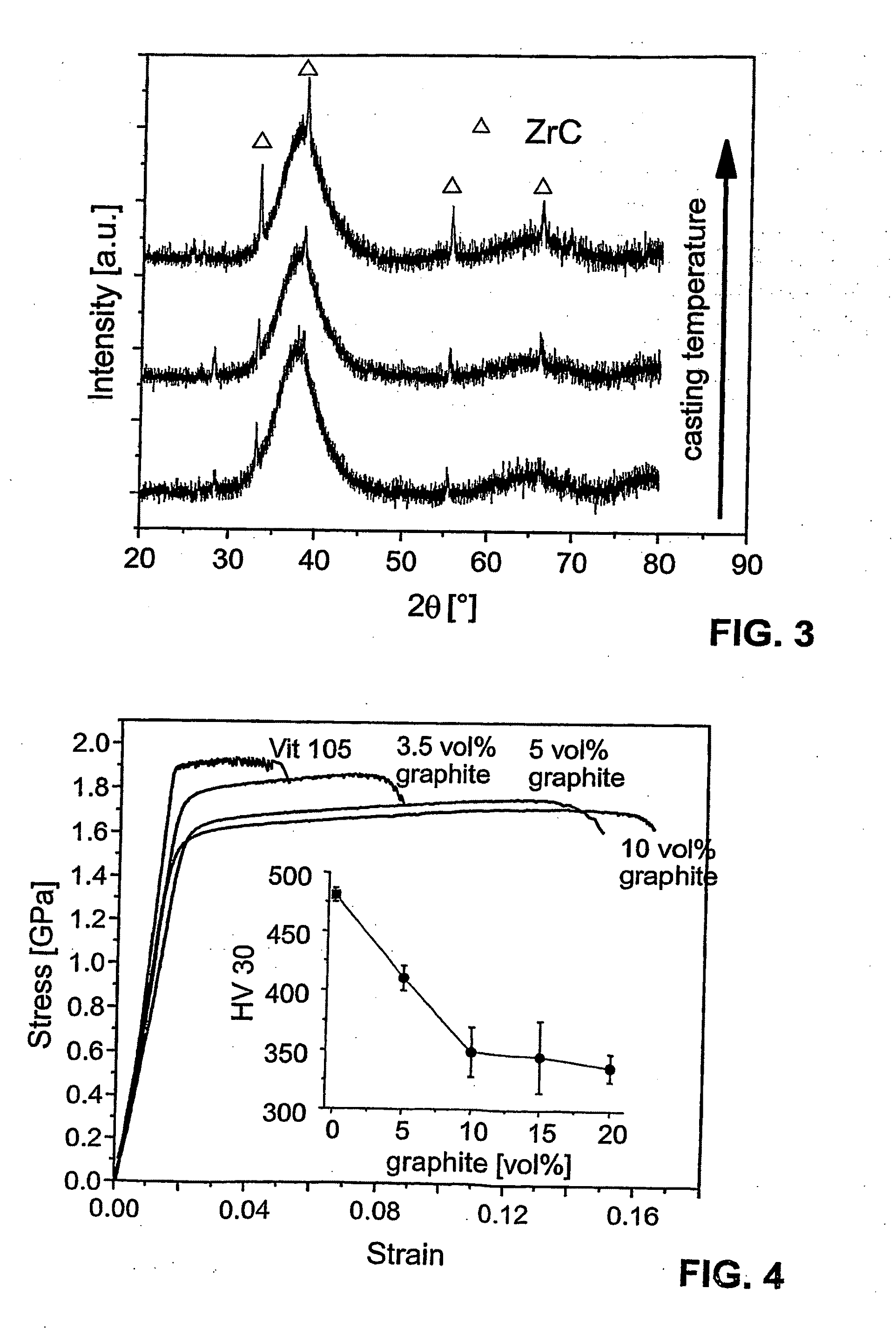

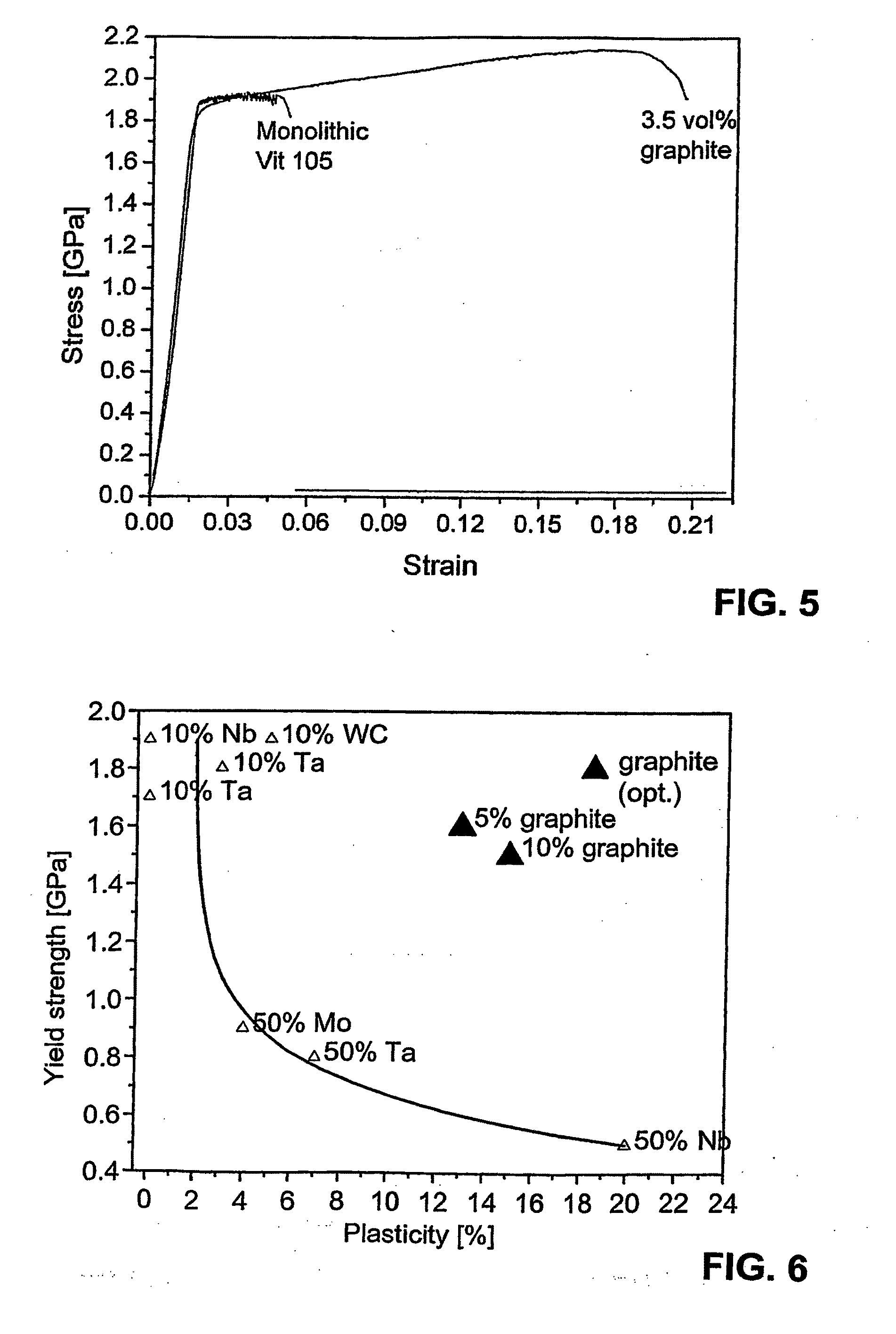

[0073]For achieving the goal of obtaining improved BMG-based materials, it is believed that foreign-particle reinforcement has the brightest future, because it allows easy reproducibility and direct tailoring of material properties. Foreign-particle-reinforced BMGs display, for example, better reproducibility of microstructure than in-situ-formed composites because the reinforcement microstructure and volume content are independent of processing parameters, in particular cooling rate. Similarly, while porous BMGs display a combination of high plasticity and yield strength, achieving a homogeneous pore distribution is very difficult. Monolithic BMGs with high poison ratios also appear promising, but the effect of enhanced plasticity has only been observed so far in a very costly Pt-based alloy. Foreign-particle reinforcement also has the great advantage that the microstructure and thus the material properties can be tailored. The latter can be adjusted by type, shape, size and volume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com