Filter Cap Additive Delivery System

a technology of additive delivery system and filter cap, which is applied in the direction of lubricant composition, filtration separation, separation process, etc., can solve the problems of less than optimal fluid conditioning performance, affecting the overall performance of the fluid-utilizing system or device, and gel particles breaking off, so as to achieve uniform additive release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

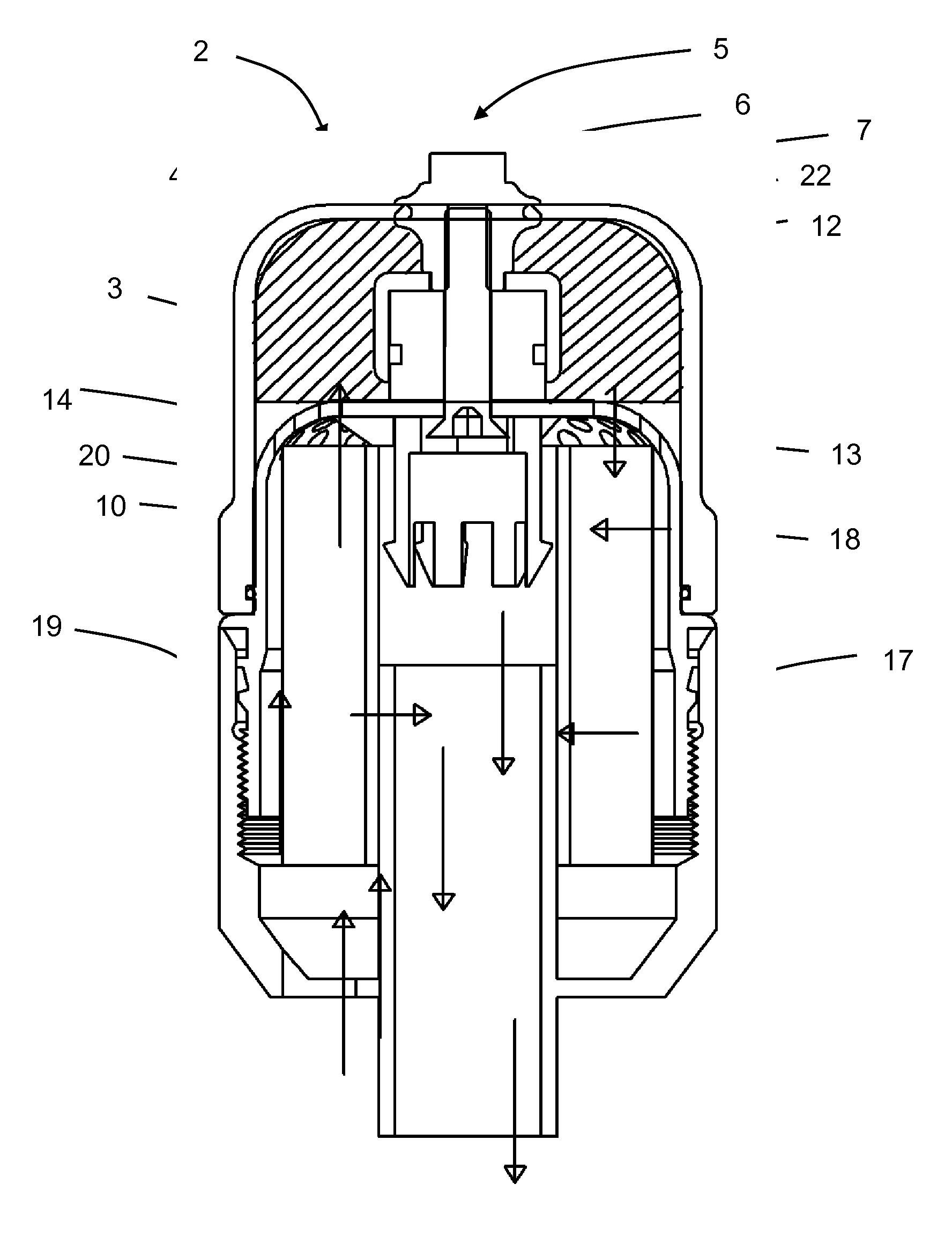

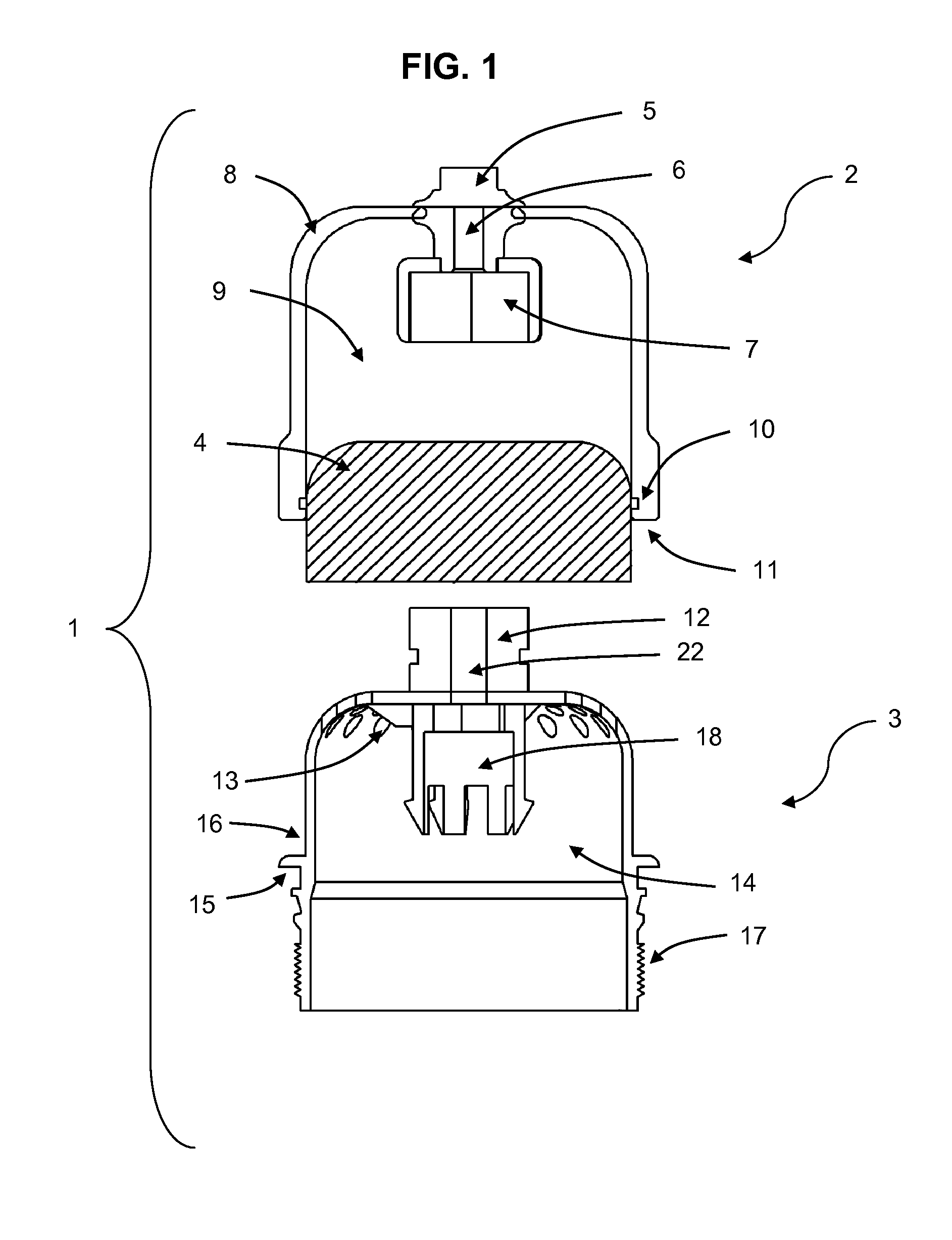

