Dental Light Guide

a technology of light guides and light sources, applied in the field of light guides and lightcuring equipment, can solve the problems of loss of light energy, ineffective light guides, and ineffective light sources such as tungsten halogen, metal halide, and xenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

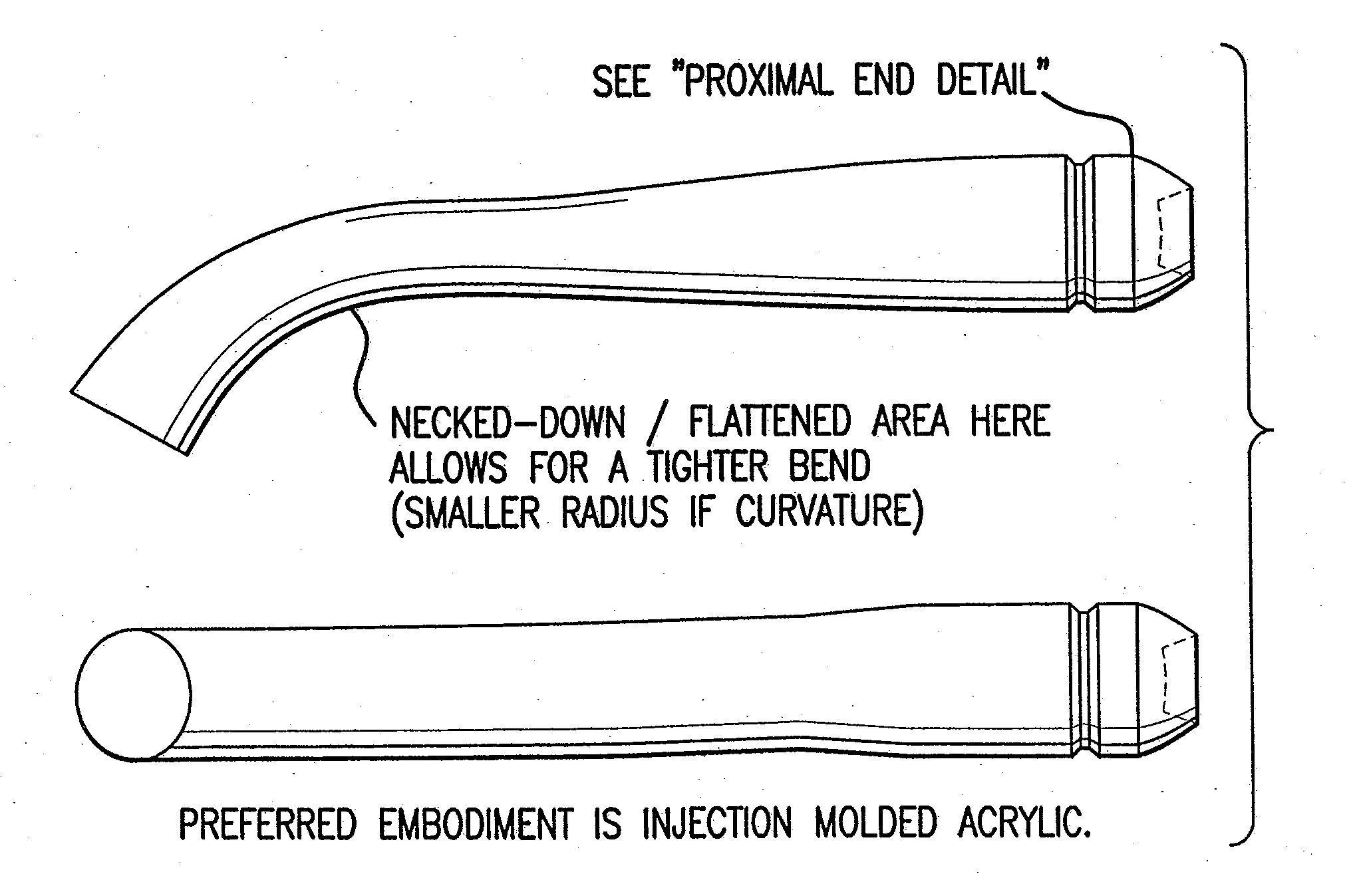

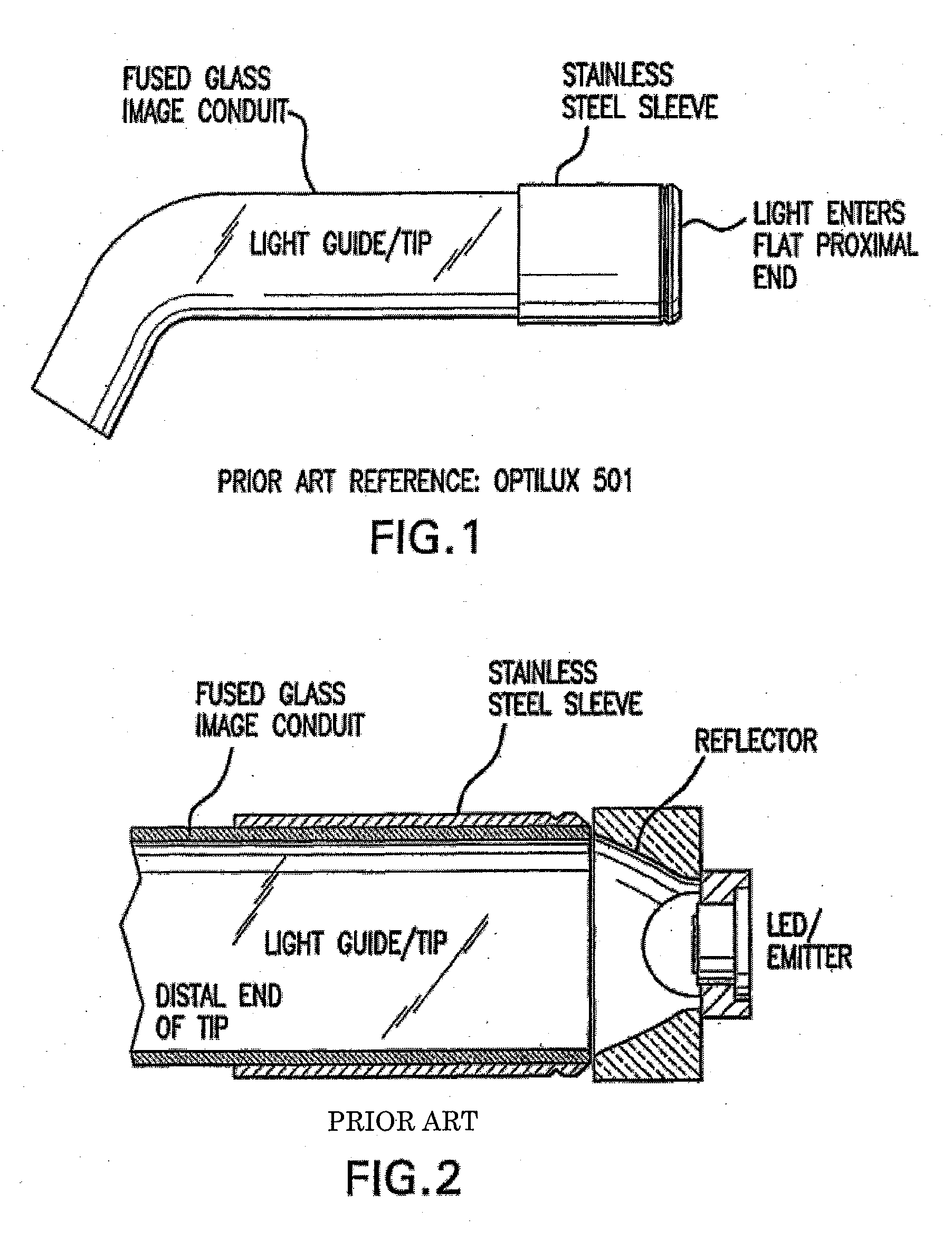

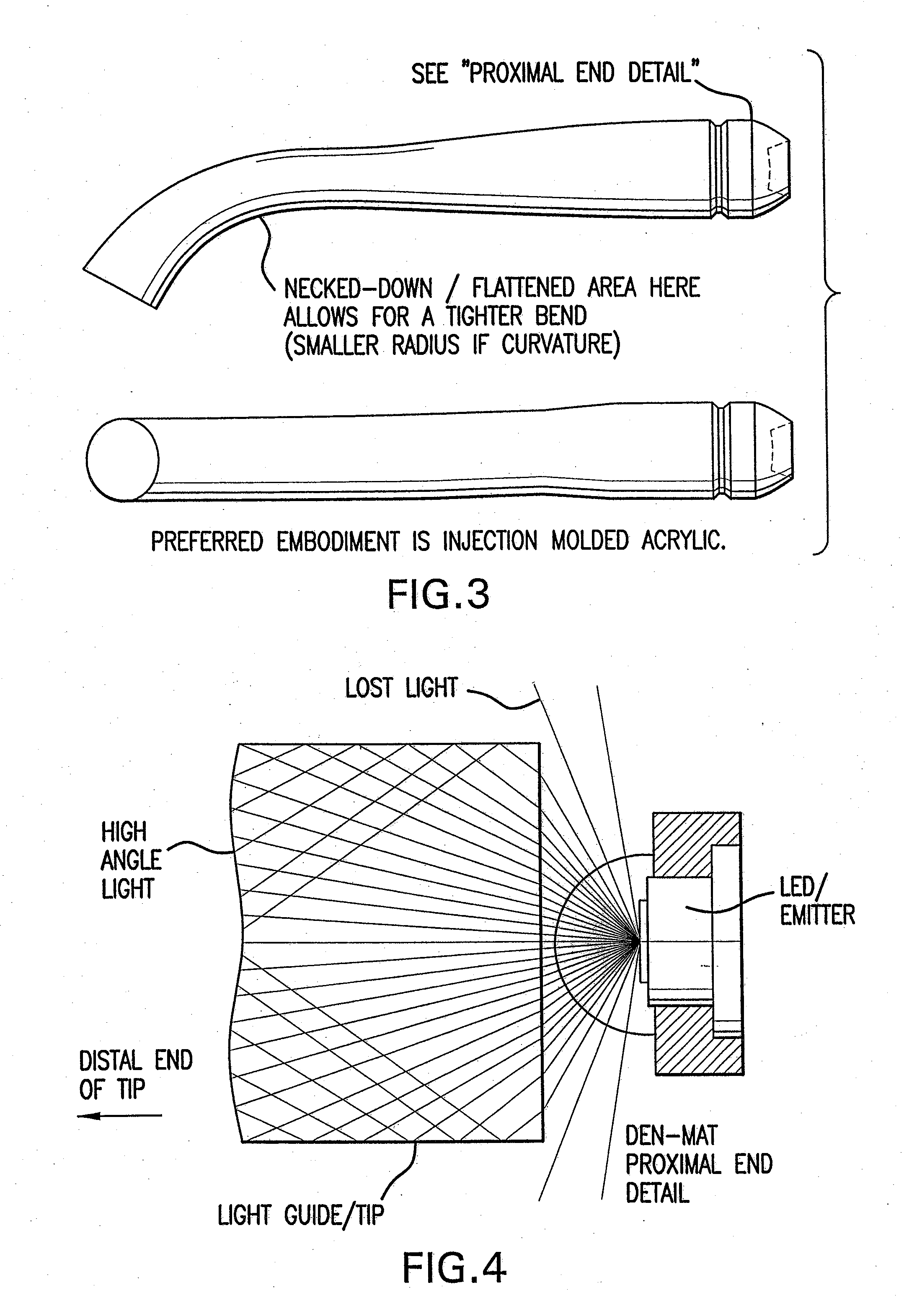

Method used

Image

Examples

example 1

[0050]It has been demonstrated that light intensity (mW / cm2) disperses rapidly with distance from these light sources. The exit angle of the light as it leaves the light source contributes greatly to this. As the beam spread increases the light looses intensity rapidly. This is clinically significant to the practicing dentist and their patients. The bottom floor of a typical preparation may be a minimum of 2 mm deep or more. If the light intensity is too low at the bottom of the filling the composite material may not receive enough energy to adequately cure. Even if the composite is placed directly on the surface of the tooth the dentist holds the distal end of the light guide approximately 2 mm away to keep the composite from adhering to it. The clinical advantage of the present invention is that the light intensity mW / cm2) increases at 2 mm away from the surface and stays higher as distance increases. This facilitates complete curing of the composite. The results of this experimen...

example 2

[0051]The effect of light collimation with an embodiment of the instant invention (identified in FIG. 11 as “Allegro”) on a composite (Heliomolar) that is hard to cure is shown in the FIG. 11. FIG. 11 also compares the embodiment of the instant invention to the other 3 best LED-curing lights on the market. The instant invention is clearly superior. The composite was cured at a distance of 6 mm. See FIG. 12. The vertical axis shows the hardness value. Knoop Hardness (KHN) is considered, by academics, the most accurate test of composite hardness. Greater hardness means the composite has polymerized to a greater degree. This improves strength and wear and decreases the likelihood of sensitivity. The bottom of the sample is actually 8 mm away from the distal end of the tip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com