Measurement apparatus and a method of using measurement apparatus

a measurement apparatus and measurement technology, applied in the field of industrial metrology, can solve the problems of reducing upfront cost, and achieve the effects of reducing financial risk, reducing upfront cost, and increasing the market for measurement probe systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

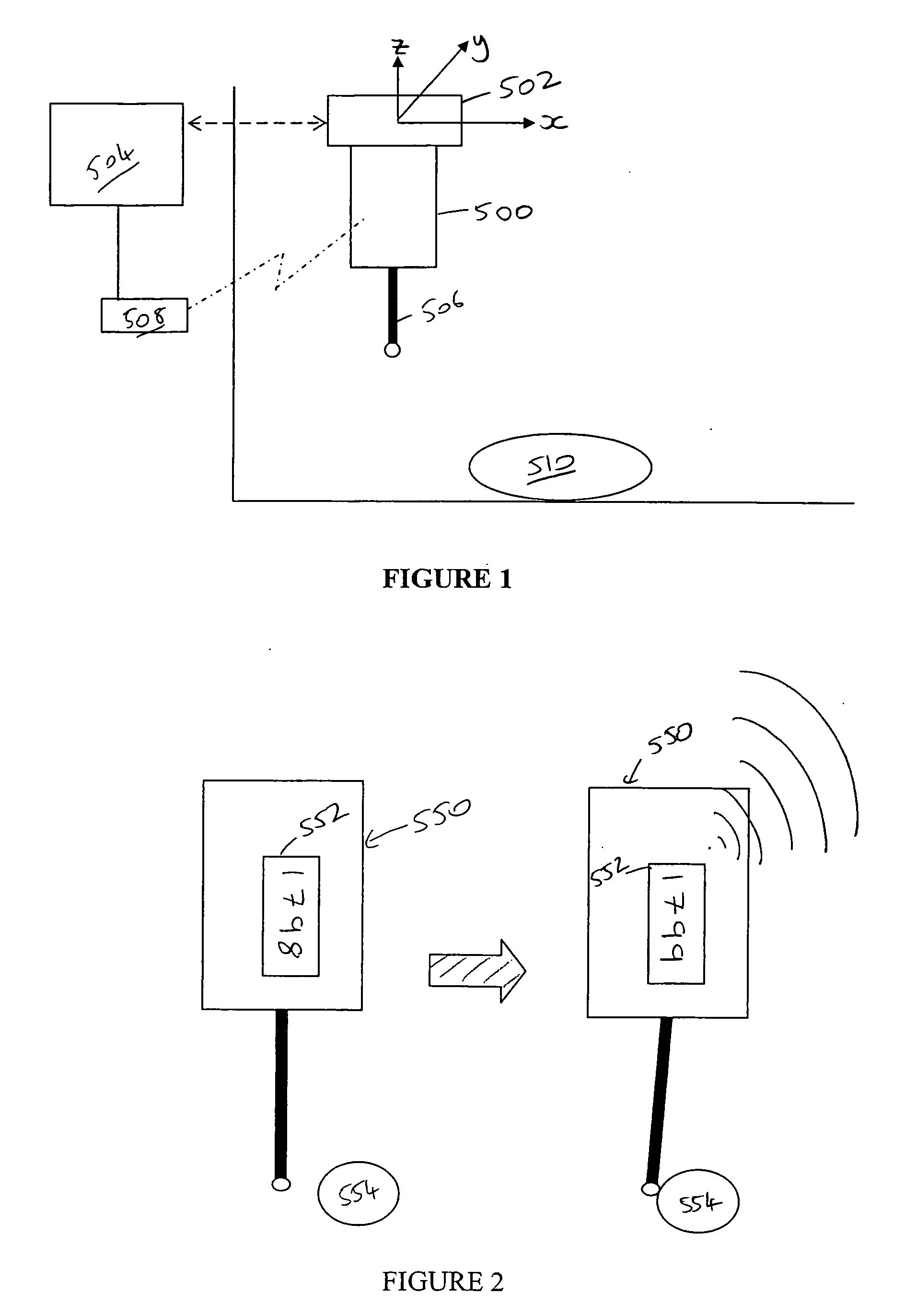

[0033]Referring to FIG. 1, a measurement probe 500 is shown mounted to the spindle 502 of a machine tool. The spindle 502 is moveable in three dimensions (X, Y, Z) under the control of a computer controller 504. The machine tool also comprises, in a known manner, various position encoders that accurately measure the position (in X,Y,Z) of the spindle 502 and pass such position information back to the controller 504. Various alternative types of machine tool are also known.

[0034]The measurement probe 500 is a touch trigger probe in which the stylus holder is attached to the probe body by a spring-loaded kinematic arrangement of the type originally described in U.S. Pat. No. 4,153,998, the contents of which are hereby incorporated by reference. In use, a workpiece contacting stylus 506 is brought into contact with an object 510 to be measured. Deflection of the stylus 506 unseats the stylus holder from the probe body thereby breaking an electrical circuit. A processor is provided as p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com