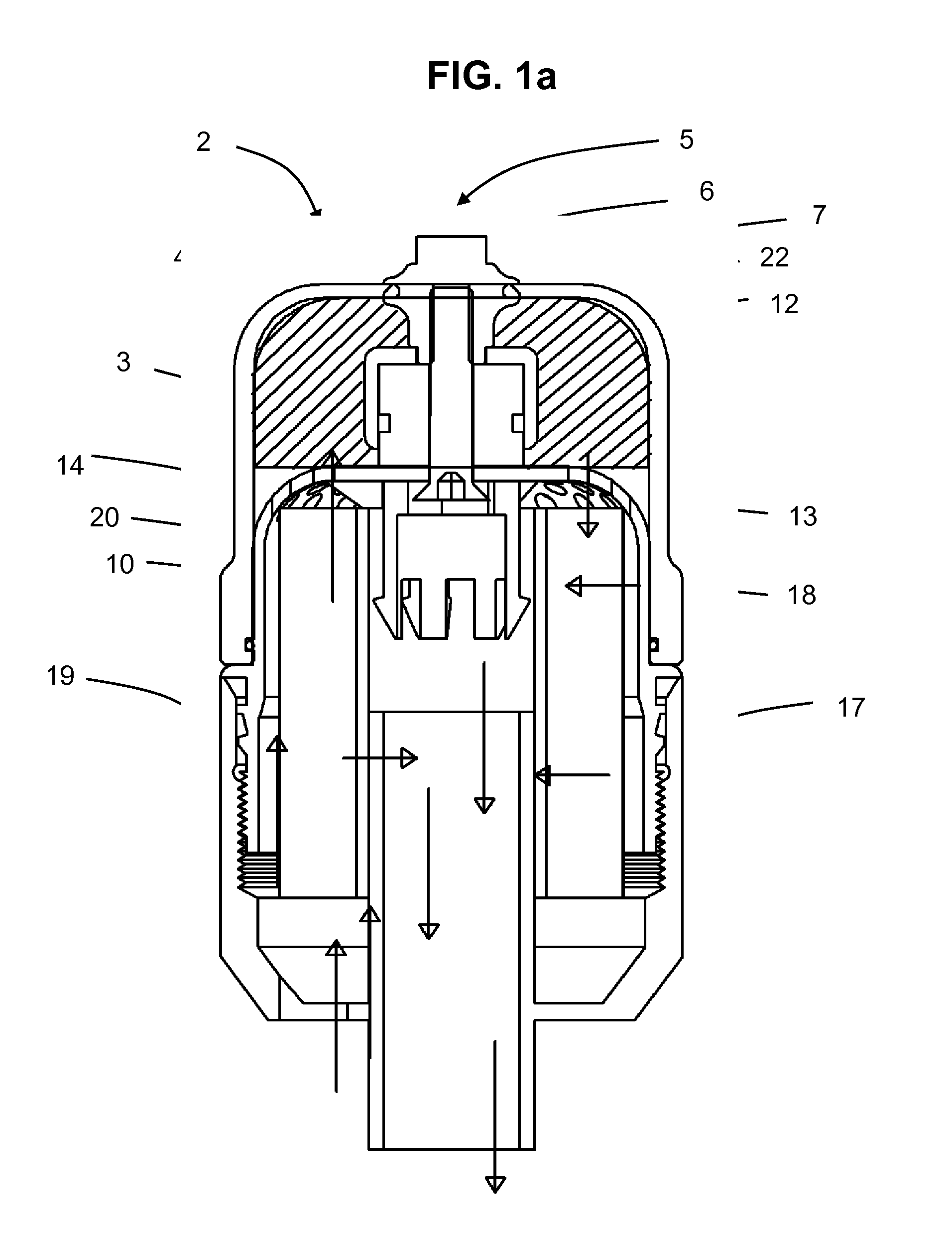

[0082]Into a container of the style shown in FIG. 7 and FIG. 7a, two equally spaced rows of 6 holes in each row, each hole measuring 5 mm in diameter, are drilled into the annular space wall. Into the annular space is placed a mixture of the following composition:

TABLE 1Composition of Additive GelPercent by WeightComponent13.2%Olefin copolymer viscosity modifier47.8%diluent mineral oil2.4%ashless polyisobutylene succinicanhydride dispersant maleic anhydridestyrene9.6%copolymer, partially esterified100.0%TOTAL

[0083]The mixture is heated at 100C for 8 hours to form a gel. The tilled additive gel filter cap is mounted onto a cartridge-style filter media insert and this assembly is fit into a cartridge-style filter housing, thus providing an additive delivery system of the present invention.

[0084]The assembled filter cartridge and housing is placed on a dynamometer equipped with a PSA DV6 engine and run for 100 hours. At the end of the test, oil analysis shows that an amount of viscosit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| physical integrity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com